ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Mitsubishi’s New Tool Enhances Factory Operations

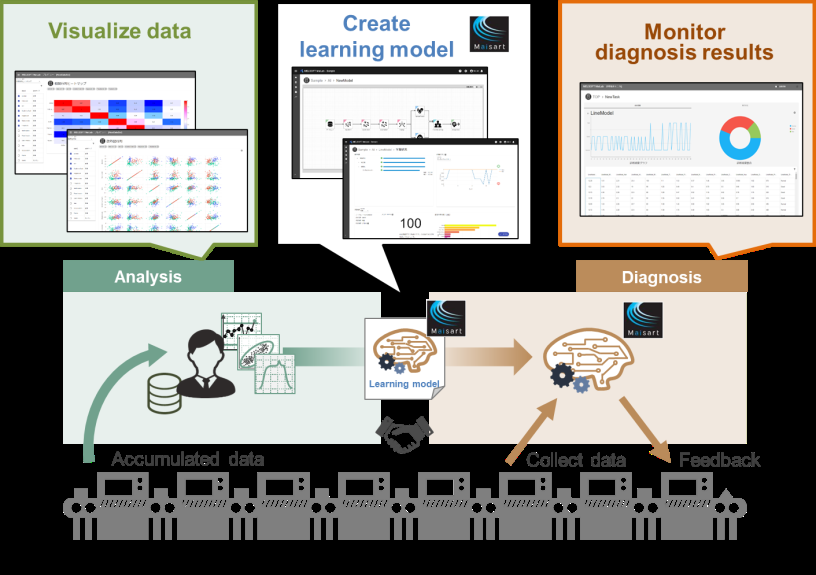

Mitsubishi Electric Corporation has introduced MELSOFT MaiLab, a data-science tool that uses the company’s Maisart® AI technology. Particularly, this enables non-specialists to analyze and diagnose factory data skillfully and easily. This includes current and pressure values for intuitive, high-level management of production operations.

Recently, manufacturers are increasing the use of various data from the factory floor to further enhance productivity, which is stimulating needs for data collection and visualization as well as advanced analysis and diagnosis.

On the other hand, several factory operations like production management and equipment maintenance still require human workers. Hence, making tasks such as equipment adjustments and consumables-replacement timing, dependent on the experience of skilled workers. The lack of such skilled workers, however, is becoming a critical issue for manufacturers when they try to promote advanced data analysis and diagnosis.

Streamlines Production Processes

Mitsubishi Electric’s MELSOFT MaiLab tool utilizes AI technologies like deep learning and other statistical methods to automatically learn how skilled workers evaluate operations, which enable this tool to be handled very easily without requiring any special knowledge of factory operations. Thereafter, the automatic learning process, the analysis and diagnosis results will feedback from MELSOFT MaiLab. This is for adjusting equipment parameters, which helps manufacturers automatically improve their operations and further increase productivity. Going forward, the tool’s functionality and AI technologies incorporated will be updated in response to the growing needs of manufacturers.

In addition, the launch of MELSOFT MaiLab is part of Mitsubishi Electric’s ongoing effort to support customers with digital technologies that can help streamline production processes and reduce engineering costs. Through such activities, Mitsubishi Electric aims to transform into a “circular digital-engineering company” focused on solving a wide range of social issues together with its customers.

Key Features

1) Automated learning process allows non-specialists to analyze and diagnose production data for improved productivity.

Particularly, it features automated machine learning (AutoML), an AI automated-learning function, realizes data analysis and diagnosis and gives automatic feedback to equipment for improved productivity without requiring users to possess data-analysis expertise. In addition, the AI generates learning models to help inexperienced workers perform equipment adjustments at similar levels as specialists. Here, it is possible through monitoring factory data and how skilled workers evaluate operations to adjust the parameters in production equipment.

2) Supports intuitive operation and easy analysis/diagnostics with rich graphic displays

Meanwhile, various graphs like correlation matrix heat maps and scatter plot matrix are available to visualize factory data, supporting intuitive operation and easy data analysis. Furthermore, results of the AI diagnosis can be shown as bar graphs and pie charts for intuitive understanding. It is possible to use tablets to check production status remotely.