ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

TDK High-speed TMR Front-end IC Speeds ups EV Motor

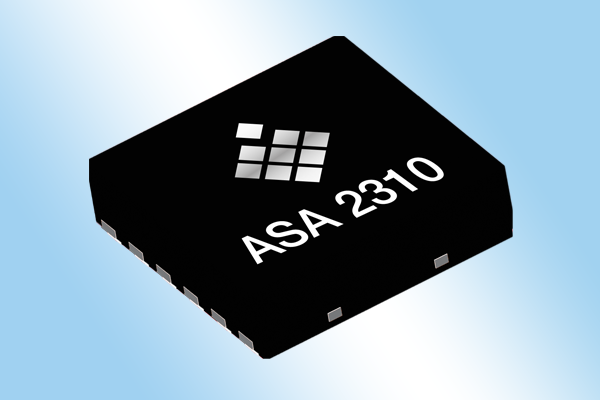

TDK Corporation complements the existing tunnel magnetoresistance (TMR) sensor portfolio with the new ASA 2310 Micronas signal-conditioning IC for high-speed automotive and industrial electric motor applications. ASA 2310 is a low-drift, low-noise, customer-programmable TMR front-end IC with differential or single-ended SIN/COS inputs and analog outputs. Samples of ASA 2310 are now available. The production is planned to start at the end of 2023.

Interface for High-Precision Analog TMR Sensor

Specifically, the ASA 2310 is designed to interface the high-precision analog TMR sensors of the TAS family. The sensors are powered and monitored by ASA 2310. They detect magnetic-field direction in x-y plane. Also, they provide a SIN/COS analog voltage output, which is used as input for the ASA 2310. The sensor interface and signal conditioning of the ASA 2310 are optimized for the TMR-Bridge signals.

Major characteristics like gain, offset, (absolute) 0-angle, and orthogonality can be adjusted using the integrated signal path by programming the non-volatile memory of the ASA 2310. The different coarse gain settings ensure that the device can support various TMR full- and half-bridges from TDK. The amplified single or differential ended output signals of the ASA 2310 can be used to calculate the rotation angle of a magnet with very high accuracy by an external A/D-converter and an ECU.

Offers Optimized Range

New rotor position sensing solutions based on the ASA 2310 offer a high resolution and accurate position measurement at very high rotation speeds of up to 650,000 rpm. This enables high-speed motors to maximize torque and increase efficiency, which is essential for hybrid and electric vehicles to obtain maximum range. In addition, the sensor system configuration works independently of the motor pole pair number and therefore does not require complex hardware changes, a major advantage over inductive resolver technologies. This gives more flexibility in the development of the hybrid and electric powertrains of the future.

With its overvoltage and reverse polarity protection (±18V), the ASA 2310 features excellent robustness against electrical challenges. Compared to off-the-shelf amplifier ICs, the ASA 2310 is more appropriate for safety-critical applications. The signal-conditioning IC, which simplifies the external circuitry, resulting in a low FIT rate makes this possible. Moreover, the total system size, BOM, and assembly process costs are reduced.

Standards-Compliant

Specially, this product is defined as SEooC (Safety Element out of Context) ASIL B ready according to ISO 26262. To enable the most efficient failure localization and elimination, the ASA 2310 provides a single-point fault metric (SPFM) of more than 97%. This level exceeds even the standard requirements of an ASIL B classification. If ASIL decomposition is applied on the system level, the IC can be integrated in systems up to ASIL D.

The ASA 2310 features various integrated safety monitoring of the IC itself and the external TMR-bridges. Additionally, it features an optional and unique fluxless self-test. This feature allows the system to test the full signal path inside the device before the ordinary operation starts. In an application setup, the test can be used to check integrity of the whole signal path including wiring, external output capacitors and ECU. Finally, the variety of safety monitoring helps to increase diagnostic coverage and simplify the external safety supervision on the ECU side.

High-Performance IC

“The ASA 2310 is a high-performance IC that extends the functionalities of a very precise analog TMR sensor and reduces the influence of noise and parasitic components caused by remote application setups where the sensor module is separate from the ECU and connected by a long wire-harness,” says Frederik Berstecher, Product Marketing Manager for “Fast Hall & TMR” at TDK-Micronas.

“When combining it with TDK’s TMR TAS sensor family, customers can commercially scale their application setups depending on accuracy, EMC or functional safety requirements since the ASA 2310 can operate up to four TMR half-bridge sensors at the same time. Thus, rotor position sensor solutions based on the ASA 2310 can be used for a wide variety of safety-critical applications like power steering, brake boosters, or traction motors.”*

While the TMR TAS sensors are available in a wide package portfolio (single-die, dual-die), the ASA 2310 signal-conditioning IC is offered in a very compact 3×3mm DFN12 SMD package. A reference evaluation board consisting of magnet design and sensor + signal conditioning chipset is available on request from TDK.