ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

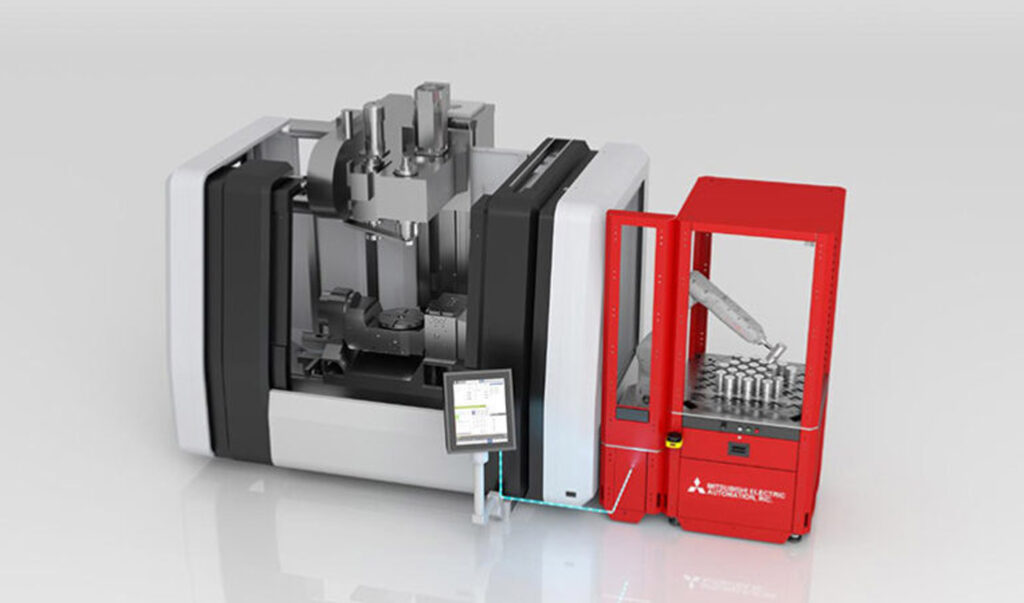

Mitsubishi Electric Pitches New Machine Tending Solution

Designed for easy set-up and use, Mitsubishi Electric Automation Inc.’s comprehensive offering of machine tending solutions provides manufacturers with the answer to labor shortage challenges while improving productivity and lowering operating costs.

Mitsubishi Electric offers the LoadMate PlusTM machine tending product line. It is an engineered solution that is easy to implement. At the same time, it offers flexibility and mobility to address the labor shortage issues throughout the manufacturing sector.

Specifically, machine tending is the process of loading and unloading parts or materials into a machine tool center. Machine tending commonly works with vertical machining center mills and turning centers (lathes). Among them include CNC Swiss Machines.

Rising Demand for Automation

Automation is becoming increasingly attractive to manufacturers due to labor shortages and pressures to maximize productivity. Machine tending enables flexible connectivity via Ethernet and easy programming through the Direct Robot Control (DRC) feature of Mitsubishi Electric’s M8 Series. As a result, it benefits customers that may not have experienced robot programmers available. In addition to DRC, almost any CNC machine can be connected to a shop floor. This is possible via discrete I/O for non-M8 CNC controls from Mitsubishi Electric and other companies. Further support is available through Mitsubishi Electric trained engineers to service both robot and CNC. Additionally, Mitsubishi Electric Automation offers a 5-year robot maintenance and warranty program.

“Mitsubishi Electric Automation Inc.’s machine tending solutions portfolio provides a cost-effective answer to ongoing labor shortages and maximized productivity challenges many manufacturers are currently experiencing. Our experts work closely with the customers’ team to find and implement a turn-key solution that is seamlessly integrated, fully supported, and delivers ROI quickly” said Dave Simak, service product manager at Mitsubishi Electric Automation.