ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

LG Innotek Turns to AI for Better Camera Modules

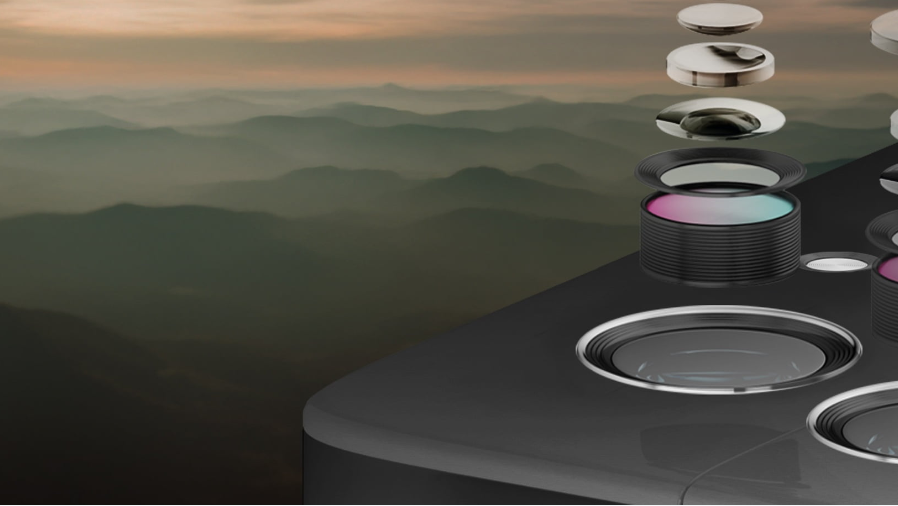

LG Innotek has announced it successfully lowered the defect rate of high-spec camera modules by using AI technology.

With the proliferation of AI, LG Innotek is solidifying its position as the top global manufacturer of camera modules. In line with this, it streamlines the production of intricate components and reduce the need for lengthy ramp-up processes.

LG Innotek aims to enhance profitability through the implementation of advanced ‘Industrial AI’ technology. Also, it aims to improve cost competitiveness by stabilizing the initial yield.

Developing AI Process Recipe

‘AI process recipe’ solves the initial yield, which determines profitability and customer confidence.

Low production output in the initial phases of large-scale manufacturing of valuable new products is a frequent problem in the manufacturing industry. Also, it poses a considerable obstacle.

Thus, manufacturers repeat simulations and test productions numerous times until they find the right process recipe capable of producing high-quality products. The longer this process takes, the higher the F-Cost (cost incurred to correct a defect after mass production); thus more mass production delays.

Failing to meet the delivery date results in a decrease in customer trust. Therefore, component manufacturers place so much importance on stabilizing the initial yield, sometimes even risking their business.

Generally, LG Innotek believes that the key to tackling this challenge is through AI. This leads them to start developing AI that can forecast process defects starting in 2021.

Specifically, AI examines the entire initial process and identifies where defects are likely to occur before they happen.

Also, AI uses defect prediction results to create a simulation that considers various factors in the process. Among them are the strength of the machinery, the speed of the conveyor belt, and the indoor temperature. By doing this, a process recipe that can reduce the defect rate to a minimum is developed.

Last year, LG Innotek used an ‘AI process recipe’ for the first time in the industry to manufacture a high-spec camera module.

Significantly Reduced Defect Rate

An AI trained on tens of millions of data points reduced the defect rate of key inspection items by up to 90%.

Consumers prefer smartphones that are slim, lightweight, and offer enhanced performance. Thus, the thickness and size of the high-spec camera module could be reduced in line with this trend.

The manufacturing process becomes increasingly sophisticated as the camera module specifications become ultra-slim with high specifications. The camera module undergoes numerous stages of highly precise processes.

Previously, when a flaw was found during performance testing at the start of camera module mass production, it would take over 72 hours to create a new process recipe. Nevertheless, by implementing the ‘AI process recipe’, the process has been condensed to just 6 hours. This is no longer an issue due to the elimination of the need to repeatedly make recipe corrections and sample productions based on an engineer’s experience.

The defect rate in major inspection items was previously high. Now, it is lower by up to 90% thanks to the implementation of the ‘AI process recipe.’

According to a spokesperson from LG Innotek, they utilized AI to analyze tens of millions of data points on the camera module process to develop the best possible manufacturing method. Additionally, they mentioned that these data resources will be crucial in enhancing the company’s quality standards.

Taps AI for Semiconductor Substrate Process

Effective in enhancing cost competitiveness…”AI will be applied to semiconductor substrate process”

LG Innotek was able to stabilize the initial yield of camera modules and significantly enhance cost competitiveness by utilizing ‘AI process recipe’.

In the first quarter, LG Innotek’s operating profit increased by 21.1% from the previous year to reach US$128 million. It is analyzed that the innovation of the camera module process through the ‘AI process recipe’ also played an important role in enhancing cost competitiveness.

LG Innotek plans to extend the use of the ‘AI process recipe’ to semiconductor substrates during the current year. Additionally, it will broaden the range of products that can benefit from increased yield with AI.

CEO Moon, Hyuksoo said, “As we strive to advance digital manufacturing methods with the help of AI technology, our goal is to establish ourselves as a ‘top global technology innovation company’, assisting our customers in achieving a leading global company by excelling in technology, quality, and manufacturing capabilities.”

-13 June 2024-