ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Japan Unix Develops Laser Irradiation Technology

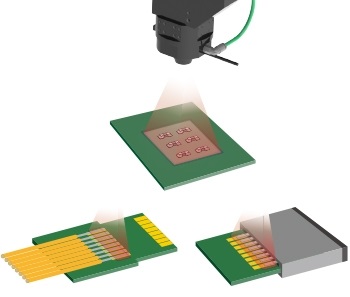

Japan Unix Co., Ltd. has developed Area Laser, a laser irradiation technology for laser soldering robots.

The energy within the laser irradiation range is uniform. The Area Laser can irradiate a beam with a shape other than a circle (square and rectangle). This feature has enabled the use of laser soldering robots in the surface-mounting technology (SMT) process.

Business Lines

The company manufactures and sells various soldering robots. Its portfolio includes the semiconductor laser type that can perform soldering without contact, ultrasonic type, and trowel type. Manufacturers of automotive boards, digital devices, medical devices, industrial devices worldwide use its products. Japan Unix also offers software, like UNIX-DF, a network-compatible soldering robot supporting internet of things (IoT) and Soldering Manager.

Laser Irradiation Technology

Multi-Phi

The company has already developed the Multi-Phi laser irradiation technology for through-hole terminals. Using this technology allows changes in the outer diameter of the laser beam while it remains circular. Also, the energy can be strongly applied to the center.

Kentaro Kono, General Manager of Japan Unix, says “Multi-Phi is a technology developed for through-hole terminals. The Area Laser can irradiate a beam with uniform energy within the range and shape other than a circle (square and rectangle). It has become possible to support production methods suitable for surface mounting. In addition, CO2 reduction is required as a countermeasure against global warming in recent years. There is an urgent need for such countermeasures in the field of mounting.”

Area Laser

“Whenever we introduce the Area Laser technology to customers, we realize they are keenly interested in reducing CO2 in the mounting process. The Area Laser is likely to be less productive than reflow ovens, but it realizes low CO2 emissions. The company widely proposes the Area Laser as a low environmental load mounting technology suitable for the sustainable era,” he continues.

Laser Solder for Area Laser Technology

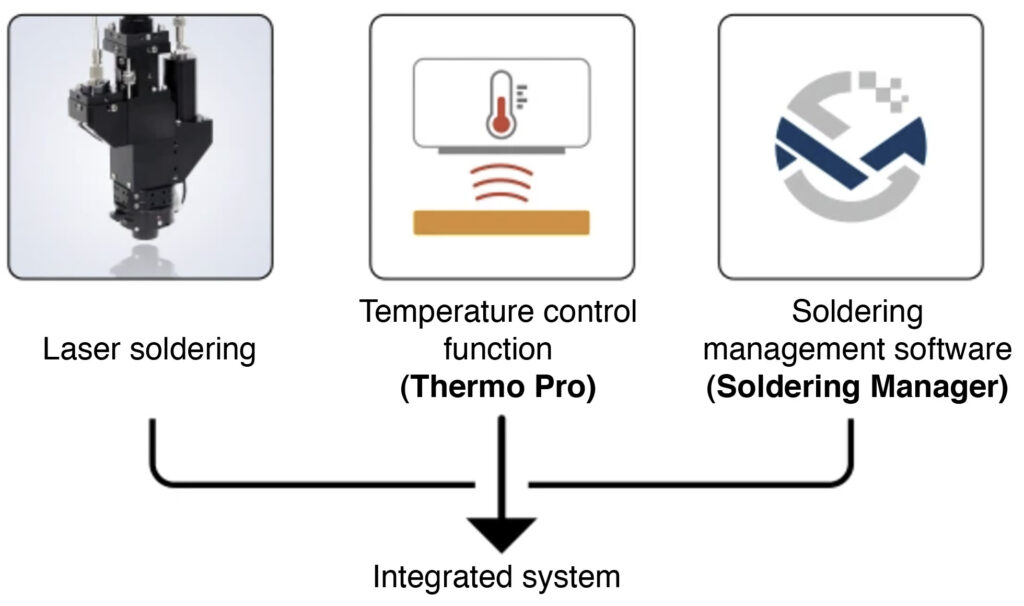

The company has commercialized ULD-02, a new laser soldering unit that realizes the area laser technology. ULD-02 has achieved high level of soldering process control by optimizing the laser shape. It has also enhanced the traceability and the temperature measurement and control function. The Multi-Phi function can also be used as an option by replacing the functional unit.

Installing Thermo Pro enables management and control of the temperature during soldering aside from conventional control items in laser soldering.

By using the ULD-02 PC software Soldering Manager Pro, monitoring each soldering status in real time and saving it to the PC is possible. A video storage function using a coaxial camera can also be installed, enabling full remote operation of the production control. Users can edit conditions from the outside by communicating with the data link. They can also control the solder with tar by using the ULD-02 controller.

The company will promote Area Laser as the most optimal manufacturing method for handling a wide variety of small lots. It is also ideal for board mounting of small devices such as electronic devices, mobiles, wearables, light vehicles, and IoT.