ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Aerotech Sees AI, 5G to Sustain Motion Control Growth

The past year has shown geopolitical and macroeconomic uncertainties continue to hound the global market in diverse magnitude across many industries. Particularly, the electronics and semiconductor industry and its related ecosystem are no exception.

Most, if not all, of the industry’s products rely heavily on market demand for the end products. Thus, the purchasing power of the consuming public will have to factor a lot into the production curve of the industry.

Despite the market volatility and challenges, Aerotech Inc. was able to demonstrate remarkable resiliency and adaptability in the past year. Richard Teo, APAC Director for Aerotech Inc., gave credit to the company’s robust portfolio and presence in various industries. Moreover, the emergence of megatrends has been propelling the demand for the company’s motion control technologies.

“It has been advantageous for Aerotech that more companies are recognizing the value of precision, accuracy, and high throughput. The growing adoption of digital, high-end solutions, coupled with the increasing emphasis on artificial intelligence, has not only created new opportunities but also spurred a surge in demand for our cutting-edge motion control technologies,” said Teo.

“This positions Aerotech favorably for continued growth.”

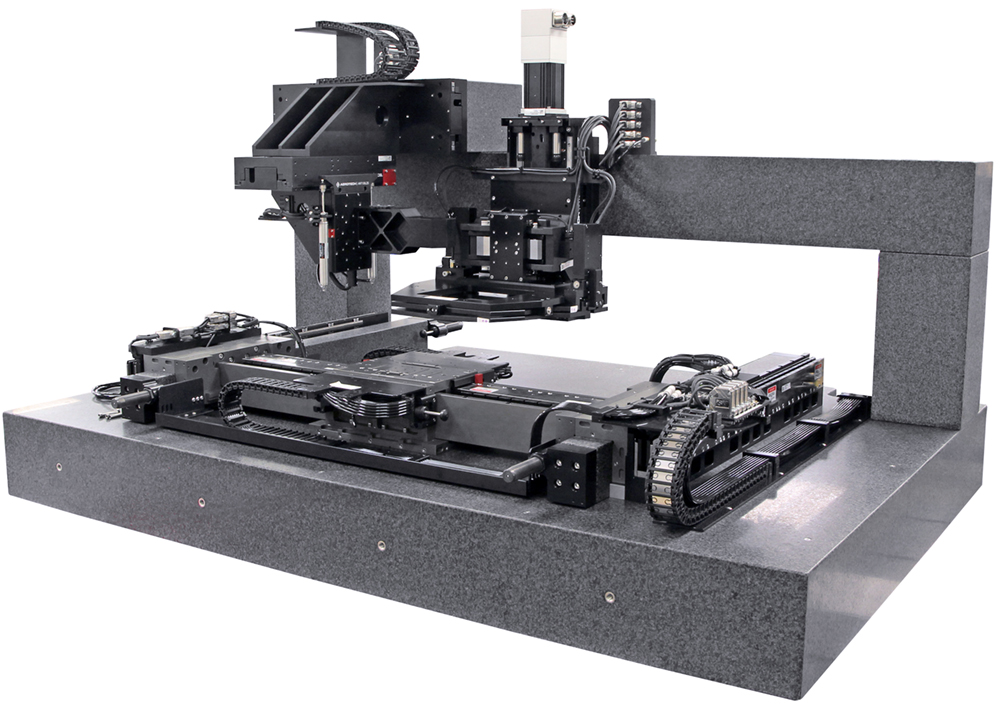

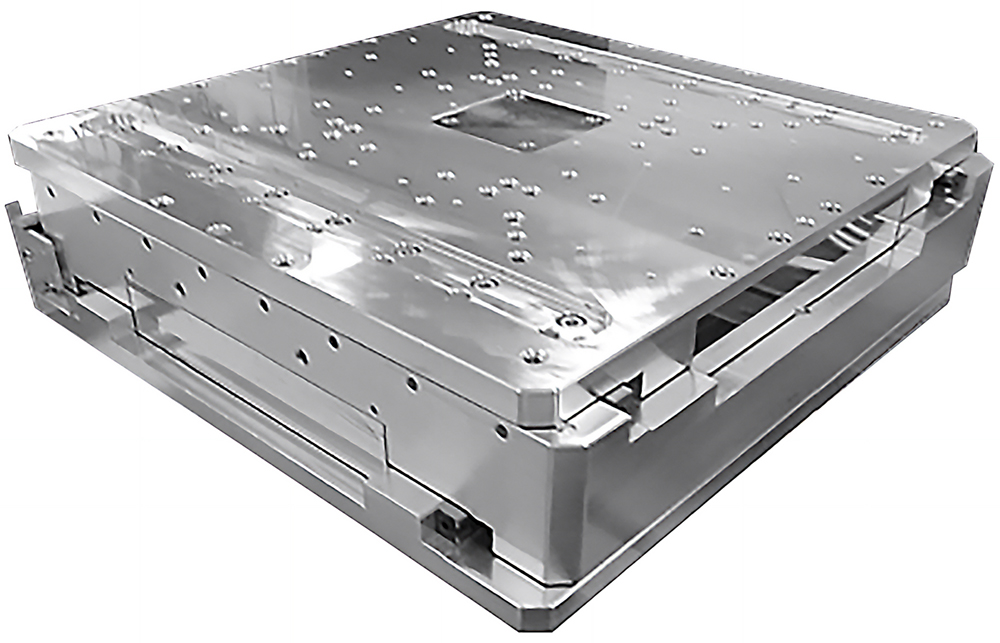

Aerotech has three major application fields. First, the semiconductor industry, where its motion control solutions enhance the efficiency and accuracy of manufacturing processes. Next is electronics manufacturing for electronic components production. Third is the medical devices, where Aerotech’s solutions enable medical and laboratory equipment manufacturers to enhance throughput quality.

In this interview with AEI, Teo charted the landscape of high-precision motion control technologies and their crucial role across application fields, particularly in semiconductor fabrication and packaging.

AEI: Can you discuss the trends driving high-precision motion control?

Teo: A pivotal trend is the demand for smaller, more compact motion control systems. This surge in demand results from increasingly sophisticated and space-constrained applications, leading to the development of seamlessly integrated miniature components like motors, drives, and sensors.

In addition, the integration of artificial intelligence and machine learning is another major driver in high-precision motion control. These technologies enable the development of intelligent motion control systems that adapt to changing parameters, enhancing accuracy, efficiency, and safety by optimizing performance and learning from real-time data. This reflects a transformative shift towards smart and adaptive motion control solutions.

Lastly, the advent of Industry 4.0 and the widespread adoption of IoT have ushered in a new era for high-precision motion control. Accordingly, this trend creates remote monitoring, diagnostics, and predictive maintenance opportunities. Industry 4.0 and IoT connectivity facilitate real-time insights. Thus, enabling proactive measures to ensure optimal performance, reduce downtime, and enhance the overall reliability of motion control systems.

AEI: How about the specific trends in the semiconductor and microelectronics industry?

