ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Japan's Electronics Traders Expand in SE Asia

Japanese electronics trading companies are getting back on their feet as the manufacturing industry gradually recovers from the COVID-19 pandemic. They have been stepping up their business in Southeast Asia by enhancing marketing systems.

Ryoden: Keeps Sales Expectation

Ryoden Corporation has three local subsidiaries in Southeast Asia. Ryosho Techno Singapore Pte., Ltd. handles semiconductors and devices. Ryosho (Thailand) Co., Ltd. mainly handles factory automation (FA) equipment, cold heat systems, semiconductors and devices. Ryosho Vietnam Co., Ltd., handles home elevators.

Ryosho Techno Singapore actively participates in the supply chain for semiconductors and electronic devices. It primarily targets Japanese customers with business in the Southeast Asian region.

Just like other countries Singapore implemented lockdowns as it dealt with unpredictable case of COVID-19 infections. Today, it aggressively implements vaccinations and pursues policies post COVID-19.

Tsuji Masato, Managing Director of Ryosho Techno Singapore, says, “We have customers for semiconductors mainly in Malaysia and Indonesia. They range from automotive electronics, home electric appliances to industrial equipment manufacturers. Although some customers have halted production amid COVID-19 in addition to semiconductor shortage, I expect that sales in FY2021 will advance as planned.”

Kanaden: Promotes High-Value Added Solution

In Southeast Asia, Kanaden Corporation has local subsidiaries in Thailand, Singapore and Vietnam, The company has been building up solution offerings by distributing factory automation (FA) equipment and systems. Both based in Thailand, Kanaden (Thailand) Co., Ltd. handles sales while FACOM-KD (Thailand) Co., Ltd., a joint venture company, handles automation systems. Kanaden also established in July 2020 Kanaden TRADING (Thailand) Co., Ltd., a local subsidiary that procures materials and sources out new materials.

Amid the COVID-19 cases in the country, the Thai government sets as priority industries, next-generation vehicles and smart electronics. Its long-term growth vision is to join the ranks of industrially advanced nations in the next 20 years.

Jun Minemura, Managing Director of Kanaden (Thailand), says, “Although Thailand is also battling the COVID-19 pandemic, our company’s business has been steadily expanding. While the shortages of semiconductors and electronic components are a concern, we intend to expand our business by promoting solutions with high added values.”

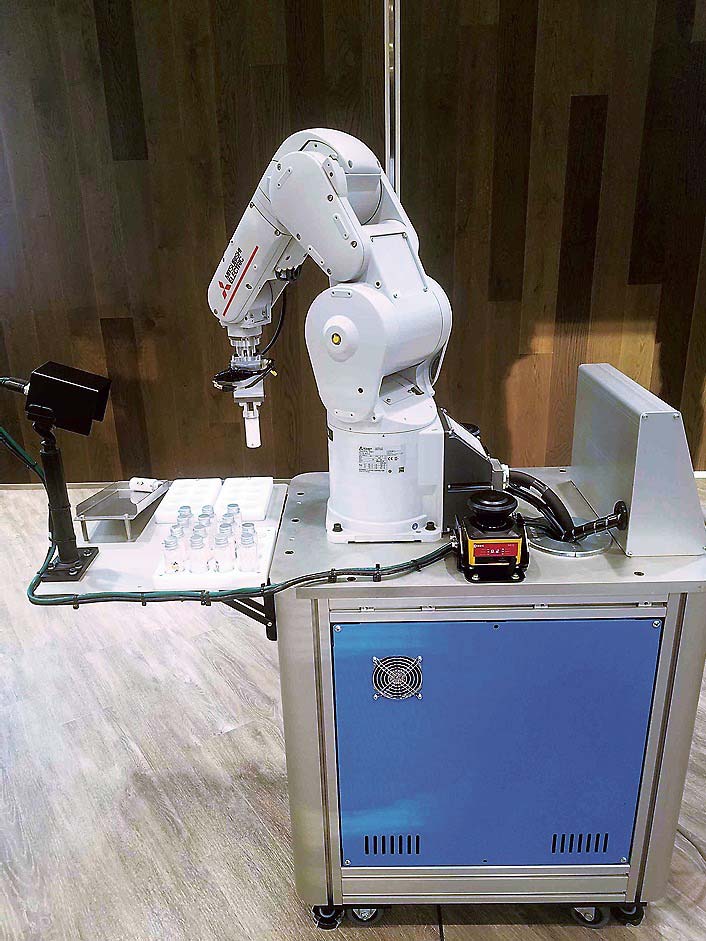

The company deploys the KaRy portable robot system developed jointly with Office FA.com Co., Ltd. in Japan, on top of other solutions. The company also pitches KaRy for use in training on the installation of robots and as a teaching material at universities.

Iida Electronics: Expand EMS Business

Iida Electronics (Tsusho) Co., Ltd. has expanded its electronic manufacturing services (EMS) business at its wholly-owned subsidiaries in Thailand and Myanmar.

Atsushi Moriyama, Director of Iida Electronics (Tsusho), says, “We have been deploying business leveraging our integrated system from component procurement with diverse procurement capabilities, mounting of printed circuit boards (PCBs) to assembly. Amid recent shortages of semiconductors and electronic components, our company’s integrated system received high acclaim and the number of outsourcing cases has been increasing. At the Thai Plant, outsourcing from diverse fields, including consumer electronics, electronic components, office automation equipment, automobiles and communications fields, has been increasing. Its EMS business has been steadily expanding as well.”

The Thai Plant mainly performs mounting of PCBs and bonding of liquid crystal panels in the ISO14644 Class 7 clean room. It aims for a manufacturing level at par with Japan quality. The clean room is installed with FUJI Corporation’s NXTⅢ high-density mounting machine. It operates seven lines with a total production capacity of 500 million shots per month. It receives increasing outsourcing requests mainly from customers in communications-related equipment.

Iida Electronics (Tsusho) has consolidated the PCB mounting business of the Dongguan Plant to the Thai Plant. It positions the Thai Plant as a global hub for business expansion. The company intends to build up a business that uses originally developed bonding equipment for LCD panels and other devices.

Ryoyo Electro: Tap Malaysia Base

Ryoyo Electro Corporation has established Ryoyo Electro (Malaysia) Sdn. Bhd. in Kuala Lumpur, Malaysia through Ryoyo Electro Singapore Pte., Ltd. It has been in operation since Oct. 2019. This is part of the company’s efforts to strengthen its business in Southeast Asia. The company opened the representative office in Kuala Lumpur in 2011 in collaboration with Ryoyo Electro Singapore.

Many Japanese manufacturers are operating in Malaysia. Ryoyo Electro (Malaysia) strengthens Ryoyo Electro’s sales system and improves customer support as a marketing base in Malaysia and other countries in Southeast Asia.