ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

FA, Mounter Makers to Roll State-of-the-Art Factories

Japanese mounting machine and factory automation (FA) companies are building state-of-the-art factories by adapting digital manufacturing technologies. They are well on their way to start operation between 2024 and 2025. Accordingly, higher production of machinery and equipment is highly likely. The construction of the new plants came about amid the expected higher demand for electronic devices from new industry trends. Among them include 5G, electric vehicles (EVs), digital transformation (DX), and new energy that promotes carbon neutrality.

FUJI Corporation is constructing the new Okazaki plant building (Okazaki City, Aichi Prefecture) to expand its mounting machine business. The new plant will start operation in September 2024. The building will be a four-story structure with a total floor area of 32,500sq.m. The company will invest approximately 10 billion yen for the new building. It will be a state-of-the-art factory that will feature robotics and IoT technologies. When completed, its production capacity will be 1.5 times that of the previous facility.

Joji Isozumi, President and Chief Operating Officer of FUJI, said, “Digital manufacturing will enable us to operate with less risk in the face of fluctuating demand. Local production for local consumption in the manufacturing industry is progressing. Thus, we will prioritize production in Japan to cope with the moving out of intellectual property. Also, we will shorten delivery times by utilizing local inventories through our worldwide network of distributors,” said Isozumi.

Presently, Yamaha Motor Co., Ltd. is expanding and renovating its Hamamatsu Robotics Office (Kita-ku, Hamamatsu City), which manufactures mounting machines and industrial robots. The construction of Hamamatsu Robotics Office is scheduled for completion in June 2024. The total floor area of the office building will be approximately 82,000sq.m, that is, 1.6 times the current floor area. Meanwhile, the production area will increase 1.8 times, while the production capacity of surface mount machines will double.

Other FA companies are also aggressively investing in Japan. For one, Mitsubishi Electric Corporation is infusing large investments in Japan to expand its FA control systems business, which is one of its priority growth areas.

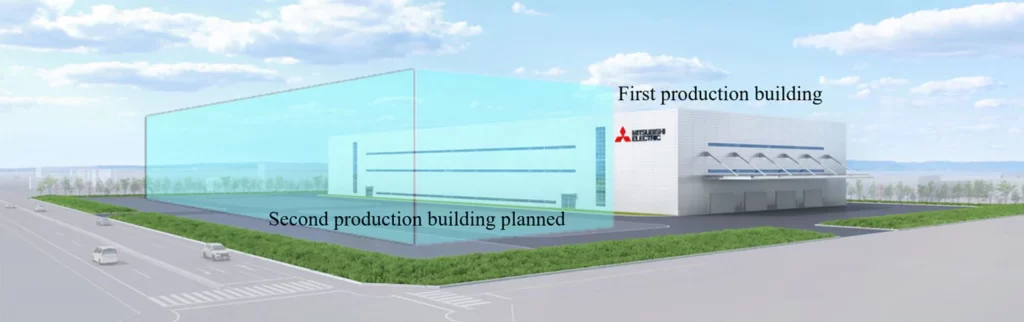

The company’s domestic production bases for FA business are Nagoya Works (Higashi-ku, Nagoya City) and Industrial Mechatronics Systems Works (Higashi-ku, Nagoya City). Currently, the company is constructing a new production base (site area of 42,000sq.m, total floor space of 33,600sq.m) in Owari-Asahi City, Aichi Prefecture. It earmarked an investment of approximately 13 billion yen to strengthen its FA control systems business. Specifically, it focuses on digital-related fields such as semiconductors, electronic components, and data centers as well as decarbonization-related fields such as lithium-ion batteries. Additionally, the company is currently constructing a new production facility (site area: approx. 42,000sq.m, total floor space: approx. 33,600sq.m) in Owariasahi City, Aichi Prefecture.

Moreover, an additional investment of approximately 42.5 billion yen (cumulative total of approximately 55.5 billion yen) is for the construction of a second production building and investment in production facilities. The first production building will start operation in April 2025, and the second production building in April 2027.

Yaskawa Electric Corporation is building a new robot machining plant to strengthen its production capabilities. The new plant is scheduled to start operation in May 2024. The company targets to automate the assembly process for large-capacity models through the reorganization of domestic business sites in its inverter business.

Specifically, the Yaskawa Solution Factory carries out production activities while implementing the “i3-Mechatronics” automation solution concept based on digital data management at manufacturing sites. The Yaskawa Solution Factory was established at the Iruma Plant (Iruma City, Saitama Prefecture).