Teo: Continued node miniaturization is a cornerstone trend in the semiconductor sector, demanding precision in manufacturing processes. Aerotech leads in providing motion control solutions crucial for fabricating and validating microscopic circuitry on modern chips.

Furthermore, another significant trend involves the shift to advanced packaging techniques or novel packaging methods to enhance chip performance and functionality.

The deployment of Photonic Integrated Circuits (PICs), facilitating high-speed, energy-efficient data transfer, is another pivotal industry development. The manufacturing and testing of PICs demand precision motion control, crucial for accurate optical component alignment.

AEI: What are the critical elements necessary to optimally serve the automation demands of this industry?

Teo: Central to our commitment is the recognition that the industry demands high precision, throughput, yield, and accuracy. Thus, Aerotech aligns its solutions with these prerequisites. In addition, understanding the critical role these play in ensuring our customers’ success.

Scalability is a key principle in our approach. Our solutions are designed to be inherently scalable, facilitating seamless transitions from research applications to full-fledged production. This flexibility supports the seamless transition from applications in laboratories to large-scale fabrication. Hence, offering a cost-effective and efficient path for clients.

Our Automation1 controller platform encapsulates all essential elements for high-precision automation. Thus, meeting the most demanding criteria that our clients may have and reflecting our commitment to providing a unified solution across diverse applications.

AEI: How does the global supply chain issue impacted Aerotech and what measures are you taking to address this challenge?

Teo: In recent years, global supply chain challenges have significantly impacted various industries, prompting Aerotech to take decisive steps to mitigate these effects. One primary strategy involves exploring and establishing alternative sources for crucial components, fostering resilience, and reducing our vulnerability to single-supplier reliance.

This proactive approach ensures a robust supply chain, enhancing our ability to navigate disruptions effectively. Nonetheless, Aerotech’s continuous efforts to diversify our sources and to closely monitor the situation will position us to respond swiftly to changes.

Moreover, by maintaining flexibility and adaptability in our supply chain strategies, Aerotech aims to navigate the current challenges and contribute to a more stable and resilient global supply network in the long run.

AEI: Can you share Aerotech’s business outlook for the coming year?

Teo: In the coming year, Aerotech expects positive business performance driven by key industry trends, including an increase in the integration of AI and 5G technologies that will fuel demand for high-precision motion control solutions.

Controlled inflation is anticipated to boost consumer purchasing behavior. Particularly, in consumer electronics, computing, and communication, generating greater demand and positioning Aerotech for growth. To capitalize on these dynamics, the company is focusing on optimizing our processes, enhancing our supply chain resilience, and increasing our investment in research and development to stay ahead in technological advancements. Aerotech is dedicated to maintaining its agility and adaptability in order to navigate changing market dynamics and deliver innovative solutions to meet the evolving needs of its clientele.