ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

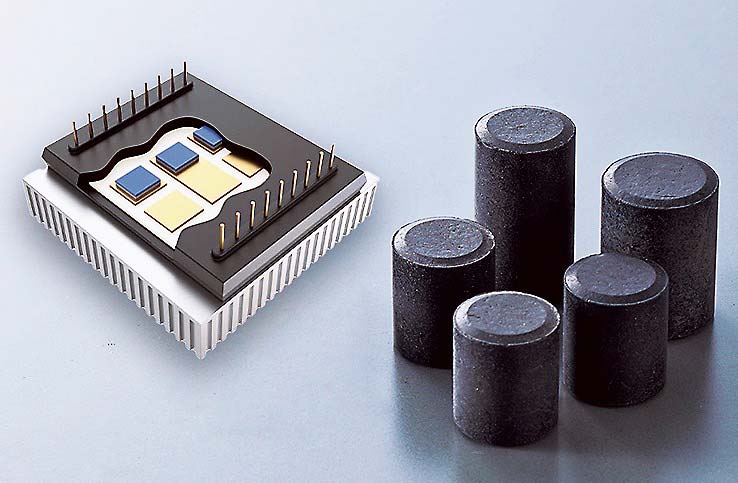

Sumitomo Bakelite's New Resin Suits SiC Power Modules

Sumitomo Bakelite Co., Ltd. has developed an epoxy encapsulating material featuring high glass transition temperature (Tg) for next-generation silicon carbide (SiC) power modules.

Primarily, the company’s resin improves the heat resistance of power modules. Thus, it contributes to the miniaturization and improvement of functionality of power modules. Also, the company aims to make it the global standard for resins for SiC power modules.

Mainly, power modules are important devices that enable efficient use of electricity, reduce energy consumption, and maximize equipment performance. Particularly in the automotive industry, the supply voltage of batteries increases. This resulted from the increasing demand for battery electric vehicles (BEVs). Also, the replacement of silicon (Si) by SiC as the main material for power module chips as it provides even more functionality, contributes to this trend.

Electrified vehicles (xEVs), which reduce CO2 emissions while driving, are on the rise globally. SiC is attracting attention as the main material for power module chips that can handle higher voltages.

Compared to Si, SiC has superior features such as high energy efficiency, high voltage resistance, and high temperature resistance. To fully exhibit these functions, semiconductor encapsulating materials need to have even higher heat resistance.

Higher Glass Transition Temperature

The glass transition temperature of an epoxy resin varies depending on the type of resin. Improving the crosslinking density of the resin can raise its level, but generally, Tg ranges from 100 to 200֯C.

The high-Tg epoxy encapsulating material for next-generation SiC power modules has been developed by making the main chain skeleton of the resin more rigid. In addition, the company has increased the normal crosslinking density, thus achieving a glass transition temperature that reached 240֯C. Furthermore, the company implemented a unique approach by combining resin formulations and fillers, successfully turning it into an epoxy sealing material.

In addition, by optimizing the type of curing agent that reacts with the epoxy resin, Sumitomo Bakelite was able to avoid hardness and brittleness as physical property after curing. It confirmed that the product has stress relaxation performance that prevents defects during the power module assembly process.

The company has started providing samples of the new-grade high Tg epoxy encapsulant material for next-generation SiC power modules for customer evaluation, with mass production eyed beginning fiscal year 2025.

This is a translation of a Japanese article originally published in Dempa Shimbun Daily.

-05 July 2024-