ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Connector Firms Ramp up New Plant Construction

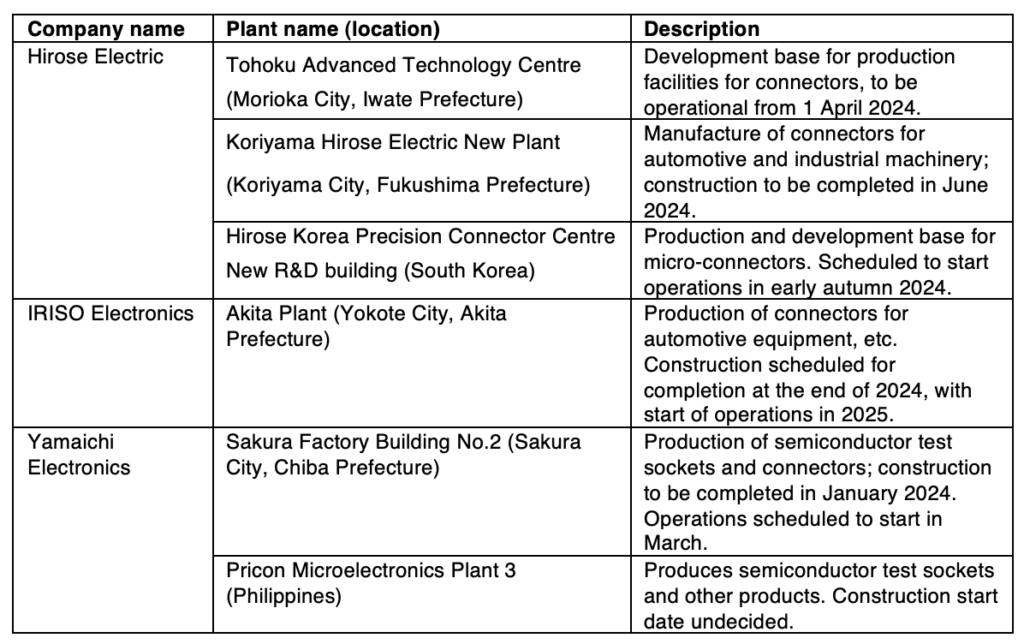

This year, connector manufacturers will continue to build new plants and expand existing plants both in Japan and abroad. Despite the gradual slowdown in connectors recently, companies will invest actively in anticipation of increasing global demand. Moreover, they plan to strengthen their manufacturing capabilities and promote business continuity planning (BCP). Specifically, major Japanese connector manufacturers are building domestic plants.

Global demand for connectors increased strongly from 2021 to autumn 2022, but demand slowed down after the end of 2022. In 2023, demand fell further due to sluggish demand for consumer and industrial equipment, the stagnant Chinese economy and prolonged customer inventory adjustments. According to the Japan Electronics and Information Technology Industries Association (JEITA), global shipments of connectors fell 12% year-on-year to 454 billion yen from April to Dec. 2023.

Nevertheless, medium- to long-term global demand for connectors is expected to continue to grow. Factors, such as computerization and electrification of automobiles, increasing functionality of 5G smartphones, growing smart factory-related demand, and increasing demand for artificial intelligence (AI) servers positively affect this trend.

Mainly, Japanese connector companies will continue to invest aggressively from 2024 to 2025 to build new plants, expand existing plants, and open new R&D centers. Further, they will strengthen their manufacturing capabilities by promoting more advanced production technologies and converting factories into smart factories and increasing production capacity in preparation for future demand growth.

HIROSE Electric: Development Base for Production Equipment

HIROSE Electric Co., Ltd. aims to strengthen its medium-term supply and manufacturing capabilities by reinforcing its production facilities.

Specifically, HIROSE started operations at its new development base for production equipment – the Tohoku Advanced Technology Center in Iwate Prefecture on 1 March. In June, a new plant of its subsidiary Koriyama HIROSE Electric Co., Ltd. in Fukushima Prefecture is scheduled for completion. The new Koriyama plant has a total floor area approximately 2.7 times that of the current Koriyama plant. It will be developed as an advanced manufacturing plant, focusing on in-vehicle and industrial machinery.

Additionally, HIROSE has added an R&D building to HIROSE Korea Co., Ltd. to strengthen the production and development of micro-connectors outside Japan. The new plant will start operations this autumn, with capacity set to increase 1.3 times than the present level.

IRISO Electronics: New Akita Plant

IRISO Electronics Co., Ltd. will build a new domestic plant in Akita Prefecture with construction to start in FY2023. It is set for completion at the end of 2024 and starts operations in 2025. This will be the company’s domestic production base following the Ibaraki Plant in Ibaraki Prefecture. The construction of the Akita plant is in anticipation of increased demand, mainly for in-vehicle equipment for xEVs, and of lower distribution costs and production efficiency through BCP and market-in by means of a multi-production system. The plant will have a site area of 58,000sqm and a total floor area of 22,000sqm.

In addition, a new plant for moulds started operation in Hanamaki, Iwate Prefecture in Oct. 2023. The plant processes and assembles moulding dies. Also, it carries out some die design.

Yamaichi Electronics: New Building at Sakura Plant

Yamaichi Electronics Co., Ltd. completed construction of a new building, the Sakura Factory Building No 2, at the Sakura Factory (Chiba Prefecture) site at the end of January. Specifically, the new plant aims to strengthen the production system for semiconductor test sockets and connectors. It began operations in March. The new building has a press area on the first floor and a plating area on the second floor. Its layout enables efficient production from material delivery through to pressing, cleaning, heat treatment, plating, and packaging.

Overseas, the company also resolved to acquire land for the construction of a new production plant in the Philippines to increase the production capacity of semiconductor test sockets. The area acquired is 33,696sq.m. The land is for the construction of a new production plant (Plant 3) for Philippine subsidiary Pricon Microelectronics, Inc. The company has yet to decide on the start of construction of the new plant.

HARTING Technology: New Vietnam Plant

Among overseas manufacturers, German connector manufacturer HARTING Technology established a new plant for connector production in Hai Duong Province, Vietnam in Nov. 2023. HARTING aims to minimize delivery routes and significantly reduce CO₂ emissions by producing directly in the vicinity of customers in the ASEAN region.

(from January 2024 onwards)

This is an English translation of a Japanese article originally published in Dempa Shimbun Daily.

-04 April 2024-