ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Why Omron's New SECS/GEM Solutions Benefit IC Makers?

As a trusted partner in automation solutions for the semiconductor industry, Omron is committed to providing highly innovative technologies that also meet SECS/GEM requirements. Let’s take a look at the purpose behind SECS/GEM and the ways in which these solutions will benefit semiconductor manufacturers.

What is the purpose of SECS/GEM?

SECS/GEM describes how semiconductor manufacturing equipment is supposed to communicate with the manufacturing execution system, or MES for short. Within the standard, the MES is often referred to as the “host.” SECS defines the contents of messages, while the General Equipment Model (E30) or GEM is a higher-layer protocol that defines the messages themselves.

The GEM standard is limited to defining the behavior of the semiconductor equipment as viewed through a communications link. The SEMI E5 (SECS-II) standard provides the definition of messages and related data items exchanged between the host and equipment. The GEM standard defines which SECS-II messages should be used, in what situations, and what the resulting activity should be.

The SECS/GEM standard describes two-way communications through a network or serial cable connection that is independent of any operating system or programming language. Typically, the host side of a connection will be executing on a computer system provided by the factory, while the equipment side runs on a controller provided by the OEM.

By defining messages, state machines, and scenarios, SECS/GEM allows factory software to control and monitor manufacturing equipment. It facilitates true interoperability and can be applied to virtually any manufacturing equipment in any industry.

What is driving the adoption of SECS/GEM within the industry?

Demand for SECS/GEM-compliant solutions is driven by semiconductor production, consumer interest in electronic products, and corporate spending on information technology. This area of manufacturing involves some of the most challenging and complicated production systems, and these involve significant capital investment and advanced technologies.

Automation and integration are the keys to success in modern semiconductor manufacturing. Moreover, process automation is critical for ensuring the quality and throughput of process sequences and corresponding parameter settings, as well as integrating all fabrication activities to provide the requisite efficiency, reliability, and availability.

Many companies are under pressure to innovate without capital expenditure in a tight currency market, so a top driver for SECS/GEM solutions includes companies looking to retrofit equipment and improve quality.

Common applications in front-end manufacturing include:

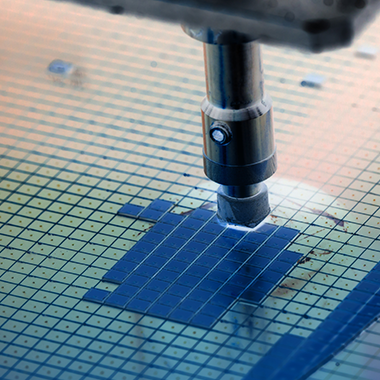

- Wafer Inspection

- Wafer Processing

- Wafer Transportation

Common applications in back-end processes include:

- Wafer Testing

- Wafer Packaging

- Wafer Transportation

What Omron offers

Omron’s NJ Machine Automation Controller with SECS/GEM functionality provides direct communication to the Host PC in a single platform controller, complete with embedded EtherCAT for real time I/O, motion, vision, and safety. Furthermore, the NJ501-1340 supports the V640 RFID system used for tracking FOUPs (wafer carriers).

The following products are available for use with the NJ SECS/GEM:

- NJ SECS/GEM CPU Unit NJ501-1340 which complies with E37-0303, E37.1-0702, E5-0707, and E30-0307

- NJ Series Power Supply which complies with F47

- Ethernet Cable

- Sysmac Studio Standard Edition SYSMAC-SE201D

- Sysmac Studio License SYSMAC-SE2☐☐L

- SECS/GEM Configurator License WS02-GCTL1

Note:

The contents of this article has been lifted from the website of Omron Automation.