ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Emerson's New Ultrasonic Welders Offer Novel Welds

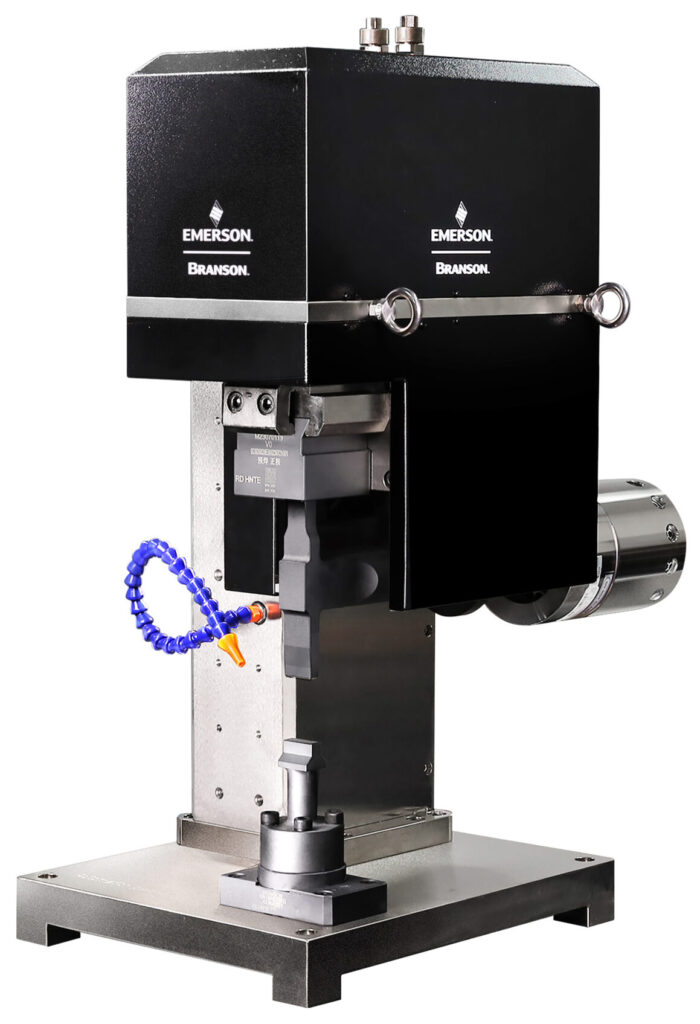

Emerson has launched the Branson™ Series GMX-Micro, a line of high-precision ultrasonic metal welders. Particularly, they feature a new computerized operating system, multiple power levels and configurations, advanced controls, and improved connectivity.

Thus, the new welders can meet changing material and production requirements for electric vehicle batteries, battery chargers, conductors, and electronics applications, with faster cycle times that can increase productivity and reduce costs.

Redesigned and upgraded from the existing Branson GMX-20MA and GMX-20DP welders, the GMX-Micro series is available in two power levels. Namely, the one with 4,000 watts of welding power, the GMX-Micro, and the more powerful 5,500-watt GMX-Micro, which is available with either a standard metal welding stack or a direct press weld stack. The direct press stack can exert higher downforce with greater stability. Thus, making it possible to complete complex, many-layered battery film welds or large-conductor welds with greater stability and consistency.

“Emerson has engineered the new Branson GMX-Micro series welders to help electric vehicle, battery, and charging system manufacturers increase the output and quality,” said Alex Yeung, global business development manager, metal welding, Emerson. Thus, Yeung said, they reliably bond the larger conductors now required for rapid charging at higher voltages.

Innovative Functions, Features

The GMX-Micro welders feature all-new power supplies and controls, including an upgraded pneumatic actuation system that resets more quickly. That is, within 100 milliseconds of weld completion. Thus, enabling faster weld cycles and greater production rates. Weld stacks come in rigid polar mounts, while actuators feature dual linear bearings. On the other hand, the integral height calibration and a linear encoder with 5-micron resolution eliminates the need for external measurement devices.

These features, together with a nodal support design that precisely balances the GMX-Micro weld stack and horn with the anvil during welding. Thus, ensuring effective ultrasonic energy transfer and repeatable, high-precision bonding.

Users of the all-new GMX-Micro power supplies (5,500 or 4,000 watt) manage welder functions through a standard 7-inch LCD touchscreen. On the other hand, with optional extended display, that can develop, store or retrieve weld recipes quickly. The display also graphs critical weld parameters — power, height or frequency — in real time. Moreover, the new power supplies also provide extensive weld-quality data capture and storage, and multilingual operation.

The new GMX-Micro series comes on a compact, modular chassis, with two styles based on the choice of normal or direct-press actuator. The series comes with a design that simplify configuration, automation, and mounting of single- or multi-welder systems. Both chassis offer expanded working space below the actuator. Hence, allowing easier insertion and removal of larger parts.