ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Smart Factory Systems Cap Henkel’s New Korea Plant

Henkel AG & Co. KGaA, through its Korea subsidiary, has announced the completion of its Songdo Plant. Particularly, the state-of-the-art facility lies in the Songdo High-Tech Industrial Cluster in Korea’s Incheon. Most importantly, the company said the facility will become its Asia Pacific production hub for high-impact electronics solutions of the Adhesive Technologies business unit.

Henkel Korea signed a memorandum of understanding (MOU) with the Incheon Free Economic Zone Authority in April 2019 for the project and started construction work in the same year. With an investment of approximately €35 million, this is the largest single investment in the company´s history in Korea.

The company held a building dedication ceremony attended by ranking city government officials led by Incheon City Mayor Jeong-bok Yoo. Also present were Chargé d’Affaires of German Emabssy Peter Winkler, the Chairwoman of the Korean-German Chamber of Commerce and Industry Hyun-nam Park, Executive Vice President Henkel Adhesive Technologies Jan-Dirk Auris, and President of Henkel Asia-Pacific Mark Dorn.

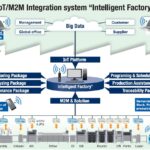

Advanced Smart Factory System

With a total floor area of 10,144 square meters and in a two-story building, the Songdo Plant implements an advanced smart factory system (SFS). Most importantly, this will enhance process monitoring, data collection, and troubleshooting. After undergoing trial production and quality verification since last year, the plant began production in the second half 2022.

“The opening of our state-of-the-art Songdo plant is a milestone for our Adhesive Technologies business to further expand our capabilities to create value for our broad global customer base in electronics with high-impact solutions for major industry trends such as connectivity and sustainability,” said Jan-Dirk Auris, Executive Vice President Henkel Adhesive Technologies.

“In addition, the new facility demonstrates our ambition to further drive the implementation of Industry 4.0 across our production network while at the same time significantly reducing our environmental footprint.”

For IC Packaging, Components, Device Assembly

The design of Henkel’s Songdo Plant is to produce adhesive solutions for semiconductor packaging, electronic components, and device assembly. The high-performing and tailor-made products enable customers to develop advanced technologies for electric vehicles, electronic devices, and electronic materials as well as to increase sustainability by reducing CO2 emissions during the entire lifecycle and by improving circularity.

Meanwhihle, the Songdo Plant aims to strengthen the relationship of Henkel Korea with key customers and to drive value creation for them. Thanks to the plant’s proximity to Incheon International Airport, goods can be shipped more quickly to local customers, providing additional benefits including longer product shelf life.

Mark Dorn, President of Henkel Asia-Pacific, commented, “With the completion of the Songdo Plant we see an opportunity for Henkel to meet the technological growth potential of the Asia-Pacific market, including Korea. In addition, the Songdo Plant will serve as one of Henkel’s global production hubs in electronics.”

Designed with a smart factory system, the Songdo Plant delivers world-class production capacity through its improved linkage between process inputs and product performance. In addition, an enhanced production analysis made this possible.

Moreover, plant incorporates a range of sustainability features that make it an eco-friendly production facility, including solar panels, a rainwater recycling system and energy-efficient equipment.