ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ASMPT’s New Software Enhances SMT Process

The new SMT Analytics software from ASMPT evaluates the SMT process in detail by identifying and locating problematic aspects that often go unnoticed. In fact, some of them can lead to shortfalls in efficiency and performance. The innovative software helps employees detect the causes of trouble, highlights potential losses, and points out potential improvements.

Every line is unique in today’s SMT production. Moreover, the many different configurations and far-reaching technical interrelationships within the production lines make them highly complex systems. Low performance can have many causes such as logistical obstacles, inefficient staff scheduling, or machine-related problems.

Why does producing this batch suddenly take 30sec when it used to take only 25sec? To answer such questions, it is helpful to perform an analysis in the overall context of the SMT production process to show which factors really cause the loss of productivity. This calls for experienced employees who over time have developed a ‘feeling’ for why things are not working as they should. However, not everyone has such specialists.

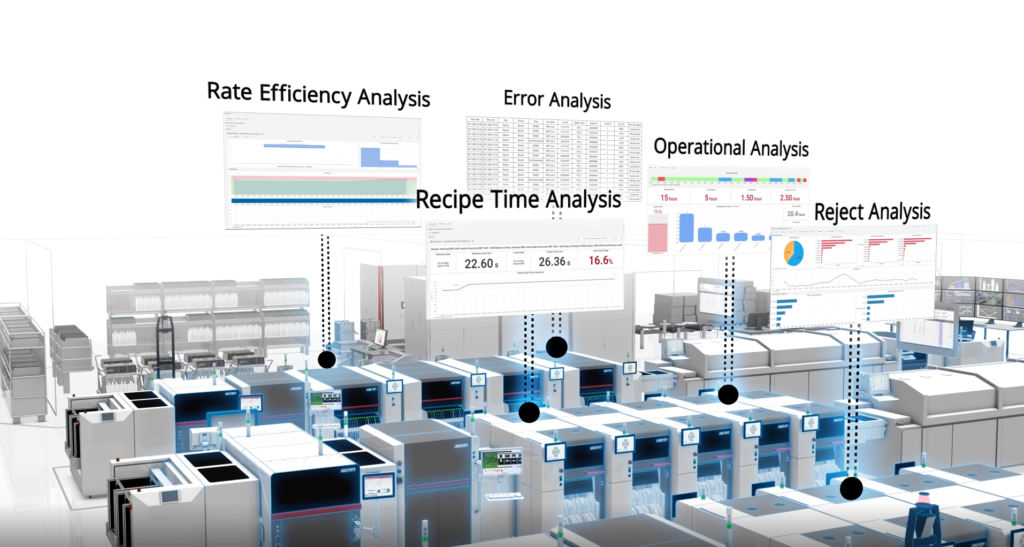

Performing in-depth analyses is now possible with SMT Analytics from ASMPT, which runs stream analytics based on the latest data processing technologies. Furthermore, the innovative application features a variety of dashboards for descriptive analyses based on user profiles and process structures.

In addition, clearly defined use cases help to monitor important KPIs, locate the root causes of problems, and present historical, real-time, and reference data in a structured and correlated manner. True to ASMPT’s open automation concept for integrated manufacturing, SMT Analytics will also be able to handle third-party systems soon.

Real-world use cases and dashboards

Electronics manufacturers can use SMT Analytics to get to the bottom of time-, condition- and material-related problems. Moreover, maximize their throughput with a wide range of usage scenarios.

With its time-based analysis, SMT Analytics makes slowdowns and shortfalls visible through intelligent data correlation. The software not only detects and prevents immediate performance shortfalls but helps to optimize processes in the long term by analyzing changes in cycle times. With its condition analysis, SMT Analytics offers additional important use cases for maximizing performance.

In the next version, detailed statistics on production availability as well as the status of placement areas, lines, and systems will be available. This will provide employees with clear insights into where changes or shortfalls are occurring. The software also analyzes downtimes resulting from malfunctions and provides detailed information on their causes and durations.

By pinpointing the information down to the specific placement area, employees can take targeted measures against throughput shortfalls. In addition, SMT Analytics enables employees to gain a better understanding of component quality as well as operating and supply processes. Furthermore, with its total reject rate, it displays peaks that have occurred over time.

”As a technology and market leader, ASMPT has focused on improving performance on the shop floor for many years,” says James Leather, Director IoT Solutions at ASMPT.

In addition, Leather pointed out ASMPT is intimately familiar with the entire SMT production process. “With SMT Analytics, you bring the knowledge that we have accumulated over many years into your company. We will continuously expand SMT Analytics with further functionalities and accompany our customers on their journey to the intelligent factory.”