ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

5G, Automotive Spur New Demand for Circuit Boards

The production scale of electronic circuit boards, such as printed circuit boards (PCBs) and module PCBs continues to expand. That is, its expansion is a result of the continuing advancement of technologies.

The expansion and technological advancement are especially notable in automobiles, information and communications terminals, industrial equipment, and other growth fields.

Mega Trends Stir Growth

Accordingly, there has been earnest efforts for the automobile industry to meet the mega trend connected, autonomous, shared & services, and electric (CASE). Hence, this has been pushing up the demand for electronic circuit boards.

In addition, the full-scale deployment of fifth generation (5G) mobile communications has also contributed to the robust demand. Similarly, the expansion of internet of things (IoT) is also gathering steam.

Electronic circuit boards manufacturers will continue to expand businesses through technological development. In addition, they are also focusing on investment strategies in consideration of future needs and demands.

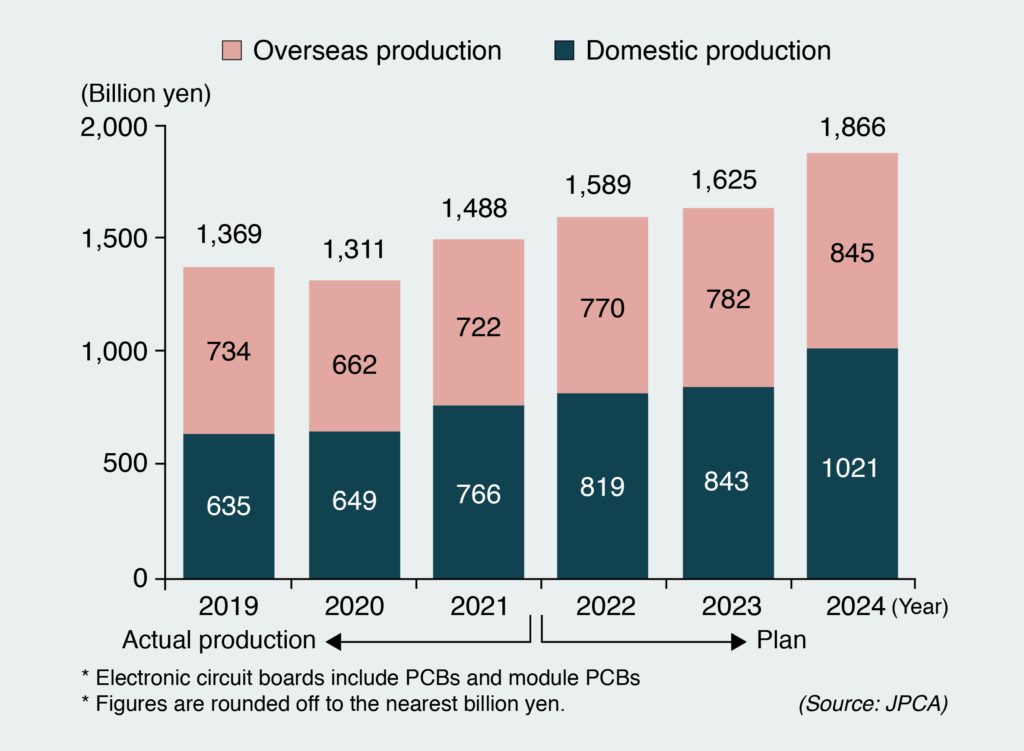

In its recent study, the Japan Electronics Packaging and Circuits Association (JPCA) said the combined domestic and overseas production of electronic circuit boards by Japanese companies in 2021 increased 13.4 percent year-on-year to ¥1.49 trillion. Most importantly, JPCA saw the significant increase as an offshoot of global economic recovery from the COVID-19 pandemic.

