ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yamaha Offers Unique Solutions to Faber Electronics

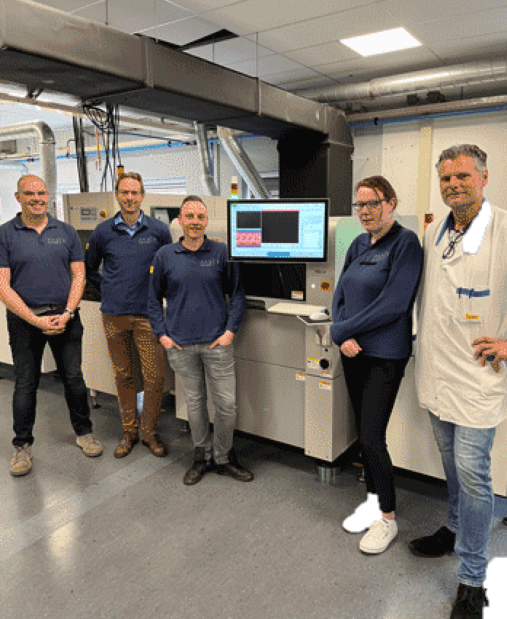

Yamaha Motor Europe SMT Section is supplying high-speed equipment for two surface-mount lines at of Dutch firm Faber Electronics. Particularly, Yamaha Motor Europe will build high-tech products including IoT equipment, automotive electronics, medical devices, and industrial controls.

Recently, Netherlands-based Faber Electronics has installed a Yamaha YCP10 screen printer. At the same time, it also installed two YSM20R high-speed mounters and a YSi-V AOI system for end-of-line visual inspection.

Strengthens Quality Assurance

Tijmen Augustijn, Operations Director at Faber Electronics, said, “Our customers serve markets that expect extremely high product reliability, so faultless assembly at high speed is a pre-requisite.”

“On the other hand, we pride ourselves on our flexibility to adapt quickly whenever their requirements change. We expect our technology partners and suppliers to help us meet those demands. With that in mind, we decided to extend our connection with Yamaha by investing in new equipment from the 1 STOP SMART SOLUTION,” Augustijn added.

The drive for reliability leads Faber Electronics’ engineering teams to place a high value on design for manufacture (DfM) and design for test (DfT). Typically, in-circuit testing complements 100 percent of boards produced or a high proportion, depending on individual customers’ requirements. The YSi-V AOI system in each assembly line helps strengthen quality assurance and maximize productivity by quickly identifying any boards that have visible defects.

Daisuke Yoshihara, General Sales Manager for Yamaha adds, “Faber Electronics now has two full SMT lines perfectly conceived to fulfil their customers’ demands. Delivering a clear competitive edge and a future-proof return on their investment.”

Advanced Features, Ease of Use

The YSi-V’s multi-angle and multi-wavelength lighting helps the system spot defects that are difficult to see in ordinary light and can prevent shadows from obscuring inspection areas. In addition, laser height measurement can detect coplanarity issues that may indicate damage to component pins or a soldering defect. Hence, the system is an ideal companion to the compact YCP10 printer, which has advanced features and can handle large board sizes. Furthermore, another is the high-efficiency YSM20R mounter with up to 95,000 cph placement capability.

Marc Valk, Quality Assurance Engineer at Faber Electronics, commented, “Our customers trust us always to respond quickly to their needs. The advanced features and ease of use we enjoy with our Yamaha surface-mount lines help us maintain that reputation. We can handle anything from last-minute design modifications to frequent product changeovers quickly and efficiently.”

Meanwhile, Theo Loohuis Service Manager of Europe-SMT, Yamaha’s distributor for Benelux, the combination of YCP10 printer, YSM20R mounters, and YSi-V AOI in each line provides advanced capabilities that will meet Faber Electronics’ requirements far into the future. “Each line can print, place and inspect, at high speed, parts ranging from the smallest SMD chips to large ICs like FPGAs and tall components like capacitors and connectors. We listened to their team to understand their requirements and their vision for the future. We then worked with Yamaha to propose the best package to meet their needs. Each line ensures high production quality with the flexibility to meet diverse and fast-changing customer demands.”