ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Henkel High Thermal Paste Works with Bare Silicon Die

Henkel introduces LOCTITE® ABLESTIK® ABP 8068TD high thermal die attach paste. The new product line of pressure-less sintering die attach material is suitable for applications where no die back-side metallization (BSM) is required, although can be used if desired.

The adaptability of the material gives semiconductor companies a high thermal conductivity die attach option for bare silicon (Si) die integration. Particularly, this new material is well-suited for high power applications.

Henkel’s Semiconductor Packaging Market Strategy Manager, Raj Peddi, explains LOCTITE ABLESTIK ABP 8068TD’s importance for the power sector. He also highlights the application flexibility it enables. “This material allows packaging specialists to satisfy the requirement for high heat dissipation in applications where bare silicon die are used, particularly in situations where back-side metallization processes are cost- or process-prohibitive,” he says.

“Because the material is compatible with different dies – whether metallized or not – it provides more design and manufacturing opportunities for OSATs and power device developers.”

Addressed Challenge of High-Lead Solder

Henkel developed and launched its pressure-less sintering die attach paste platform in 2017. As a result, it was able to address challenges associated with the use of conventional high-lead solder. Also, it dealt with the thermal conductivity limitations of traditional die attach materials and the processing complexities of pure silver sintering products.

The new die attach material is applied and processed in the same way as standard die attach adhesives. Thus, the unique chemistry of Henkel’s pressure-less sintering materials allows the formation of an interpenetrating network of silver (Ag) and resin. In turn, it enables excellent interface contact, high thermal conductivity, and good thermal cycling reliability.

Main Features of LOCTITE ABLESTIK ABP 8068TD

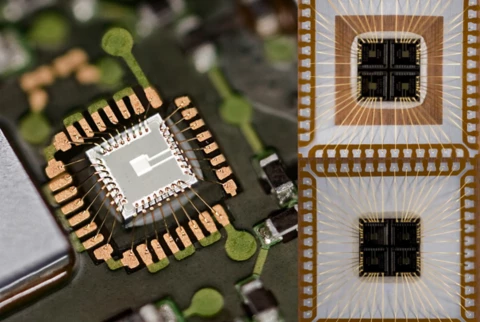

Mainly, LOCTITE ABLESTIK ABP 8068TD extends the benefits of pressure-less sintering to a wider variety of power packages using different types of die and lead frame finishes. The material features bulk thermal conductivity of 50W/m-K. Also, it was evaluated across several standard testing regimens with bare Si die and Ag-metallized die of various dimensions, up to 5.0×5.0mm; as well as on copper (Cu), Ag and pre-plated (PPF) lead frame finishes.

Additionally, consistent with other Henkel pressure-less sintering adhesives, LOCTITE ABLESTIK ABP 8068TD exhibited excellent workability, good dispensing performance, no resin bleed out on any of the tested lead frames, strong adhesion to all surfaces, and long open (2.0 × 2.0mm die @ 2 hrs.) and stage times (2.0 × 2.0mm die @ 24 hrs.). Also, LOCTITE ABLESTIK ABP 8068TD features notable reliability. Specifically, it achieves MSL 3 on most tested die finish/lead frame combinations and MSL 1 for several Ag-BSM and bare Si die/lead frame pairings.

“Already proven in volume production, LOCTITE ABLESTIK ABP 8068TD delivers another high-thermal, package-level solution for devices integrating bare Si and/or metallized die, including QFNs, SOTs, and LGAs, among others,” reveals Peddi. “This is an important development for the power package sector.”