ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Resonac Automates Material Inspection Using Deep Learning

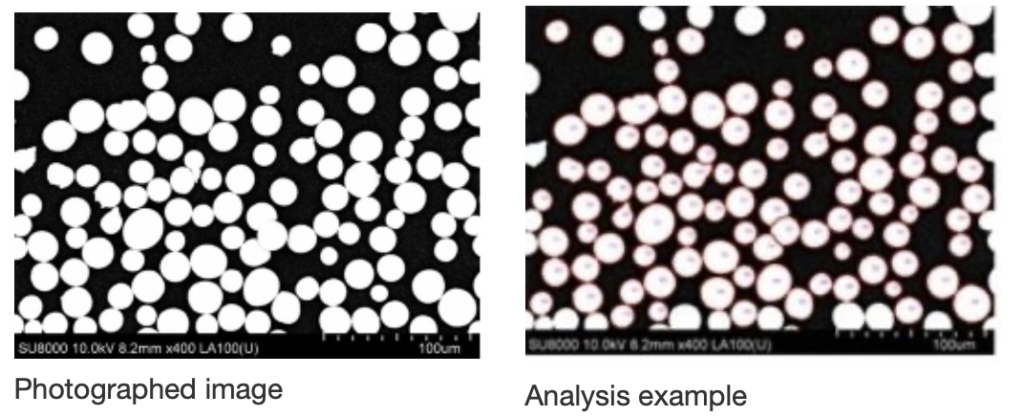

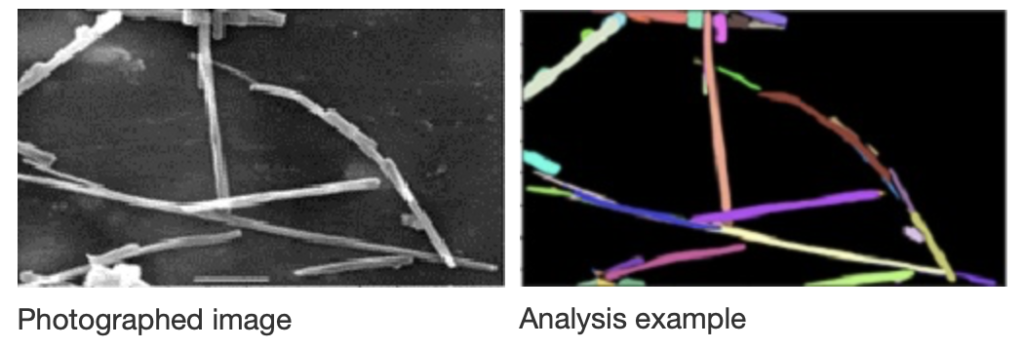

Resonac Corporation has succeeded in automating product development and inspection, and in significantly reducing the time required for inspection. The company utilized deep learning*1 and image analysis for material inspection to achieve these. Specifically, these technologies have been making remarkable progress in recent years. For example, the inspection time for solder particles used in anisotropic conductive film was reduced to 1/140th of the time it previously took. Meanwhile, the inspection time for graphite fiber used as a conductivity aid for cathodes and anodes of lithium-ion secondary batteries was reduced to 1/3rd of the conventional time.

Typically, the inspection processes for solder particles and graphite fibers consisted of visual inspections. However, the process involves some issues, like it was time-consuming and involved many processes Also, there were variations in the amount of time it took for different inspectors to perform the inspections. Meanwhile, automating the inspection processes using deep learning required having a vast number of images that would make up the basis for learning, engineers specializing in deep learning, and computers with powerful data processing capabilities.

The team at the Research Center for Computational Science and Informatics succeeded in automating material inspections. The team is dedicated to the development of the image analysis system. Specifically, it leveraged the capabilities of a team specialized in deep-learning-based image analysis and introduced unique technologies.

In the development process, the team introduced an advanced image processing technology that enables the system to learn and perform analysis using just a small number of images. Also, it narrowed down the deep learning areas for inspection, then, introduced a web application. Moreover, the team also communicated closely with those who would perform the work on the manufacturing floor. Then, it prepared high-quality images for deep learning. This enabled automated material inspection. Specifically, it simultaneously eliminated the variations in the amount of time it took for different inspectors to perform inspections.

To obtain highly accurate results, we developed a number of unique innovations. Among them include combining conventional image processing techniques with deep learning based on its operating principles and combining multiple deep learning models.

Going forward, the Research Center for Computational Science and Informatics plans to increase the number of engineers capable of performing image analysis by developing in-house expertise in image analysis. Also, it will develop intra-company web applications that utilize image analysis and large language models.

Development Process

This image-processing technology enables learning and analysis using just a small number of images.

While deep learning typically requires thousands of images as a basis for learning, we can now use deep learning with as little as a few dozen images. This is possible due to a technique that allows us to obtain multiple images from a single image*2. Subsequently, the learning is transferred to a model already learned from other data and tuned using the target data.

Narrowing down the deep learning areas to be used for inspections

Typically, training engineers specializing in deep learning takes time. Thus, the range of operations used in materials inspection is limited. We were able to train engineers quickly by focusing on technologies for analyzing three essential areas. These areas are calculation, measurement, and classification.

Web application deployment

We created a setup where deep learning calculations are performed on a high-performance server in the cloud. Then, we provided users with a web application connected to the cloud server through a network, thereby enabling users to conduct image analysis on a business-use mobile PC.

Also, we facilitated maintenance and management work on the part of software developers with the use of cloud.

References:

*1. Deep learning: A method used to teach artificial intelligence (AI) how to process information.

*2. Multiple images are obtained by making adjustments to a single image, such as left-right inversion, saturation, etc.