ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Fuji Electric Expands Automation, Control System

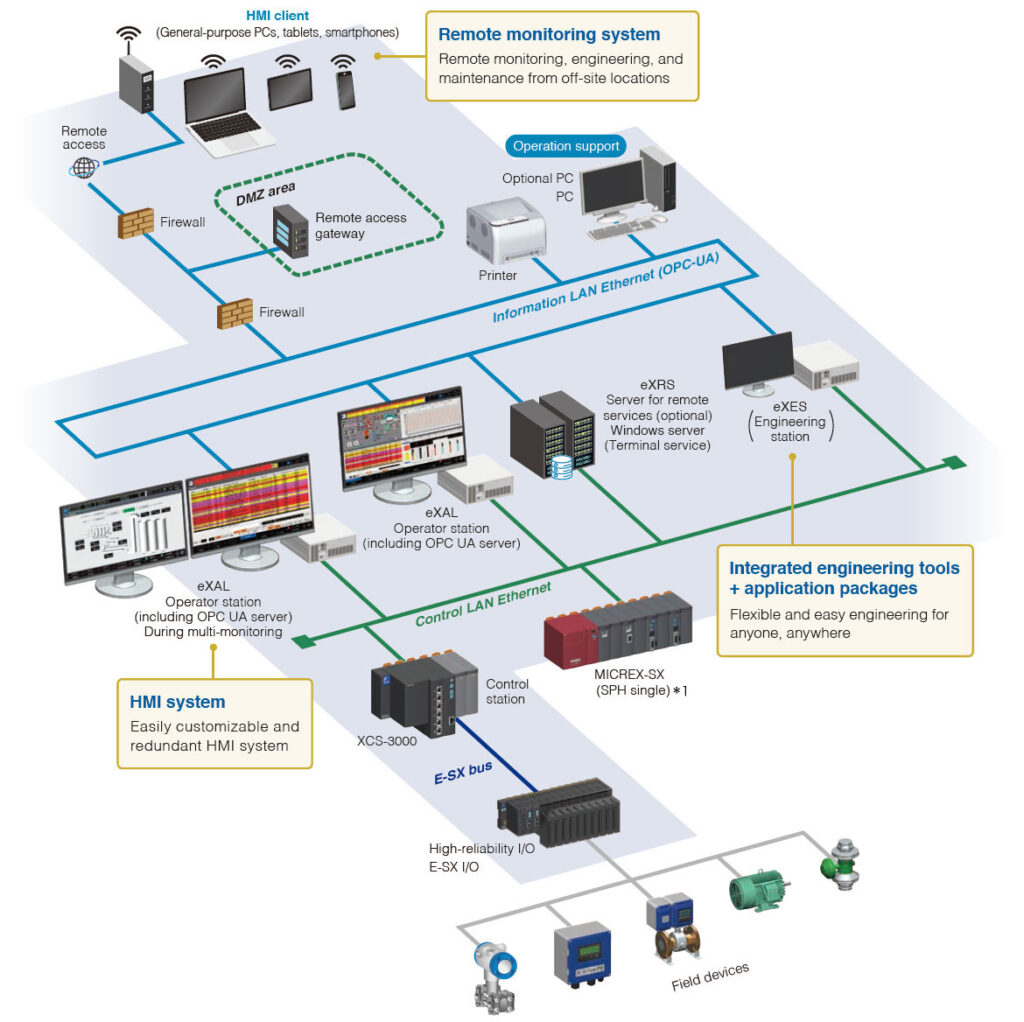

Fuji Electric Co., Ltd. has reinforced its factory automation monitoring and control systems. Particularly, the company has introduced a new addition to its existing MICREX-VieW FOCUS Series automation monitoring and control systems for plants.

Furthermore, the MICREX-VieW FOCUS Evolution has been made capable of flexible system construction to fit customer issues.

Background

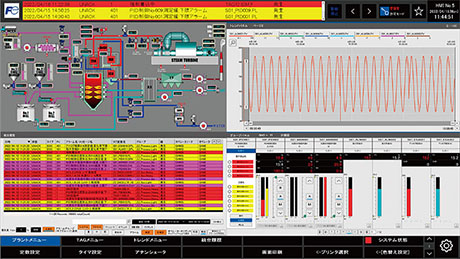

Industrial plants that produce electric or gas energy, iron and non-ferrous metals, and chemicals generally introduce monitoring and control systems. Primarily, the purpose is to achieve stable plant operation. Most importantly, those systems must allow equipment operators to flexibly modify specifications themselves in response to issues on the shop floor and changes in the real world.

Monitoring and control systems are products that monitor and control plant conditions using data. These data include equipment operation status and product processing and production information.

In 1994, Fuji Electric launched the MICREX-VieW FOCUS series of monitoring and control systems for small- and medium-sized industrial plants. The systems have been installed at many industrial plants mainly in Japan, including steel, chemical, cement, and waste incineration.

The newly launched MICREX-VieW FOCUS Evolution has achieved high reliability and allows flexible system construction without specialized knowledge. Moreover, it also adopts OPC UA, an international standard communication protocol, intended for global market.

Meanwhile, Fuji Electric will combine this control system with the drive and measurement equipment that industrial plants require. At the same time, propose solutions that meet customer needs including labor saving and remote monitoring.

The company will also strive to expand its overseas plant business, particularly in Southeast Asia and India.

Product Features

Enables easy, quick, and flexible system construction

Fuji Electric has wide-ranging operational expertise that it has acquired through the industrial plants business. In addition, the system incorporates this expertise as control programs, allowing flexible setting of combinations of control methods and devices required for a variety of processes and equipment for all kinds of plants by simple drag-and-drop screen operation.

Furthermore, the set combinations of control methods and devices can be stored in the system as application packages. Hence, shortening construction period because they can easily and quickly reflect in different processes and equipment either at the same site or in other sites.

Contributes to stable plant operation with a highly redundant system

Storing plant data in multiple operator machines allows immediate data restoration immediately in cases of failure. Thus, allowing continuous operation of plant equipment.

Uses proprietary database as a standard feature

Fuji Electric has developed a proprietary database included as a standard feature. For that reason, eliminating the need for new commercial database software (such as SQL Server*) and reducing installation costs.