ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Innovative System Boosts Optimized Display Production

Aerotech’s tightly integrated systems enable display manufacturers to drive quality, throughput, and control cost per display altogether.

Through the years, displays have continued to play an important role in various industries and the market has diversified to adapt to changing landscapes and technological innovations.

Traditional applications of display panels include TVs, personal and notebook computers, and smartphones. They are also used in information-sharing devices used in other industries such as retail, transportation, healthcare, and education.

A recent report by MarketsandMarkets Research Ltd. said the global display market is expected to reach US$173.7 billion by 2029 from US$135.2 billion in 2024. Although industries such as retail are likely to experience a decline in demand for displays due to shift towards online advertisement and shopping, opportunities remain high in the smartphone industry post 5G rollout as well as in the automotive segment. Moreover, the continuing evolution of technologies in display panels to meet emerging application trends also provide solid profitable outlook.

As an output device, display panels need to complement advancements of electronic devices, not just from technological standpoint but also in precision and quality from an optimized, cost-effective manufacturing viewpoint as well. In fact, a significant part of display making process is the display cutting process, which is a crucial aspect in meeting display manufacturers’ goal of an optimized display production.

In this interview with AEI, Travis Schneider, Business Development Manager at Aerotech discusses the role of high-performing automation systems in helping manufacturers achieve a truly optimized production.

AEI: Can you discuss the prevailing market condition of displays from Aerotech’s point view as a high-precision automation systems provider?

Schneider: The display market is shaped by a clear push for better performance—higher resolution, quicker refresh rates, and sleeker designs—but also by constant pressure on cost. This presents a significant challenge for manufacturers, particularly given the scale of global production. In 2023, it is estimated that around 1.2 billion displays were sold for mobile phones, TVs, monitors, and automotive displays. This translates to approximately 38 units being produced every second.

AEI: In cutting displays, what are the crucial elements automation systems should have to achieve high performance, optimized yield?

Schneider: Manufacturers cutting both small and large-format displays typically pursue three key objectives: increasing throughput, maintaining quality, and reducing unit cost.

Throughput is often the top priority, particularly in high-volume production environments. The goal is to cut as many displays as possible within a given time frame.

Quality is also critical and is defined by the ability to maintain tight part tolerances. As device designs become more compact, the need for precision increases.

Cost per display is the third essential consideration. To remain competitive, manufacturers aim to lower the cost of each unit cut without compromising quality. This means optimizing both speed and accuracy to improve yield while minimizing waste and operational costs.

In short, a high-performance cutting system must deliver speed, precision, and cost-efficiency – all at once. Only by meeting these three requirements in parallel can manufacturers achieve truly optimized production.

AEI: What are the critical factors manufacturers need to consider in cutting displays to achieve these three core objectives?

Schneider: High-precision motion systems play a key role in several core processes within display manufacturing, such as laser lift-off, laser-induced forward transfer, cutting, trimming, and drilling. These laser-based techniques are widely used because they offer a combination of speed and accuracy.