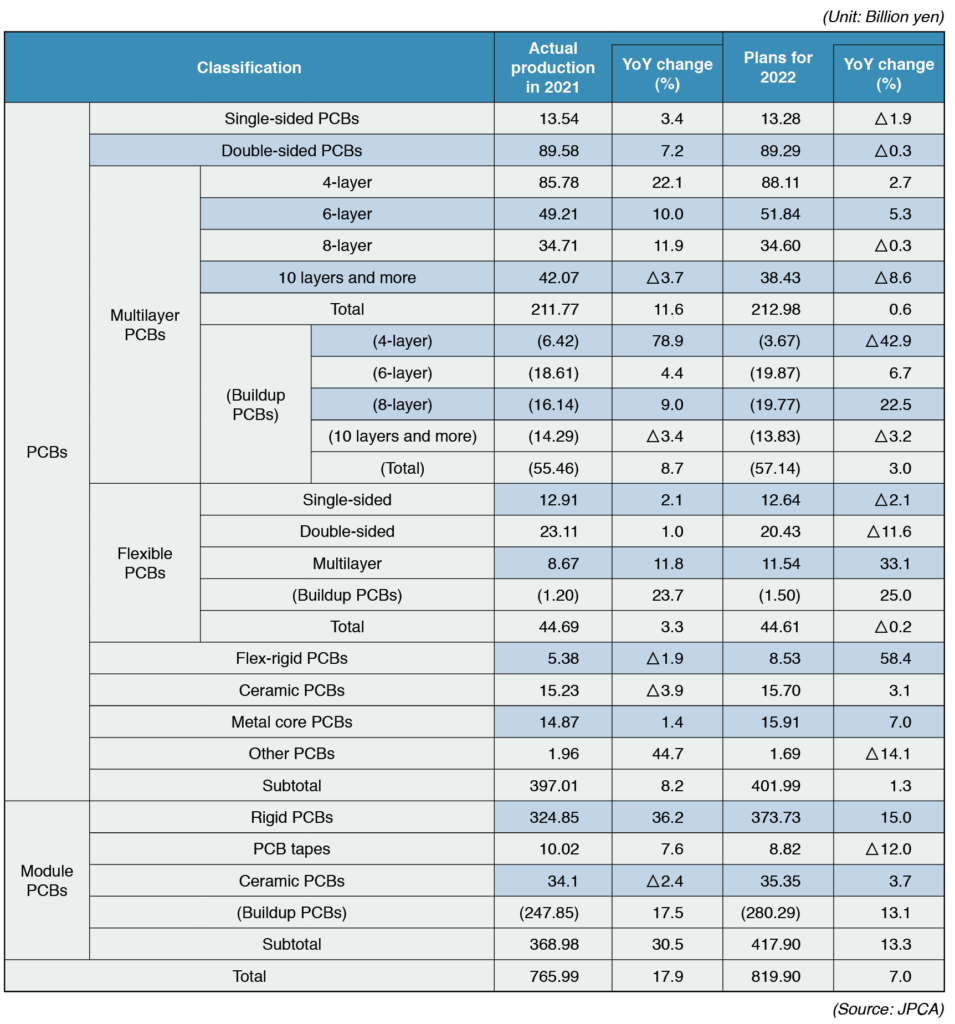

Particularly, in 2021, domestic production increased 17.9 percent year-on-year to ¥765.9 billion. On the other hand, overseas production rose 9.1 percent annually to ¥722.1 billion. Looking at domestic electronic circuit boards in 2021 by product type, amid the overall recovery trend, rigid module PCBs and multilayer PCBs showed strong growth.

Sustains Growth Trends

JPCA forecasted the total production of electronic circuit boards in 2022 by Japanese companies will increase 6.9 percent year-on-year to ¥1.5903 trillion. Hence, the industry will see continuous growth trend. By breakdown, domestic production will increase 7.0 percent annually to ¥8.199 billion, and overseas production will also increase 6.7 percent year-on-year to ¥770.4 billion.

Moreover, JPCA said positive growth will continue for both domestic and overseas production. The total production will likely reach ¥1.8665 trillion by 2024.

Buildup of high-density multilayer PCBs and rigid module PCBs will also exhibit double-digit growth in 2022. In addition, JPCA said the trend will continue two to three years later.

Communications infrastructure, computers, information terminals, and medical equipment are expected to drive the growth.

Revisits Investment Strategies

To meet the robust demand, electronic circuit boards manufacturers have been redoubling investment strategies to bolster their production capacities. They have been accelerating activities to build new plants and add new factories at their plants in Japan and abroad. Particularly, moves to increase investments in plants and equipment have been advancing, with sights set on battery electric vehicles (BEVs). For one, the BEV market will flourish around 2025.

For automobiles, the demand for PCBs for inverters, DC/DC converters, on-board chargers (OBCs) and battery management systems (BMSs) has been expanding. Moreover, metal core board, thick copper board, copper inlay board, and through hole thick copper plating technologies have been used in accordance with requirements.

With PCBs for smartphones, modules, semiconductor packages, high-density technologies have been advancing further. Any-layer PCBs for smartphones have advanced to those that apply microfabrication technologies with line/space (L/S) of 50μm/50μm or smaller. Furthermore, the introduction of the modified semi-additive process (MSAP) method, which enables finer patterns with L/S of 30μm/30μm or smaller, has also been progressing.

With module PCBs, component-embedded PCB technology has also been attracting attention. Particularly, this technology reduces the board area by embedding components to the inner layers of multilayer boards. In addition, components on the surface of PCBs as well.