ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Japanese FA Companies Pitch High-end Mounters in China

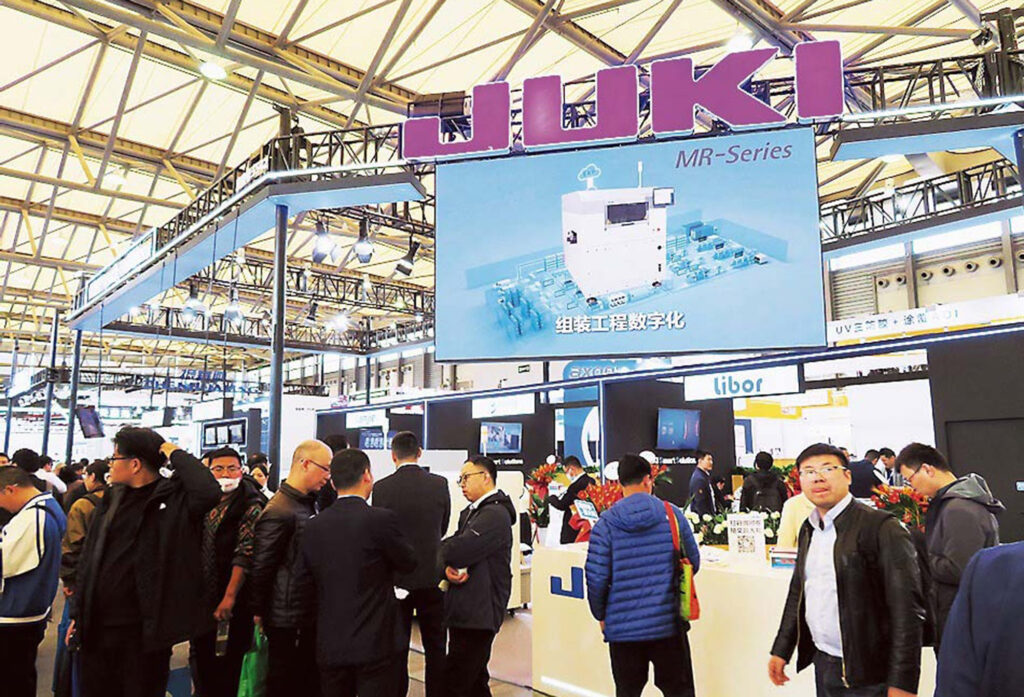

productronica China 2024, a three-day exhibition specializing in electronics manufacturing, industrial equipment and automation equipment, was held in Shanghai, China, from March 20 to 22. It attracted 60,657 visitors over three days. SMT-related equipment, including mounting machines, has begun to show signs of demand recovery in some industries since the end of last year, and capital investment is gaining momentum. The following is an introduction to the market initiatives in China of FUJI Corporation and JUKI Corporation.

FUJI Touts NXTR’s High-Speed, High-Precision Appeal

FUJI strengthens its proposal activities in the Chinese market, where smart factory and automation needs are increasing. At productronica China, FUJI showcased its next-generation mounting machine, NXTR, highlighting its high-speed, high-precision mounting technology.

The company displayed two types of NXTR: the A model and the conventional S model. Specifically, the A model featured a smart loader that automatically carries out set-up changes and material supply work. The top-level mounting speed and flexibility of the NXTR, which can configure the optimum line according to production, are highly appreciated in China.

In China, manufacturers are now adjusting smartphone inventories. Also, orders from EMS and Chinese smartphone manufacturers began to move at the end of last year. Sei Mori, General Manager of FUJI Machine China Co., Ltd., a local subsidiary in China, said “Compared to FY2023, the number of inquiries is increasing. We have finally hit the bottom and are beginning to see positive signs.”

While JUKI did not exhibit the AIMEXR at productronica China, it is doing well in this market. AIMEXR shows its strength in flexible production and is in high demand for servers, base stations, and battery-related applications.

Mori, said, “In the Chinese market, we aim to win orders with both the NXTR and AIMEXR. In China, where the need for automation is high, we can offer a wide range of our solutions”.

FUJI has a factory in Kunshan, China, where it produces printing machines. Currently, FUJI is looking at providing solutions to automate the changing of paper and solder cups.

JUKI Debuts the LX-8 to Meet Automation

Moreover, JUKI focuses on proposing various products aiming to increase its share of the Chinese market. At this year’s productronica China, the new LX-8 high-speed mounter made its debut in China. Also, the multitask platform JM-100 will be proposed for the smart energy sector, where demand is growing. This aims to increase its presence in the Chinese market.

Mainly, the LX-8 is a high-end model with high speed and high area productivity. It has 160 feeder slots and significantly reduces set-up time. The Takumi head, which can handle extremely small to large parts, reduces set-up changes, and achieves the highest throughput. In the future, the company plans to introduce a rotary head with enhanced high-speed performance, leading to further improvements in production efficiency.

Toshikazu Kirihara, General Manager of the Chinese subsidiary JUKI (China) Co., Ltd., says, “Customers have responded well to LX-8, which is being unveiled for the first time. Specifically, LX-8 is ideal for the high-mix, low-volume production that is common in China, and JUKI will propose it to the EMS market. Also, LX-8 enables small and medium-sized enterprises to build an optimized production line by changing heads, making it possible to save on investments.”

On the other hand, JM-100 is a versatile machine that supports high-speed insertion. Demand in the smart energy sector, such as photovoltaic power generation systems and household accumulators, is growing in China, and JM-100 attracted a lot of attention at productronica China.

Kirihara, said, “The smart energy sector is performing well, but a full-fledged recovery in demand is still some way off. Demand for automation is steadily beginning to emerge, and JUKI will offer the best solutions. We will enhance our technological capabilities so that customers will say ‘Leave automation to JUKI’.”

This is an English translation of a Japanese article originally published in Dempa Shimbun Daily.

-05 April 2024-