ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NSK Develops New Ball Screws for Injection Molding

NSK has developed HTF-SRM Ball Screws, a high-speed, heat-resistant version of its high-load drive ball screws. Particularly, this has been ideal for high-cycle, thin-wall molding in electric injection molding machines.

NSK will begin accepting orders of this product in April 2024, with a global rollout to follow. Most importantly, the company aims to achieve annual sales of 500 million yen by fiscal 2026 for this product.

Background

In recent years, demand for plastic products has been on the rise due to an increasing world population and increasing living standards in emerging economies. At the same time, as part of the SDGs and carbon-neutral initiatives, there is a growing demand for more environmentally friendly products.

For that reason, electric injection molding machines used to manufacture plastic products require high-cycle performance to improve productivity and increasing demand. Moreover, with the ability to mold thin-wall plastic parts to reduce plastic material consumption and environmental burden.

Against this background, there is demand for high-load drive ball screws for electric injection molding machines. Particularly, to enable higher cycle speeds and thin-wall molding. High-cycle means faster operating speeds that require countermeasures to deal with the accompanying additional heat generation.

Features

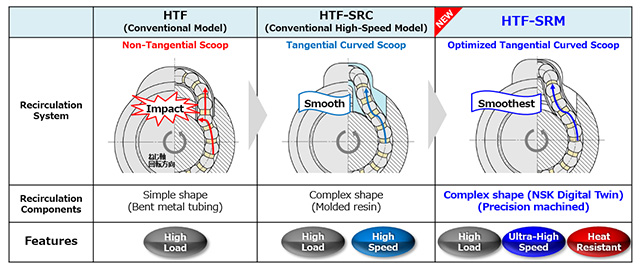

The newly developed Smooth Return Metal (SRM) coupling recirculation system and heat-resistant components achieve the industry’s highest level of operating speed. At the same time, it also possesses high heat resistance as well. The permissible d-n value1 is 200,000, a 40% improvement over NSK’s conventional high-speed HTF-SRC ball screws. The maximum operating temperature is 90°C and the momentary maximum temperature is 100°C, both of which are 20°C higher than NSK’s conventional products.

The external dimensions of the screw and nut are the same as those of the HTF-SRC model. Thus, eliminating the need for design changes when upgrading.

Technology

1. Newly Developed SRM Recirculation System

One of the technical challenges associated with higher speeds is the higher impact force of ball recirculation. Hence, resulting in damage to the recirculation parts and ball screw shaft. The company has completely overcome this issue by applying NSK Digital Twin technology to optimize the recirculation path.

2. Steel Recirculation Components

The SRM Recirculation System is a complex steel shape manufactured with precision machining technology. The result is smooth ball recirculation and improved heat resistance. Thus, breaking through the limits of conventional resin (plastic) materials to achieve higher speed and higher heat resistance than ever before.

3. Heat-Resistant Materials

Heat-resistant materials are used for the seals and resin components, and the design has been further improved to enhance heat resistance.