ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Automated Tools Boost Surface Mount Productivity

Although surface-mount assembly involves great precision and reliability, things can go wrong when operating continuously at high speed. Furthermore, in the event of errors and exceptions, the team in charge of production needs to restore full-speed operation as quickly as possible.

Line stoppage incurs costs for businesses that detract from profitability. These costs include not only the direct cost of lost production but also labor costs while the line is stopped, the cost of overtime and rush orders to catch up after the line is restored, and the cost of any rework or items scrapped due to the problem that caused the stoppage. There are costs associated with inventory waiting and the disruption to the normal flow of operations can cause inefficiencies. Moreover, there can be impact on customer commitments that can result in financial penalties.

On the other hand, it can be important to stop the line, when there is a problem, to prevent production of defective units. The operator or production supervisor needs to know as quickly as possible of any error. Line stoppages are undesirable and manufacturers need to ensure this happens as infrequently as possible. Moreover, this ensures best productivity and minimize unwanted costs. When stopping cannot be avoided, production needs to be restored as quickly as possible.

Tools for Troubleshooting

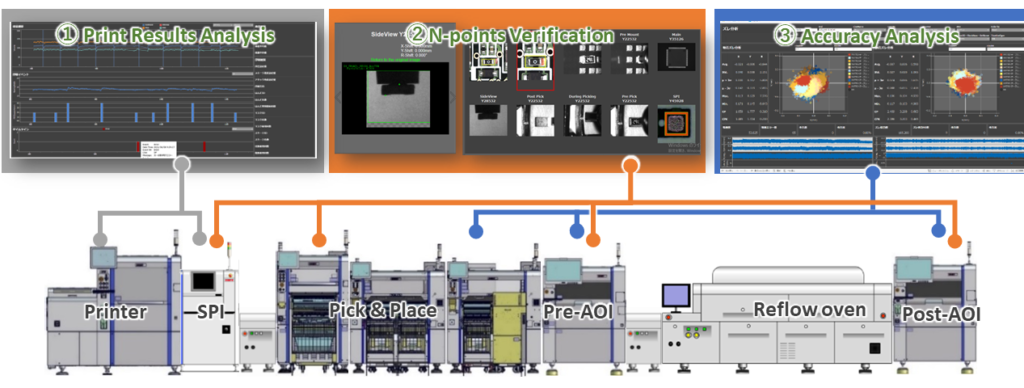

Presently, assembly equipment has sensors to detect issues such as blocked nozzles or pickup misalignment. Furthermore, automatic inspection can be performed at multiple points in the line, including after screen printing, component placement, and reflow, using the results to assist in troubleshooting in real-time.

Manufacturers rely on software tools to help manage production equipment, detect any exceptions and defects, and provide information to production supervisors. These include dashboard applications that provide an instant appraisal of equipment and production status. There are also value-added tools such as Yamaha’s QA Options and the closely related Mobile Judgement app. Mobile Judgement can send details of any detected defects, including inspection images, directly to the supervisor’s smartphone. Hence, helping assess the severity of the problem. Based on personal judgement, the supervisor can instruct the line to stop immediately if necessary, until the issue can be solved.

The Human-Machine Interface

These types of applications represent the place where machines and humans interact to solve problems. Particularly, those that inevitably arise during the normal course of a shift. The team in charge must apply their skills to deliver the required quantity of each batch and ensure that production runs to schedule.

This approach can be dependent on the quality of the tools provided to visualize the data captured from the various locations throughout the line. Identifying the causes of faults and applying a fix, quickly, also depends on the skills and knowledge of the supervisor staff members present in the factory. If the company’s top supervisor is not on duty for any reason– they are working another shift, on vacation, perhaps on sick leave – productivity could be impaired.

The latest advancements in data science can help to eliminate dependence on individual judgement. Particularly, by automatically identifying the causes of any defects or other production problems. Guiding operators directly to these causes permit more consistent production performance. For example, the latest Yamaha YSUP Analytics Dashboard contains advanced tools that use statistical techniques to identify causes of detected defects. It also recommends suitable corrective actions. Moreover, the analytics tools work in addition to graphical tools that help visualize the performance of equipment (figure 1).

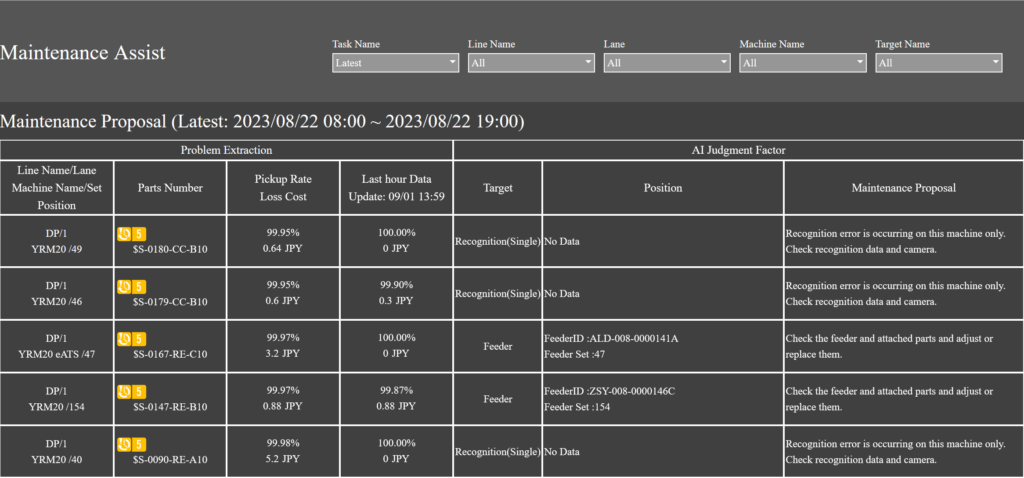

The new YSUP Analytics Dashboard presents information in an easy-to-read format that can be interpreted at a glance. Ultimately, this enables every working shift to deliver consistently high production throughput and end-of-line yield and drastically reduces stoppage time.

Based on a relational database with built-in querying capabilities that analyze data in situ, the software identifies probable causes of recorded exceptions. The automatic analysis capabilities of the new dashboard application enable any authorized user to extract the information they need. Thus, enabling them to analyze errors, and view corrective actions at any time.

The tools available include automatic pickup error analysis, which uses analytical methods. This includes flow judgement, error-code diagnostics, health-check data diagnostics, and image-recognition diagnostics. The user can view the time and circumstances of any pickup errors, see the exact location, and view corrective actions (figure 2).

Moreover, Yamaha has verified the accuracy of automatic pickup error analysis using this tool in experiments performed with a lead customer, a major automotive tier-1 manufacturer. There are also built-in capabilities that assist root-cause detection. These include management of automatic judgement results and countermeasure content tracing.

The power of the underlying platform provides scope to add further analytics tools, such as placement analysis and print analysis. Moreover, the platform is open to leveraging artificial intelligence (AI) in future distributions. This will provide additional analytics capabilities and further accelerate problem-solving directly on production lines.

Conclusion

Automation has enabled electronic manufacturers to remove human limitations from many activities on production lines. However, intervention has remained necessary where judgment must be applied and assistance is necessary. This handles exceptional circumstances and restore correct operation.

Finally, the latest data-driven dashboard tools provide extra assistance to identify and fix the causes of errors. They help overcome the limitations of operators’ knowledge and shorten the time to restore operation. Thus, ultimately enabling further improvement of productivity.