ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Mitsubishi Electric to Up Web Support for LV100-Powered Inverter

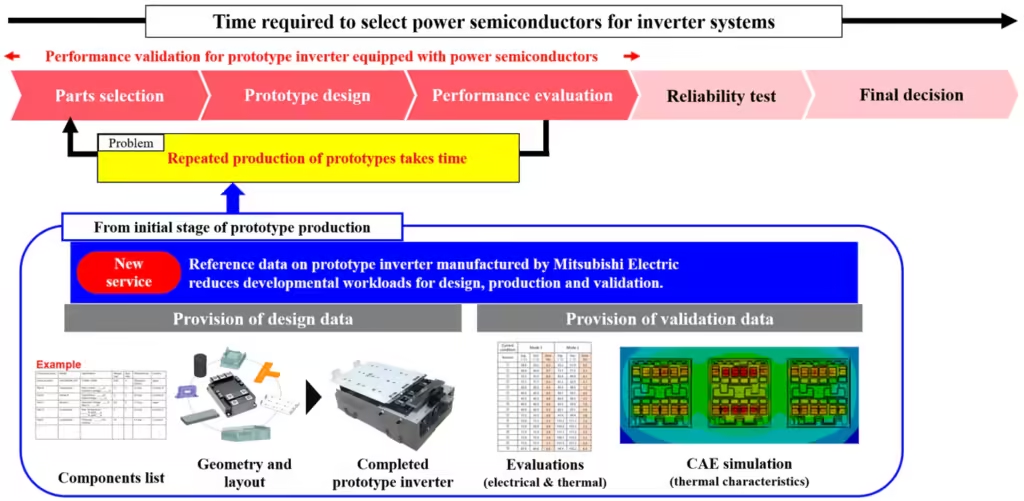

Mitsubishi Electric Corporation will launch a web-based service on June 28 to provide data on the design and validation of a proprietary prototype inverter*. Particularly, it features a module containing three LV100 insulated gate bipolar transistors (IGBTs).

The new service aims to help customers accelerate their development of high-power inverters. They suit applications such as photovoltaic power-generation systems.

Customers involved in developing prototype inverter systems with LV100 packages are expected to use reference information provided by the service. Primarily, these will reduce their design, manufacture and validation workloads. The company will display the service at PCIM Europe 2024 in Nuremberg, Germany from June 11 to 13.

Prototype Inverter Featuring Three LV100 IGBTs

The prototype inverter includes a package of three parallel LV100 industrial IGBTs in a module measuring 100×140mm, typical of those used in high-power inverter systems.

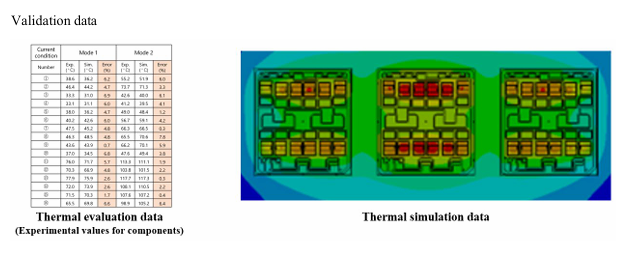

Specifically, the reference data will include design data, such as geometry, component layout and electrical circuitry, as well as evaluation data such as temperatures, short-circuit protection, current balance and computer-aided engineering (CAE) validation results.

*Redeveloped based on the prototype inverter co-developed by Tamura Corporation, National Taipei University of Technology (NTUT) and Mitsubishi Electric Corporation.

Details of New Service

Prototype inverter components list and design information will reduce design workload

The service will provide a list of components for Mitsubishi Electric’s proprietary prototype inverter and design information. Basically, it covers parts configuration, electrical circuitry, etc. Thus, it will help reduce the burden of parts selection and design.

This module is widely used as a standard package for power semiconductor modules in high-capacity inverter systems. Thus, information provided by the service will contribute to the design of inverter systems using the same package for other applications.

Prototype inverter validation data reduces design, manufacture and evaluation workloads

Validation data based on CAE analysis and evaluation data on temperatures, short-circuit protection, current balance, surge voltage, etc. for power modules, which tend to be burdensome when developing high-capacity inverter systems, helps to reduce design, manufacture and validation workloads.

The reference validation data will also contribute to design and manufacture accuracy for prototypes developed according to each customer’s design standards.

Power ICs Boost Decarbonization

The demand for power semiconductors as key devices that can contribute to decarbonization is growing rapidly.

However, selecting the right device is a difficult process involving complex designs for heat dissipation, current balance, fault protection and insulation. As a result, there is a need to devote much time to the design, manufacture and evaluation of inverter prototypes.

-07 June 2024-