ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yamaha Motor Adds New High-End 3D AOI System

Yamaha Motor Co., Ltd. announced the addition of a new high-end specification YRi-V TypeHS to the YRi-V 3D hybrid automated optical inspection (AOI) system. Accordingly, achieving both high speed and high precision in operation suits electronic component mounting factories.

Moreover, the company said the new addition to the portfolio will be available effective March 1.

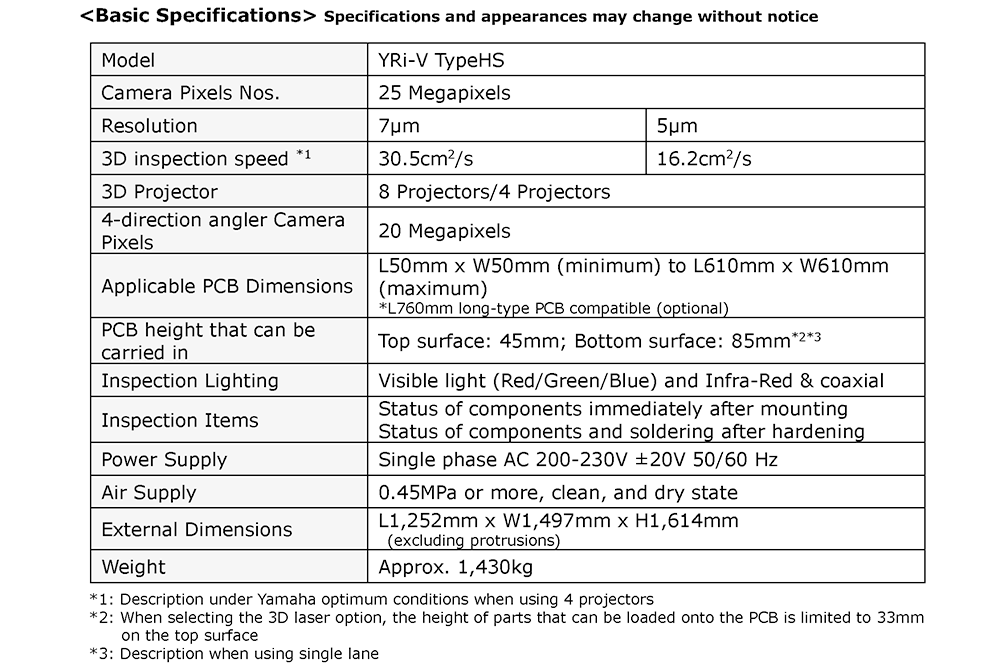

YRi-V TypeHS has significantly improved image processing capability by adopting a high-resolution 25-megapixel camera. Particularly, this is more than twice that of previous models. In addition, the new line also comes with the latest high-performance CPU and GPU applications. As a result, high-definition inspection with resolutions of 7μm and 5μm is approximately 1.6 times faster than previous models. Thus, making the new model one of the fastest in the industry.

Meanwhile, aside from the conventional high-precision 8-direction 3D projector, a high-performance 3D line laser has been newly installed. Hence, by combining this with 3D projector images using the phase shift method, it can reproduce more accurate shapes of specular and transparent components. Thus, further improving inspection capabilities.

This provides greater accuracy in detection capability for 0201 (0.25mm x 0.125mm) sized ultra-small chips and specular-glossy components. At the same time, further contributing to improved quality in module and device PCB production.

YRi-V TypeHS will be on show at the 38th INTERNEPCON JAPAN, Asia’s largest electronics manufacturing and packaging exhibition. The annual event will take place from January 24th to Friday, January 26th at Tokyo Big Sight in Tokyo, Japan.

Market Background and Product Outline

The reliability shown with SMT processes directly affects the market value of the products. The SMT field in recent years has seen the shift toward smaller sizes, higher densities, greater functionality, and more diversifications accelerate rapidly, and faster yet more precise inspection across all items via AOI will be even more sought after.

Recently, the use of thin and extremely small WLCSPs and FOWLPs,*¹ which have specular gloss on the package surface, has risen significantly. Thus, in addition to specular components that are difficult to inspect, the need for compatibility to mount ultra-small chips at narrow pitch is dramatically increasing.

In response to these market changes and demands, with the YRi-V being developed and released in July 2021, Yamaha Motor has produced an AOI system that is extremely fast and highly accurate, achieving accurate detection even for 0201-sized ultra-small chips and specular glossy components.

Moreover, the new YRi-V TypeHS high-end specification machine for the YRi-V further refined its traditional features. This includes achieving inspection speed and specular component inspection abilities.

With Yamaha Motor’s unique concept of a 1 STOP SMART SOLUTION, the Company is the industry’s leading manufacturer of a full lineup of mounting equipment. Particularly, surface mounting machines, SMD storage, solder paste printers, glue dispensers, and inspection system.

By leveraging this strength, the Company is promoting the Intelligent Factory, a smart system that comprehensively improves the efficiency of the mounting process. Specifically, through smooth and advanced inter-equipment coordination without black boxes in equipment within the mounting line.