ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yamaha’s New Software to Lift SMT Efficiency

Yamaha Robotics SMT Section has introduced enhanced software tools to accelerate new product introduction (NPI) using YSUP-PG, the program generator for the company’s surface-mounters and inspection systems.

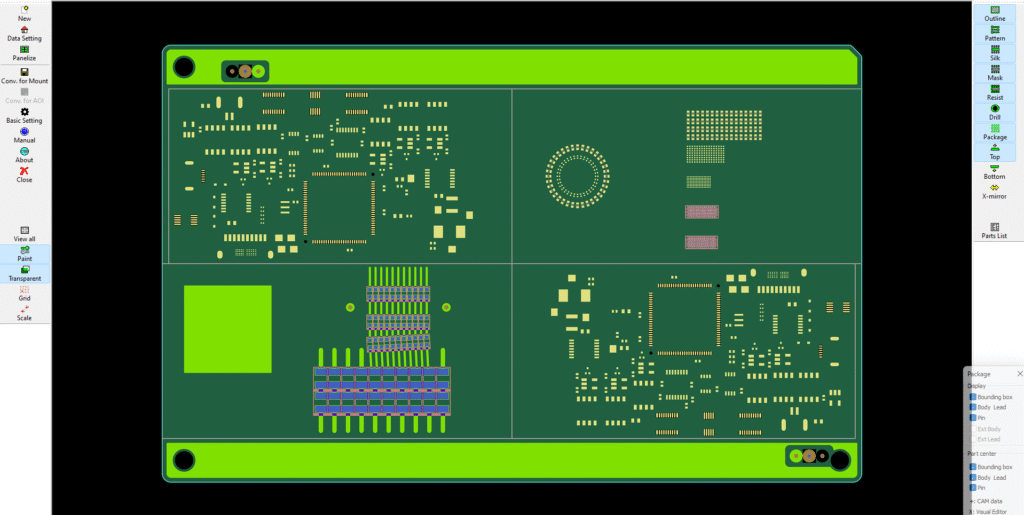

With an enhanced user interface and new automated skills, the latest version of YSUP-PG accelerates data conversion from popular EDA file types such as ODB++ when generating mounter and inspection programs.

The upgraded features take over routine procedures, provide clickable at-a-glance task lists, and update component-placement images in real-time to help manage work items and monitor progress. Leveraging this assistance, users can apply their expertise to ensure the integrity of incoming data and quickly generate high-quality programs.

Leverages Advanced Compute, Data Analytics

Shuichi Imai, Sales General Manager for Europe, Yamaha Robotics SMT Section said the SMT line is where each new product crosses from the digital world until it becomes real. “Historically, merging these information sources into a buildable project has been time consuming and laborious…By leveraging advanced computing principles and data analytics, the latest YSUP-PG now makes programming faster, easier, and more efficient than ever for Yamaha customers.”

Also new, YSUP-PG generates AOI libraries directly from CAD information, ensuring greater efficiency and faster NPI by enabling teams to develop the mounter and AOI programs concurrently.

In addition, YSUP-PG includes enhanced gerber image and CAM conversion tools that generate highly accurate simulated board images to further ease AOI programming. The gerber image tool has built-in image compositing capabilities that automatically calculate how to construct the image from the descriptions of different PCB layers.

Leveraging accurate knowledge of the board geometry gained from combining the gerber and CAD data, YSUP-PG calculates push-up pin positions digitally. The calculated positions save manual fine-tuning, traditionally done by referring to a physical assembly, reducing user workload and helping accelerate NPI.

The images additionally enable accurate desktop trial mounting, letting users verify component coordinates, polarity, and angle in advance to save building test assemblies and ensure full production can begin straightaway.

15 October 2025