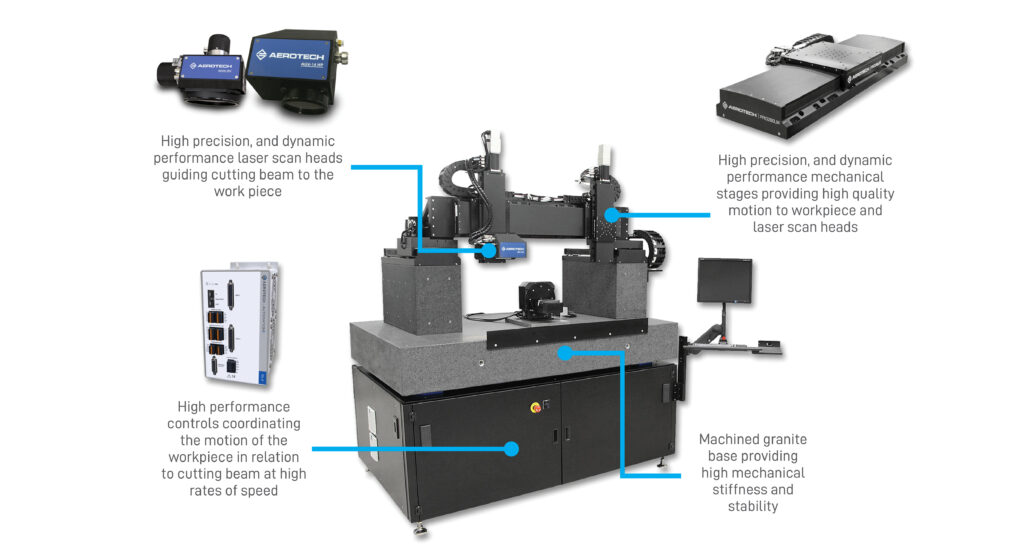

In practice, manufacturers are increasingly aware that meeting throughput, yield, and cost targets requires more than optimizing individual parts. True process optimization comes from a systems-level approach—where motion hardware, laser scan heads, mechanical structures, and control platforms are designed to work in sync.

Several factors influence how well such a system performs. The machine base must be rigid enough to suppress vibrations, especially during high-speed operations, preventing mechanical resonances from introducing error. Motors and stages need to be properly sized to provide the necessary torque or force relative to inertia—ensuring fast acceleration and deceleration without compromising positional accuracy. Laser scan heads, often built around galvanometer-driven mirrors and F-theta lenses, must deliver high spatial resolution and low dither to guarantee precise spot placement.

Additionally, fast, tightly coordinated servo control loops are essential to keep the beam aligned with its intended path, particularly when operating at high speeds.

These are well-established principles—but many commercial solutions struggle with integration. When motion and laser subsystems come from different sources, inconsistencies in timing and control can impact performance and limit throughput.

AEI: What are the compelling elements of Aerotech’s platform that meet the needs of display manufacturers?

Aerotech specializes in delivering tightly integrated systems that combine precision motion control with advanced laser processing. Both are essential for high-performance display manufacturing. While many solutions combine off-the-shelf components, Aerotech designs both hardware and software in-house, ensuring every element works together as a unified system that meets the demands of speed, accuracy, and reliability.

A key feature of this system is a high-bandwidth fiber-optic motion bus, which provides real-time communication between laser scan heads and motion stages. This enables precise coordination between beam and substrate, both in time and space—an important factor in applications where micrometer-level accuracy must be maintained at production speeds.

Aerotech also offers a range of software tools developed specifically for laser-based processes. Infinite Field of View (IFOV) expands the working area by seamlessly moving across multiple fields of view, allowing for consistent results across large panels without stitching errors. Position Synchronized Output (PSO) triggers the laser based on actual position data rather than time, improving placement accuracy. Enhanced Tracking Control (ETC) corrects for motion disturbances in real time, and Drill Optimizer streamlines high-speed, point-to-point movements to improve efficiency in dense drilling tasks.

AEI: What sets Aerotech’s apart from your competitors?

Schneider: What sets Aerotech apart is its focus on integration. Every capability, from mechanics and controls to software and laser coordination, is developed with the full system in mind. These tools are shaped through close collaboration with equipment builders and manufacturers to help address real-world production challenges, not just technical requirements.

Aerotech’s strength lies in overcoming systems integration challenge. Ours are designed from the ground up to synchronize motion control and laser delivery within a single, unified architecture. This high level of coordination enables manufacturers to maintain micrometer-level tolerances, boost throughput, and control cost per display simultaneously.

Ultimately, success in precision display manufacturing is not just about assembling the right technologies. It is about making them work together seamlessly—and tailoring them to the specific demands of the application.

AEI: With this integrated motion control system, is it actually possible for display manufacturers to achieve product performance and quality but still minimize operational costs?

Schneider: Achieving both high product performance and quality while lowering cost is often seen as a challenge in display manufacturing. However, with the right approach to system integration, it becomes a realistic goal.

The key lies in coordination, not compromise. When motion stages, laser scan heads, and control platforms are designed as a unified system, manufacturers can maintain sub-micron tolerances, increase process consistency, and boost throughput. This level of integration not only improves yield, but also reduces variability and rework, directly contributing to lower cost per unit.

Aerotech’s platform is built on this principle. By synchronizing motion and laser control within a single architecture, our solutions help manufacturers meet the dual challenge of delivering quality at scale—without letting cost spiral out of control.

In short, high performance and cost efficiency aren’t opposing goals. With the right system design, they reinforce each other.

07 August 2025