ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Solutions Simplify Smart Machine Development

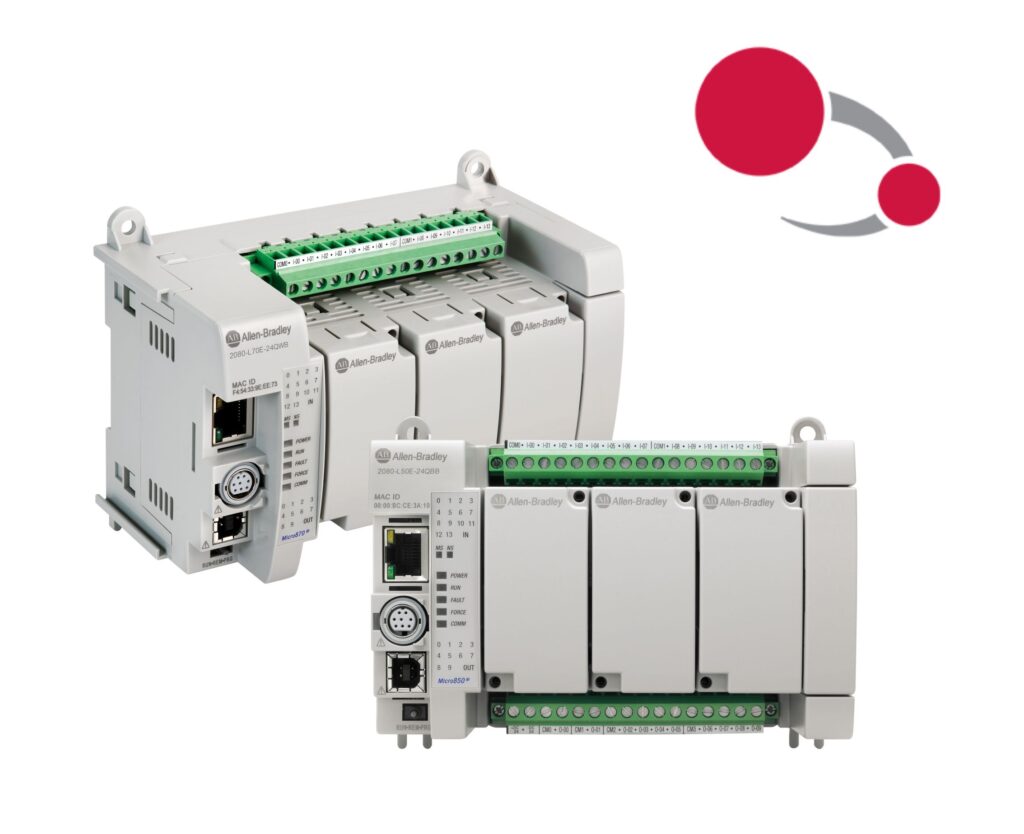

The latest Connected Components Workbench software from Rockwell Automation employs the enhanced Allen‑Bradley Micro850 and Micro870 2080-Lx0E controllers. Hence, enabling machine builders to save engineering time and costs.

Particularly, the improved 2080-Lx0E controllers offer greater connectivity and design efficiency through the new Class 1 implicit messaging capability. It comes with up to eight EtherNet/IP devices support.

Drive Industrial Operations Productivity

The 2080-Lx0E controllers streamline integration of controller to drives. Thus, supporting PowerFlex 520 series and Kinetix 5100 drives over EtherNet/IP with pre-defined tags and pre-developed user-defined function block (UDFB) instructions.

Most importantly, it comes with the easy programming and simpler workflow through a familiar and intuitive design environment. Connected Components Workbench software version 21 is the necessary minimum to support the Class 1 implicit messaging capability in Micro850 and Micro870 2080-Lx0E controllers.

The controller and software enhancements can help drive industrial operations productivity while lowering costs. Users can benefit from a more connected and simplified control system for their automated designs.

Users can minimize programmatic efforts and troubleshooting time, which simplify the development of standalone machines that are built with the Rockwell Automation Micro Control System. The expanded smart capabilities allow users to develop and deploy automation projects faster, which can accelerate time to market and drive business growth.