ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Cross Roller Bearings Innovate Industrial Robots

Manufacturers of linear motion guides have been expanding their lineups of new cross roller bearings (cross roller rings) for robots. Simultaneously, they are also strengthening their production systems to meet the expansion of the robot market.

In Japan, declining birthrate and an aging population have advanced. For that reason, the manufacturing industry have introduced robots to cope with serious labor shortages, which has been building up.

Furthermore, the onset of the COVID-19 pandemic has paved the way for the use of robots to minimize contact-less services. Thus, the market of industrial robots and service robots has been expanding.

Critical Components of Robots

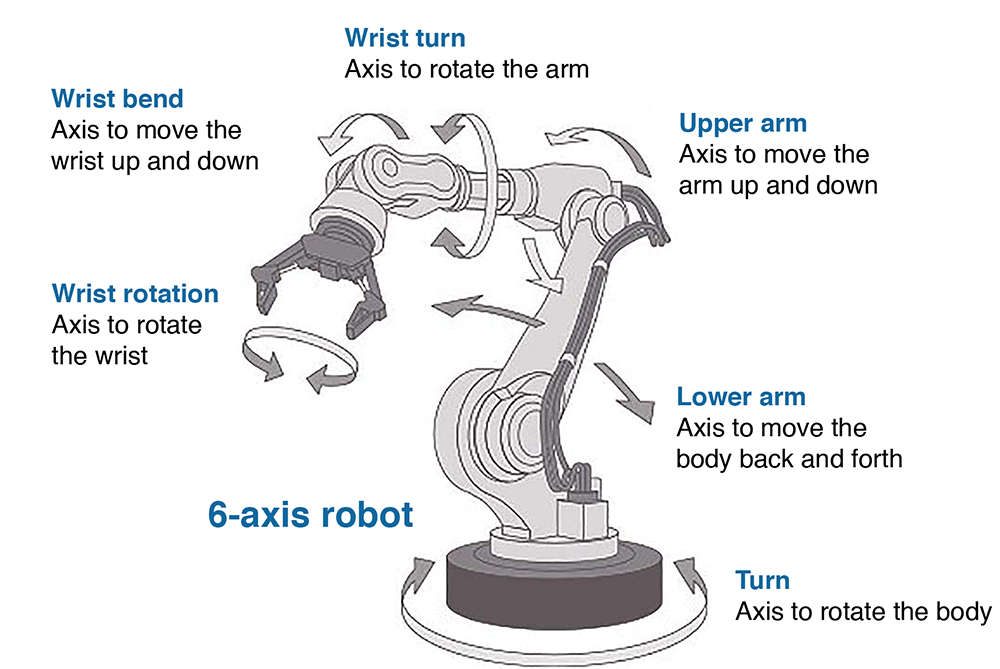

To meet expanding demands, manufacturers of linear motion guides have been expanding their lineups of cross roller rings. To illustrate, cross roller rings are one of the important element components of robots. They are critical to enabling the turning parts of a robot.

Earlier in April, THK Co., Ltd. the RB-H, RE-H and RU-H high rigidity Series models of cross roller rings with dimensional compatibility with existing products. Following these, the company released in August the RBU model of cross roller ring. It features an integrated inner/outer ring with stable structure and contributes to significant reduction of time required for mounting.

The RBU model has cylindrical rollers alternately and orthogonally arranged via spacer retainers between the inner ring and the outer ring. Hence, it can bear loads in every direction, namely radial load, axial load, and moment load. In addition, it can obtain high rotation accuracy.

The RBU model is available in a total of 24 model numbers with the axis diameter range of φ20 to 190mm. It has dimensional compatibility with the existing model number RB model. Thus, allowing easy replacement to the RBU model without design change.

NIPPON THOMPSON CO., LTD. has expanded its lineup of cross roller bearings, adding the CRBTF ultrathin cross roller bearing with mounting holes.

Meets Compact, High Rigidity Requirements

The company’s cross roller bearings feature compact structure with rollers orthogonally arranged between the inner and outer rings. Most importantly, the orthogonally arranged rollers enable a single cross roller bearing to simultaneously receive complex loads from every direction. Their main application is in the turning part of industrial robots for which compactness, high rigidity, and rotation accuracy are important.

CRBTF has been developed by forming mounting holes in the inner and outer rings. CRBTF is the thinnest and lightest of the company’s cross roller bearing series. Moreover, it allows direct mounting to mating components using mounting holes. Thereby, contributing to making the turning section of equipment compact and lightweight.

The company’s proprietary knowhow to manufacture ultrasmall bearings has achieved the thin bearing width of 5mm.

NIPPON THOMPSON has been ramping up production at its plant in Vietnam to meet the increasing demand for cross roller bearings.

Meanwhile, among NSK Ltd.’s lineup of precision bearings, the cross roller bearings are the robust series. These are the high-function bearings and the N Series that meet market needs.

A single bearing of the N Series bears radial load, axial load and moment load. In addition, it suits use in the joint sections of industrial robots. Thus, application of pre-load further enhances its rigidity.