ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Hitachi Metals' Magnetic Slot Wedge for Motors Supports Decarbonization

Hitachi Metals, Ltd. had developed new magnetic slot wedges for motors in an effort to increase their efficiency. It was achieved through the advancement of its original powder metallurgy technology accumulated over many years.

Mainly, Hitachi Metals will strive to achieve lower loss and higher efficiency of motors. It will leverage the high magnetic permeability and reliability of the newly developed product with a view toward aiding the reduction of power consumption and carbon dioxide (CO2) emissions.

Main Source of Power Consumption

Induction motors are powered by the electromagnetic force of an alternating current. They are extensively used for industrial applications such as pumps and compressors, and in rail rolling stock, among others. Nowadays, individual countries are working to increase the efficiency of induction motors through the Top Runner Program*1.

It is said that motors are responsible for 40 percent of global power consumption. Thus, to reduce power consumption and CO2 emissions from power generation, increasing the efficiency of motors is a key issue. There are many different efforts towards this goal.

Increasing Efficiency of Induction Motors

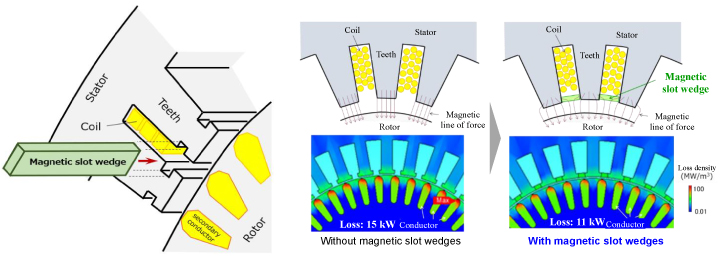

One of the efforts that is drawing attention is focused on magnetic slot wedges. Magnetic slot wedges increase efficiency after installation without changing the structure or size of the motor. Generally, slot wedges for motors prevent coils in core slots from falling off. Slot wedges made of magnetic materials attract magnetic flux*2 and increase energy efficiency (Figure 1).

→Compared with the state without wedges, loss (shown in red) is reduced.

However, existing magnetic slot wedges*3 contain iron powder dispersed in resins. This results in poor magnetic permeability*4 and failure to sufficiently improve motor efficiency. In addition, the heat resistance of these magnetic slot wedges is so poor that they were not appropriate for high-temperature applications. For these reasons, magnetic slot wedges for motors must feature high strength, magnetic permeability, and heat resistance to withstand severe conditions inside motors.

High-performance Magnetic Slot Wedges

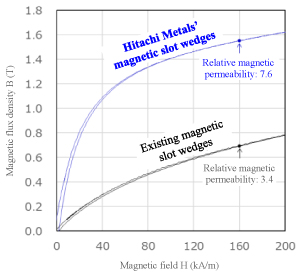

→Magnetic permeability nearly double that of existing wedges.

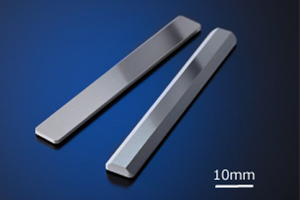

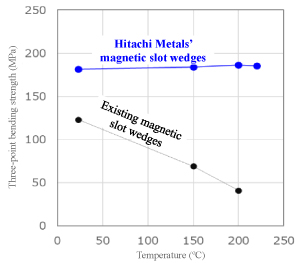

Hitachi Metals has recently developed a new type of magnetic slot wedge that does not contain any resin. These magnetic slot wedges are realized using a new technology that bonds magnetic particles. Particularly, this new technology increases the density of magnetic particles. Also, it achieves high magnetic permeability that is about double the level of existing magnetic slot wedges (Figure 2). The high density leads to high strength that is around 1.5 times the strength of existing ones. Without containing resin, Hitachi Metals’ 10mm magnetic slot wedges exhibit outstanding heat resistance. This enables the wedges to maintain their strength in high temperature conditions (Figure 3).

→Strength is higher than existing wedges and it does not fall even at high temperatures.

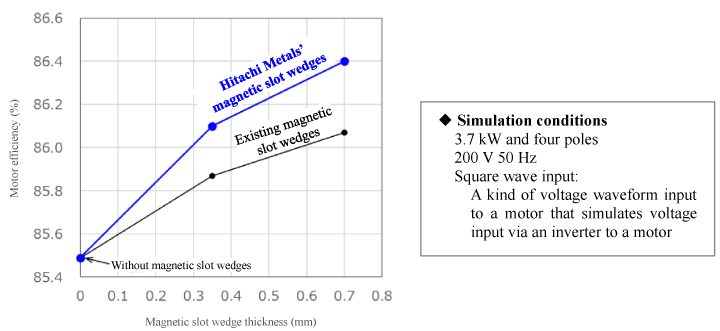

The new magnetic slot wedges suppress eddy-current loss*5 that occurs in them because their electric resistance is higher than existing ones. In addition, they are expected to help improve motor cooling efficiency since they have higher thermal conductivity than existing ones. A computer simulation suggests that the new magnetic slot wedges sized 0.5mm or larger increases the efficiency of the general 3.7-kW four-pole motors used in pumps, compressors, and other devices by around 1 percent compared with motors without magnetic slot wedges or about 0.5 percent compared with motors with existing magnetic slot wedges (Figure 4).

Hitachi Metals’ magnetic slot wedges are characterized by their high magnetic permeability, strength, and heat resistance. Therefore, they can be used in motors in different sizes and for different applications where magnetic slot wedges were not conventionally used.

→Efficiency is higher than the motor with existing wedges.

On the occasion of this development, Hitachi Metals will promote the products as a solution for increasing motor efficiency to global customers engaging in motor development. As a high-performance materials company that supports a sustainable society, the company will endeavor to achieve carbon neutrality.

Endnotes:

*1 Top Runner Program: A program launched to ensure both consumer satisfaction and energy efficiency measures in a manner based on the method by which a goal of exceeding the level of the most energy efficient device is set when the standard value is formulated. In Japan, the program is used for automobiles and home electric appliances, for example.

*2 Magnetic flux: A group of magnetic lines of force that represent the force applied at different points in the magnetic field. Electric field intensity and direction at a particular point are represented as a bunch of lines.

*3 Existing magnetic slot wedges: The specifications had been researched, investigated, and evaluated by Hitachi Metals Ltd.

*4 Magnetic permeability: An indicator of how easily the magnetic flux passes through a magnetic material This news release uses values calculated by dividing the magnetic flux density at a magnetic field of 160 kA/m by the magnetic field.*5 Eddy-current loss: Loss resulting from heating due to loops of electric current inside a metal or other substance with low electric resistance after an alternating current magnetic field is applied.*6 InnoTrans: The world’s largest international trade show specializing in railway technologies, which is held in Berlin, Germany every two years (in even calendar years).

URL: https://www.innotrans.de/en/