ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yamaha Unveils Latest Upgrades in 3D AOI Systems

Yamaha Motor Co. Ltd. has revealed performance-boosting upgrades for the YRi-V 3D AOI system. Particularly, these upgrades include faster board handling, multi-component alignment checking, and enhanced LED coplanarity measurement.

The new stopper-less transfer system brakes and stabilizes each board electronically after entering the machine. Thus, cutting the time to position the assembly ready for inspection. The cumulative time saving accelerates the completion of every batch and significantly increases overall productivity.

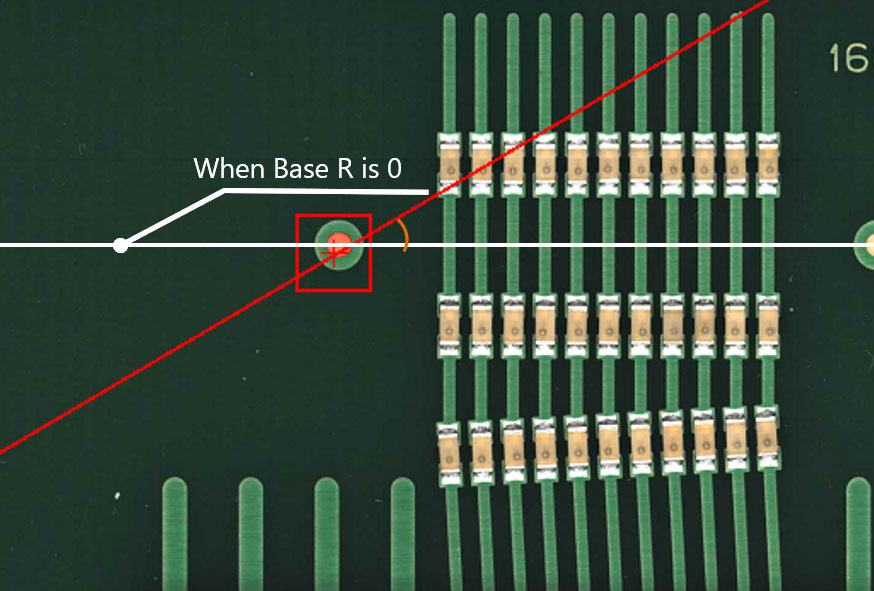

Moreover, the new multi-component alignment check simplifies programming the YRi-V to measure the distances between arrayed parts. Specifically, LED emitters in automotive or general lighting. When building automotive headlamps, users can leverage the captured AOI data to individually optimize the placement of beam-focusing lenses for maximum lighting performance. The alignment check can verify the spacings between many other types of components, such as Hall sensors for precision motion control.

Suits Various Manufacturing Demands

The upgraded height measurement system, using a blue laser, ensures accurate and repeatable height assessment for components. Particularly, those that are difficult to capture with standard equipment, such as transparent LED packages. Now offering superior capabilities, the YRi-V helps lighting manufacturers ensure greater product reliability with superior optical performance and visual appearance.

In addition, the YRi-V can be now equipped with a 25-megapixel top-camera system, which significantly expands the inspection area that can be imaged at one time.

“Our latest upgrades further extend the YRi-V’s ability to maximize quality assurance, addressing cutting-edge automotive, industrial, and consumer applications,” said Daisuke Yoshihara, General Sales Manager.

Furthermore, Yoshihara said their customers benefit from ongoing enhancements to the YRi-V systems. Specifically, as new features available enabled by advancements such as new machine-vision technologies, motion control, and AI.

Reliable Features, Functions

Yamaha’s YRi-V 3D AOI system features a high-rigidity frame, shared with the advanced YRM high-speed mounters. These serve as the foundation for super-sharp image capture operating at the maximum line rate.

With multiple camera-resolution options, an 8-direction 3D projector, and a state-of-the-art image-processing engine, the system achieves extremely high throughput. Also, it detects elusive defects such as chips and cracks in wafer-level packages. Offline editing tools and AI-assisted auto library matching accelerate inspection program generation to help minimize new-product introduction time.

There are also tools to facilitate data creation, conversion, and tuning. When operating, M2M communication with other equipment in the line instantaneously shares defect information to aid analysis and troubleshooting.

As a part of the 1 STOP SMART SOLUTION concept, the YRi-V connects with Yamaha’s full lineup of SMT equipment. This includes solder paste printing and inspection, high-speed component mounting, and smart factory software to ensure a high level of integration and coordination. Finally, the latest stopperless transfer, alignment checking, and advanced laser height checking features are available now with all new machines.