ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New ASMPT Material Flow App Fits in Smart Factory

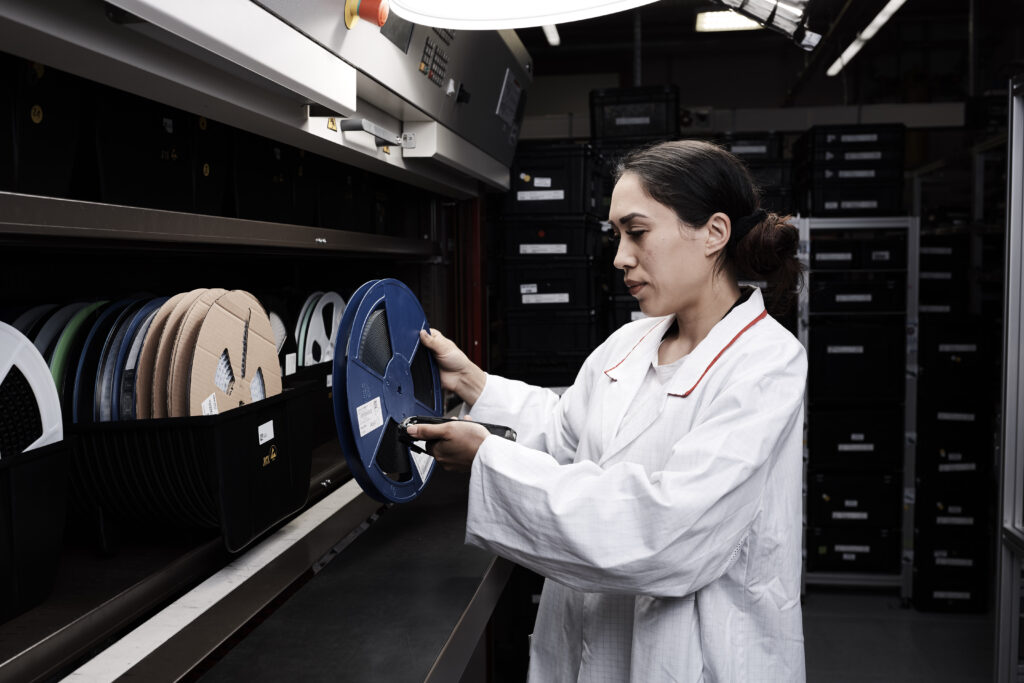

Many processes are already automated and run quite smoothly in modern electronics factories. Meanwhile, the flow of materials is still an exception in many cases, and causes unnecessarily high costs. The initial plans and the actual needs on the line often diverge because of static material requirements planning. This leads to material bottlenecks during production runs. Sometimes, it leads to line stops or to preventive accumulation of space-wasting “emergency stocks” directly at the SMT line. A new application in the WORKS smart shopfloor management suite from market and technology leader ASMPT effectively counteracts this.

WORKS Material Demand Calculation (MDC) dynamically calculates the material requirements for definable time intervals. It takes all incidents into account and continuously adjusts the material requirements. The goal is to always have the right material available at the right time in the right quantity in the right place. It also aims to create maximum transparency in warehouses and around the lines.

Always Up to Date

Many electronics manufacturers still calculate their material requirements in static processes prior to the start of production. They use the results for the entire production cycle. Mainly, too tightly calculated material supplies or unexpected events quickly lead to expensive line downtime. However, if the calculations include overly large buffers, materials may back up at the line. MDC continuously analyses material consumption, cycle times and production progress, and combines this data. In this way, it continuously computes actual material requirements and updates them dynamically.

Since no two factories are alike, the time intervals for the material requirements calculations can be defined individually. MDC thus turns rigid material planning and supply into a time-based and flexible closed-loop control system. It dynamically computes even non-linear material consumption during setups and teardowns. Moreover, it compensates for disturbances such as increased scrap or non-scheduled maintenance cycles.

“This new solution optimally complements our proven applications in the WORKS smart shop floor management suite for the ‘Logistics’ workflow. It enables us to offer our customers unprecedented added value by providing them a basis for their comprehensively automated material supply that is always adapted to current conditions,” says Erwin Beck, Head of Product Management Automation Solutions at ASMPT.

Valuable Space on the Shop Floor

Like unscheduled line downtimes, unnecessary manual activities or travel times between lines and warehouses, wasted space on the shop floor is a disruptive factor that drives up costs. If “emergency stocks” no longer need to be stored at the line, the freed-up space can be used much more effectively for productive machines, special equipment or autonomous transport systems (AIVs).

Seamlessly Integrated into ASMPT’s Open Automation Concept

“Like all the applications in our WORKS suite, the MDC fits seamlessly into our modular Open Automation concept and paves the way for electronics manufacturers to implement their Integrated Smart Factory in stages,” says Erwin Beck.

WORKS Material Demand Calculation completely eliminates manual reordering processes and thus makes an important contribution to the automation and optimization of internal logistics. AIV fleets can now take over the material supply completely and independently, whether according to the milk-run principle, with dedicated deliveries, or according to other criteria. In addition, employees get relief from unnecessary trips. They are notified and instructed automatically and just in time regarding new material supply requests by WORKS Command Center – via smartphone, tablet, or smartwatch.

WORKS Material Demand Calculation in the ‘Facts on Open Automation’ livestream

WORKS Material Demand Calculation is also a topic in the ‘Facts on Open Automation’ livestream on February 22, 2023, in which everything revolves around perfection in material management.

This ASMPT show format offers viewers each month a roughly half-hour English-language livestream around ASMPT’s Open Automation concept with live feeds from international SMT hot-spots, interviews with experts, practical examples from SMT productions, and much more.

More information about the ‘Facts on Open Automation’ series of livestreams is available at https://facts-on-open-automation.smt.asmpt.events/.