ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Bosch’s New Pitch Eyes €1B for Industrial Green Tech

Bosch has heightened up its endeavors to be in the forefront of promoting carbon-neutral production and Industry 4.0 initiatives. Particularly, it aims to further widen the sales ratio of its environment-friendly industrial products and solutions.

To illustrate, Bosch said it was able to generate €800 million of green tech sales for industry in 2021. This represents about 14 percent of the total sales of Bosch’s Industrial Technology business sector of €6.1 billion. In contrast, the global green tech market is growing 8 percent annually.

Therefore, Bosch wants to widen further the sales of green technologies for the industrial market to €1 billion in 2023.

“Bosch is growing faster than the market. By 2023, we want to break the one-billion-euro mark in sales of green industrial technology,” Rolf Najork, the member of the Bosch board of management responsible for industrial technology.

Ecological transformation is paying off: according to the VDMA, the association of German machinery and equipment manufacturers, the systematic use of green tech can cut industrial greenhouse gas emissions by almost 90 percent (VDMA, 2020). Furthermore, it also said that by 2050, the expansion of climate-friendly technologies in the industrial sector will rise to €300 billion a year.

Bosch presented its green technology solutions at the four-day Hannover Messe 2022, which opened Monday, May 30.

Industry Leads in Ecological Transformation

Earlier in 2020, Bosch become one of the first global industrial companies to achieve carbon-neutral production. Moreover, it is developing green technologies that conserve resources, reduce energy consumption, protect the environment, and mitigate global warming. “Industry will become a driver of ecological transformation in business and society. Bosch is mobilizing all its resources and contributing its technological know-how and many years of manufacturing expertise,” said Najork.

Najork added the industry now can play a crucial role in environmental and climate action. “Far from being a pipe dream, green factories are a reality. All we need now is more of them.”

Energy efficiency is a key lever, helping machinery and equipment to consume less energy.

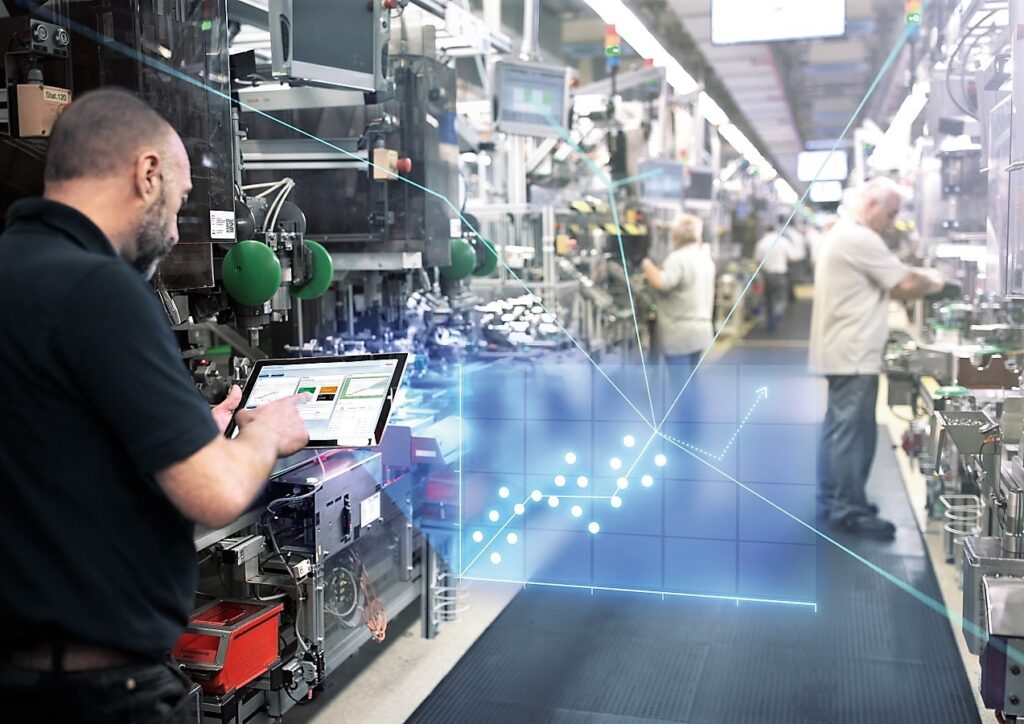

To manage heat, electricity, and compressed air consumption, Bosch relies on its own Energy Platform in combination with Nexeed Industry 4.0 software. This makes it easier to predict energy consumption, avoid peak loads, and recognize and correct deviations in individual machines.

Furthermore, the company deploys this platform to more than 120 of the company’s locations and in more than 80 customer projects. In Bosch’s Industry 4.0 lead plant in Hamburg, Germany, the software enables 40 percent energy requirement reduction per manufactured product. At its Eisenach plant, also in Germany, Bosch is currently piloting its Balancing Energy Network. Here, the AI solution manages and optimizes the energy requirement of 1,000 machines. The AI shows how production and logistics data, weather information, and energy prices relate to each other and offers recommendations for action. AI is expected to help further lower the location’s annual energy costs by around 5 percent.

Offers Efficiency, Higher Performance

Connecting machinery and processes intelligently and dovetailing them with information and communications technology creates the basis for energy-efficient production. Most importantly, this involves relocating functions from hardware to software, augmented by digital twins.

“In the factory of the future, it will be possible to adjust many things at the touch of a button,” said Najork. Here, Bosch takes a modular approach. The only static elements of such a factory will be the floor, ceiling, and walls. As a result, plant and equipment will last longer, and the amount of raw materials used in the production of new hardware will decrease. Digital twins provide ways of designing, developing, and testing production systems to make them more resource-efficient. “Virtual copies of physical assets in the real factory allow us to simulate and optimize workflows and processes – and this without interrupting operations,” Najork said.

For example, ctrlX Automation, the new Bosch Rexroth control technology, with its app technology and web-based engineering. This allows the volume of all automation components to be reduced by up to 50 percent on average. What’s more, the drives weigh up to one-third less. The lighter the hardware, the less drive power and energy are required. Three years on from market launch, more than 300 customers are already using this Bosch automation technology, which works like a smartphone.

The company is even rethinking hydraulics and unlocking its potential: machine tools, injection molding machinery, and presses often use smart hydraulic power units such as Bosch Rexroth’s CytroBox. The integrated variable-speed pump drive reduces energy consumption and electricity costs by up to 80 percent compared to conventional drives. CytroBox’s load-dependent control means that it is always in the optimum operating mode. It switches to standby mode when not in use.