ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

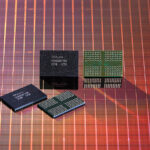

Unique EUV Metal Oxide Resist Key to Advanced DRAM

JSR Corporation has announced acceleration of its co-development with SK hynix Inc. Particularly, to apply Inpria, a JSR company’s Extreme Ultraviolet (EUV) metal oxide resist (MOR) for manufacturing advanced DRAM chips.

To illustrate, Inpria’s broadly-patented metal oxide photoresist platform for EUV enables customers to efficiently pattern advanced node device architectures. Inpria material solutions provide the performance needed to significantly reduce the cost of EUV. Moreover, these are compatible with proven processes and equipment configurations. Inpria’s MOR can suit standard spin coating process.

Critical Role in Lithography Processes

“EUV manufacturing is complex and requires cutting-edge materials,” said BK Lee, head of R&D process at SK hynix. “Tin-oxide resists show promise to deliver both on performance and also on lower manufacturing cost for the next generation of state-of-the-art DRAM.”

Meanwhile, Tadahiro Suhara, Managing Officer at JSR, said, “JSR’s technology has always been based on materials innovation.”

Suhara added the company aims to accelerate SK hynix’s technology roadmap by enabling efficient printing of the smallest features.

EUV is in use in commercial production in the most advanced lithography processes used in semiconductor manufacturing. Most importantly, as the industry moves to smaller critical dimensions in chip manufacturing, its use will likely increase substantially.

Inpria is the leader in metal oxide EUV resists and has achieved the world’s highest resolution using EUV exposure systems. JSR acquired Inpria in 2021. Furthermore, the company is investing to expand production capabilities and support customers for high volume manufacture.