ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

DNP’s New Line Boosts Capacity for Coating Devices

Dai Nippon Printing (DNP) has significantly increased the production capabilities of its Mihara facility in Hiroshima, Japan. Particularly, it will integrate additional wide-range coating devices.

The wide-range coating devices will be suitable for the manufacture of high function optical film with a maximum width of 2,500 mm. The device has been added at the Mihara plant in Hiroshima prefecture in response to the ongoing shift to large screen televisions.

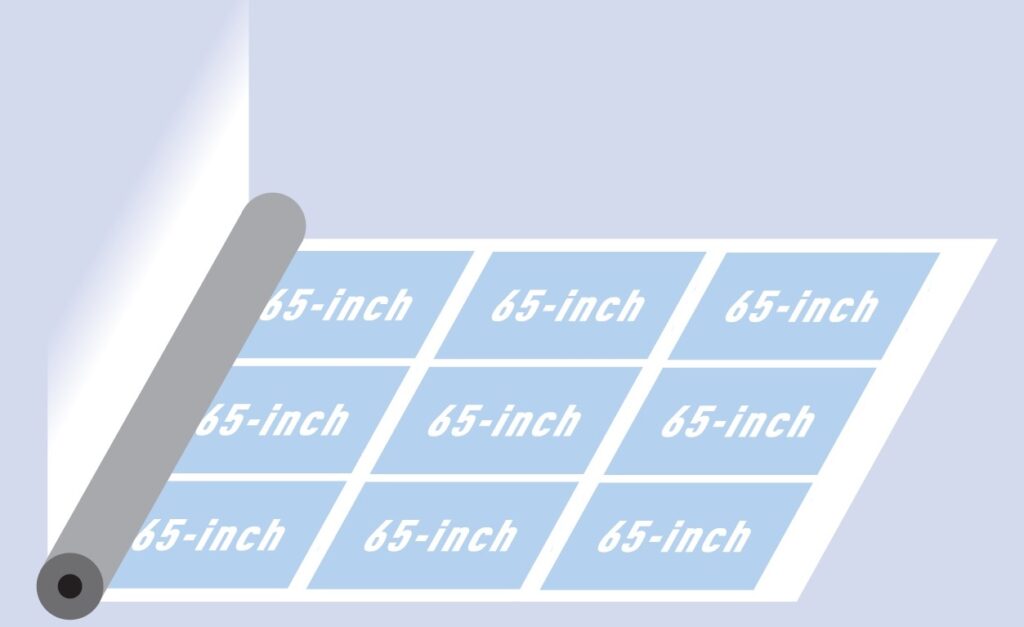

DNP has introduced a new coating device capable of accommodating a 2,500 mm width as a second manufacturing line. As a result, the production capacity, on an area basis, has increased by more than 15 percent. Hence, boosting the productivity of film for 65-inch large-screen TVs, with horizontal and vertical dimensions of 1436.4 mm x 809.0 mm. Due to this upfront investment, DNP is now able to rapidly respond to the growing demand for optical film for large displays, which will expand further.

Strengthens High Function Optical Film Manufacturing Line

In line with the shift to large screen televisions in recent years, DNP sees increased demand for the large scaling of various components for displays. These include panels, polarizing plates and film. According to the UK based market research company Omdia, the combined area of TVs and PC monitors will increase at a compound annual growth rate (CAGR) of 5 percent from 2022 to 2026, and 4 percent from 2022 to 2029.

In addition, as large 65-inch TVs become the mainstream, manufacturers of panels and polarizing plates in China are boosting production lines to stay abreast of such large-scaling. Furthermore, to also accommodate improvements in production efficiency. This had fed into a growing need for high function optical films for TVs that support 2,500 mm widths.

In response to these trends, in 2018 DNP led the world by introducing a coating device for 2,500 mm widths, which allowed for efficient extraction of film for 65-inch displays from produced optical film2 into the production of protective optical films for polarizing plates. Moreover, to further leverage this superiority, the company decided to add a new wide coating device at its Mihara plant.

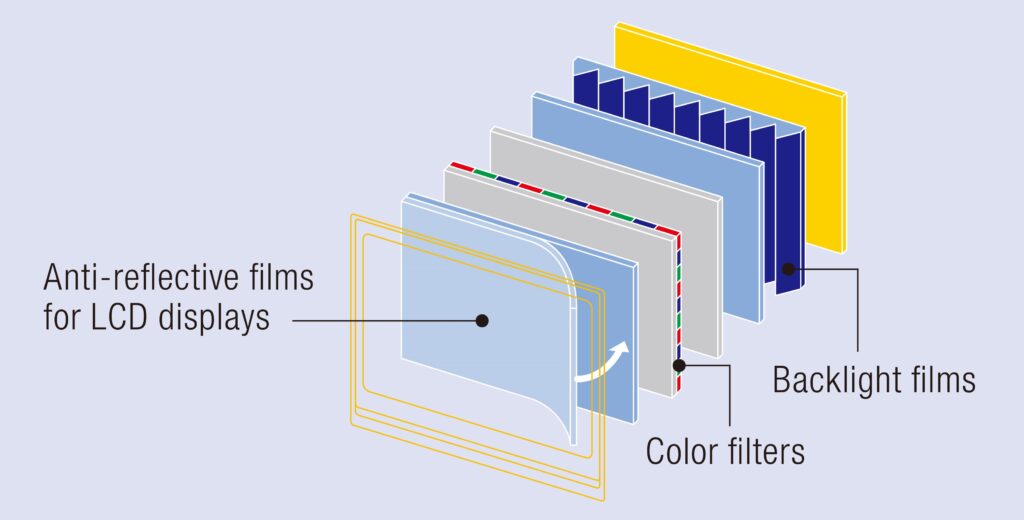

At the same time, the newly added wide-width coating equipment is designed to be able to coat two layers at the same time. As displays become more sophisticated and diversified in the future, multi-layered coatings will become necessary, and we will continue to meet the demand for Anti-glare-Low Reflection (AG-LR) film and Low Reflection (LR) film.

Efficient Production

The 2,500 mm width film produced on the new line makes it possible to efficiently manufacture high function optical film for 65-inch displays. Particularly, this size has seen tremendous demand globally.

The new line has been designed for the productivity of the multi-layer coating that is important in order for improving the anti-reflective function and performance of high function optical film. The additional coating equipment will reduce CO2 emissions by 30% annually compared to currently used devices. This is because of the new technology that reduces power consumption and via production process innovations.

DNP pegged the capital expenditure for the new line to be approximately ¥13.0 billion.