ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Mitsubishi Electric, Evercomm Partner on Decarbonization

Mitsubishi Electric Corp. and EVERCOMM SINGAPORE PTE. LTD. jointly announced that they have entered into a cooperative agreement to develop and market solutions that support carbon neutrality in the manufacturing sector. As part of the agreement, Mitsubishi Electric will take an equity stake in Evercomm to solidify the ties between the two companies.

In recent years, the global movement toward carbon neutrality as a measure against global warming has accelerated. Companies, particularly in the manufacturing sector, are facing increasing demands from stakeholders, such as governments, shareholders, business partners and consumers to implement measures to manage and reduce CO2 emissions. As a result, there is a growing demand from each company for solutions to manage and reduce CO2 emissions.

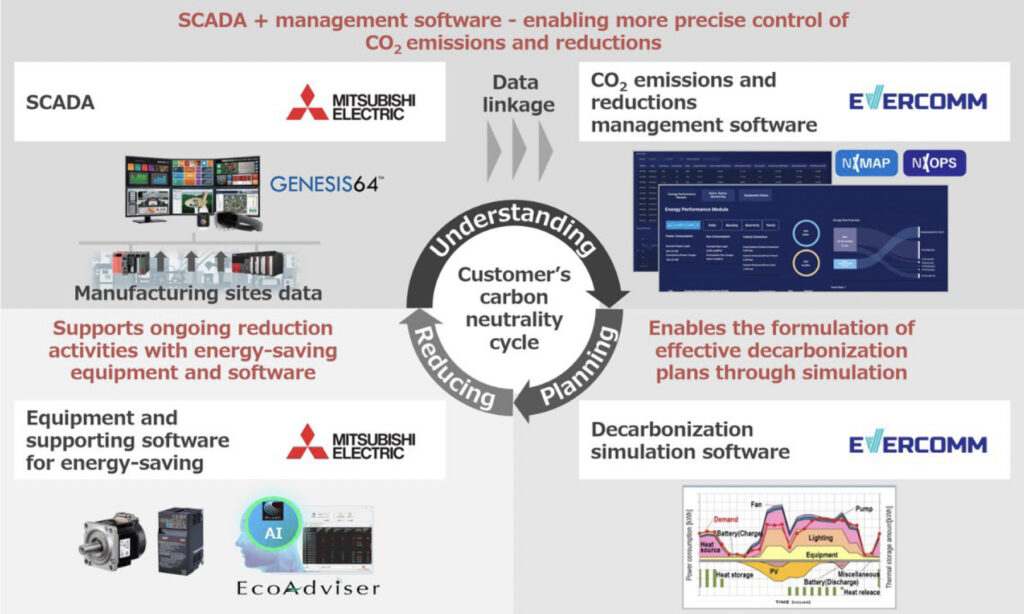

For its part, Mitsubishi Electric provides solutions that support digital transformation in manufacturing sites by software. One of them is supervisory control and data acquisition (SCADA1) software. Additionally, the company sells inverters, motors, and other energy-saving equipment that help to reduce CO2 emissions. It also markets analysis and diagnosis software that support energy-saving.

Meanwhile, Evercomm provides an ISO14064-12-based service for managing data on CO2 emissions at the corporate level. Specifically, it is a system that allows data verification by third-party certification organizations. Also, it offers ISO140673-based software allowing calculation and management of the carbon footprint of products (CFP4) at the individual product level. Moreover, the company also provides software, primarily in the ASEAN region, that facilitates the development of decarbonization plans. The software identifies specific potential emission-reduction measures and simulates their potential effects.

Through the collaboration, the two companies will contribute to the realization of carbon neutrality for their customers. Together, they will provide solutions that incorporate Evercomm’s software and Mitsubishi Electric’s products and software. Mitsubishi Electric’s SCADA using Evercomm’s management software will collect manufacturing site data of CO2 emissions and reductions. After consolidation, an environment that enables more precise control of measures designed to achieve carbon neutrality will be created. Furthermore, based on aggregated data, Evercomm will enhance decarbonization planning support by its decarbonization simulation software. Mitsubishi Electric will provide optimal energy-saving equipment and energy-saving support software that helps achieve CO2 reductions and support for ongoing CO2 reduction activities.

Chen Chiu-Hao, CEO of Evercomm said: “Embracing the sustainability urgency, we are eager to pioneer the frontier of sustainable development with environmentally conscious partners. Our alliance with Mitsubishi Electric serves as a catalyst for this mission, providing us with access to their expansive digital transformation capabilities. This partnership goes beyond the confines of mere technology – it embodies a collaborative endeavor to jointly equip our clients with the critical tools required to turn their sustainability ambitions into reality, guiding them step by step towards achieving carbon neutrality.”

Toshie Takeuchi, Group President of Mitsubishi Electric’s Factory Automation Systems Group, said, “Evercomm’s software is attractive because it manages CO2 emissions and the data required to manage CO2 emission reduction activities, and includes a mechanism for third-party certification of the data. This time, in collaboration with Evercomm, we will provide a one-stop solution that will enable companies to analyze the current state of their CO2 emissions and to develop decarbonization planning CO2 reduction initiatives, thereby contributing to the realization of carbon neutrality in the manufacturing sector.”

1. Software for data collection and supervised control in manufacturing utilized by factory automation equipment, such as programmable logic controller

2. Guidelines for reporting greenhouse gas emissions in an organization

3. Specifies requirements and guidelines for product carbon footprint calculation and communication

4. A system that converts the amount of greenhouse gases emitted throughout a product’s life cycle, from procurement of raw materials to disposal and recycling, into CO2, and displays it on products and services.