ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Construction Harnesses Benefits of Digital Technology

Threats of labor shortage in the construction industry have spurred opportunities to tap digital transformation along with IT companies. The industry is now employing latest innovations such as three-dimensional (3D) surveying using smartphones and artificial intelligence (AI)-equipped anomaly detection.

Cuts Construction Time

Chikashi Shike, Executive Officer and in charge of DX in Komatsu Ltd. said, “Compared with other industries, construction offers more solutions to significant issues if we employ digital technology. Using the cloud, for example, high-quality services can be uniformly provided.”

Komatsu has introduced the system of Amazon Web Services (AWS), handling cloud services, and is promoting its own smart construction business. The use of DX can visually display in 3D the topographical data of the ground surface as surveyed by a drone and other construction data. This will lead to the higher efficiency and will shorten large-scale construction.

For example, by superimposing the topographical data with the 3D data of the completed design, a system can create the travel route of dump trucks transporting earth and sand. This can lead to higher efficiency and can shorten construction time.

In Times of Disasters, Too

Software developer OPTiM Corporation and construction company Matsuo Construction Co., Ltd. has developed an application that enables high-precision 3D surveying using laser light. It employs a smartphone or a tablet equipped with a LiDAR sensor in detecting distance to an object and its position.

It supports the use at small-scale construction sites where use of drones is difficult. The technology also reduces survey time to 60 percent. Furthermore, the survey is also possibly by employing only one person, solving issue of shortage of engineers at the site.

In July, the Disaster Prevention Communication Training of the Ministry of Land, Infrastructure, Transport and Tourism adopted the 3D surveying technology. This does not only reduce survey costs but also survey time, making the technology a viable application in disaster sites.

Suits Cable Installations

DX also advances in the inspection and maintenance work. The deployment of 5th generation communications standards has increased installation demand for optical fibers. NEC Corporation has started to provide a new system that detects abnormalities in these installations, analyzing vibrations detected with the use of AI. The information provides accurate location of cables that need repair work.

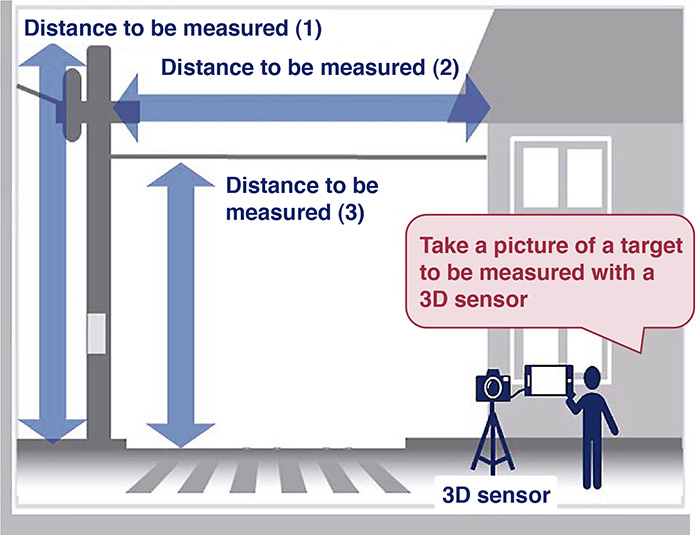

NEC Communication Systems, Ltd. has developed a separation measurement technology that can determine the distance between utility poles and electric wires based on images taken with 3D sensors and tablets. It can measure the distance from a remote location by applying the space recognition technology of the 3D sensor.

It will improve the safety of equipment inspection work for utility poles and electric wires performed by electric power and railway companies. NEC plans to make the technology for commercial release later this year.