ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

KUKA Establishes New 5G Campus Network

KUKA AG has established a 5G campus network at its Augsburg site in Germany. In particular, the automation specialist is incorporating the new wireless technology into product development and system planning. This arose as customers want more flexible production processes and secure, real-time communication between their machines.

According to the German Federal Network Agency, more than 200 frequencies have been allocated for local 5G networks by spring 2022. Specifically, the Augsburg-based robot and systems manufacturer has also secured the use of certain frequency ranges.

“This will enable KUKA to work on future products and solutions that exploit the potential of fast, reliable and secure 5G connectivity,” says Michael Wagner, Head of Control Technology in KUKA’s robotics division.

5G as Radio Standard in Large Production Facilities

For his part, Matthias Paukner, head of development for the EMEA region in KUKA’s systems engineering division, uses the campus network to build expertise in planning complex production systems.

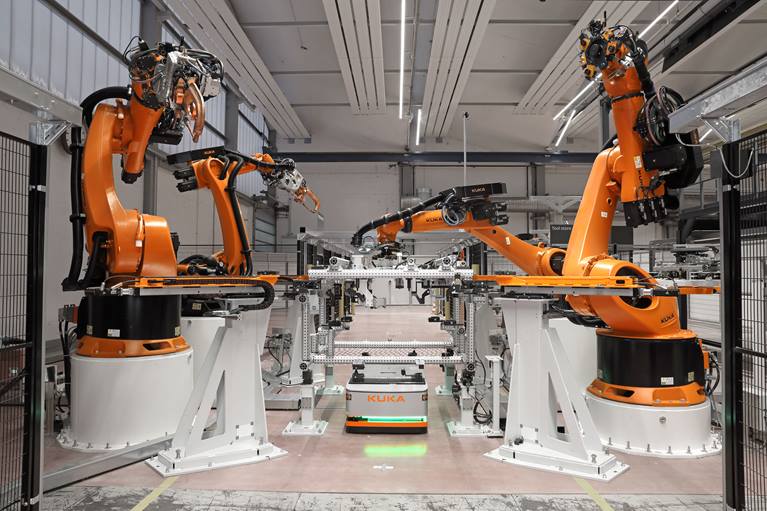

“The desire for flexibility is increasing. Many of our customers are increasingly relying on driverless transport vehicles in their production halls to deliver materials to the production line or flexibly transport parts from one machining station to the next for processing. 5G is tailormade for connecting the vehicles,” says Paukner.

New Radio Technology Suitable for Industry

Previous wireless technologies, such as WLAN or 4G, are often not sufficient for this. Transmission rates are too low and there is no guarantee that safety relevant data is transported fast enough. In comparison, 5G promises above all high bandwidth coupled with high reliability, which is essential in production. Any downtime results in a direct economic impact. “This offers our customers the opportunity to connect their production with a single radio technology. The current diversity of WLAN and 4G or even older technologies will thus be a thing of the past,” says Paukner.

The technology is constantly being further developed. International standardization organizations are responsible for this. People have been talking about 5G since Release 15. At that time, however, the focus was still on traditional mobile communications for private users. With Releases 16 and 17, the focus is shifting to real-time capabilities, reliability and energy consumption – topics relevant for industry.

KUKA Equips Test Facility with 5G

KUKA has already equipped a test facility in Augsburg with 5G technology. The Smart Production Center demonstrates how different products – from washing machines to bicycle frames to car body parts – can be produced in one and the same facility. “In our facility, we are using 5G to connect the mobile platforms, evaluating the advantages over connecting via WLAN,” says Paukner.

In the industrial environment, the range of functions will gradually increase in the coming years. Currently, the technology is in a developmental state and will initially be a supplement over the next few years. In the long term, 5G will replace the existing radio technologies.