ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Zignear Boosts Nidec’s AC Servo Motor for Industrial Robots

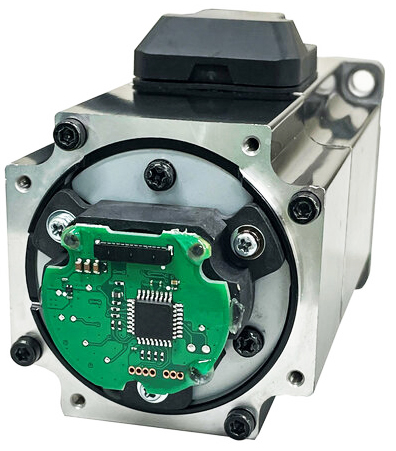

Nidec Corporation together with Nidec Sankyo Corporation have developed an AC servo motor with 17-bit resolution equipped with Zignear® technology. Zignear is the company’s proprietary position detection technology that can be applied to industrial robots and replace encoders.

AC Servo Motor

The new AC servo motor uses a similar number of components to a magnetic encoder. It also has similar location detection and tracking capabilities of an optical encoder. The AC servo motor highlights maximum accuracy in mechanical angles for location detection errors of less than ±0.02°.

Moreover, it can operate similarly to a conventional 17bit‐AC servo motor. This function has been demonstrated in a system test with a Zignear-equipped motor to drive an automated guided vehicle (AGV). Additionally, it uses a general-purpose microcontroller to accommodate a wide variety of output formats. Among them includes the ABZ phase output that is outputted by an optical encoder, and formats common in magnetic encoders, like serial.

The shape of the AC servo motor is identical to a conventional magnetic encoder, making easy replacements between the two. The new AC servo motor is intended for industrial robots and AGVs, among others.

Optical Encoder vs Magnetic Encoder

An encoder is a sensor used mainly to detect the rotation of a brushless DC motor. It is essential in adjusting a motor to an intended location and keeping its rotation consistent. Conventionally, a brushless DC motor requires an encoder. The reason is it has been difficult to detect its accurate location due to the “inconsistency” in the magnetic sensor. In particular, installation of a hall sensor and sensitivity could be factors. Now, however, after developing an algorithm that corrects such inconsistency, Nidec has successfully improved the location detection accuracy with the use of general-purpose microcontrollers.

An optical encoder tends to become larger in proportion to its accuracy, despite its high accuracy and capability to operate in a strong magnetic field. Thus, it requires precise positioning. Thus, optical encoder tends to be costly due to its code wheel and other components, and installation cost. Moreover, it has the tendency to deteriorate in an environment full of dust, oil, and others.

Meanwhile, a magnetic encoder operates even in a dusty environment. Also, as it works with a relatively inexpensive IC chip, it is cost competitive. However, the encoder’s accuracy is lower than that of an optical counterpart.

Zignear® Location Detection Technology

Nidec’s Zignear® location detection technology requires as small a number of components (hall sensor and microcontroller) as does a magnetic encoder. It uses software to maintain location detection and tracking capabilities that are equal to those of an optical encoder.

Going forward, Zignear®-equipped AC servo motors will contribute to meeting the needs for high-level accuracy, diverse forms of communication, and replacing conventional products in the fields of industrial robot and mobility system.