ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

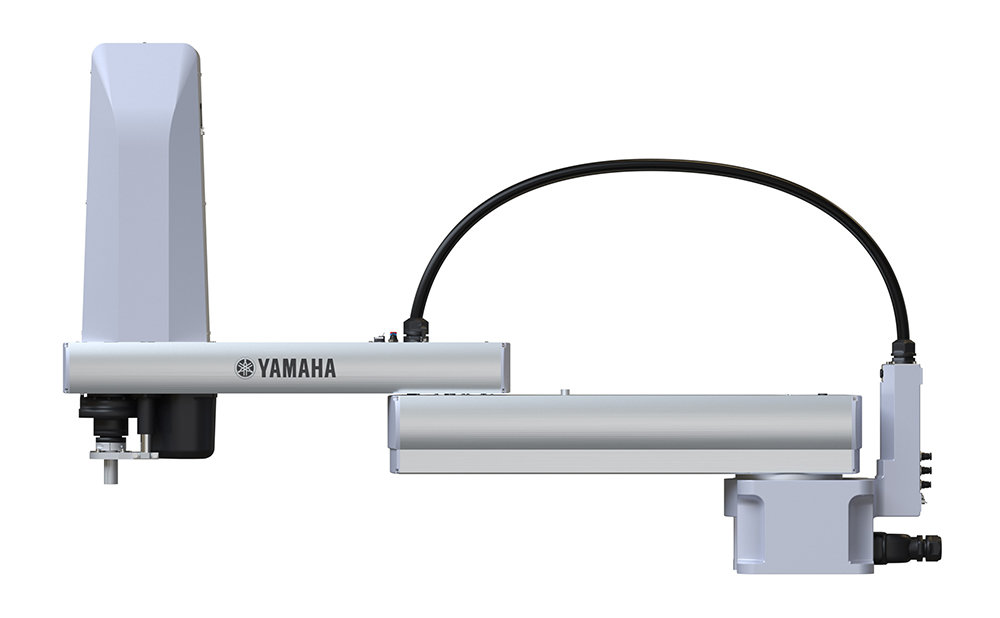

Innovative Yamaha Tech to Make Way in New SCARA Robot

Yamaha Motor Co., Ltd. is its SCARA robot YK-XG series with the addition of the YK1200XG model. In addition, it will launch it alongside the RCX341 dedicated controller starting October.

The YK1200XG SCARA robot suits assembly and transport of large and heavy objects. Moreover, it features a 1,200mm arm length and achieves industry-leading cycle times with a maximum payload of 50kg.

The RCX341 dedicated controller, while maintaining the compact design of the previous RCX340. Moreover, it also increases the maximum output current. Thus, providing stable support for the high-speed transport of heavy loads by the YK1200XG.

The YK-XG series SCARA robots have a completely beltless structure, significantly reducing lost motion. At the same time, maintains high precision over extended periods.

Furthermore, the direct connection of the end rotational axis to the reducer allows for high permissible inertia on the R-axis. Thus, enabling high-speed operation even with offset workpieces. With the addition of the YK1200XG, the lineup now spans a wide range, from 120mm to 1,200mm arm lengths, placing it among the industry’s top-class offerings.

Market Background

Yamaha Motor is a comprehensive small robot system supplier offering a wide range of products. Specifically, these are linear conveyors, single-axis robots, SCARA robots, vision systems, and controllers for automated production lines. Leveraging the Company’s extensive lineup, it strives to enhance efficiency and quality in increasingly complex, diverse, and fast-paced production environments. Thus, providing the best solutions to meet our customers’ diverse needs.

The YK1200XG can meet the growing global demand for automotive battery manufacturing processes, driven by the rise of electric mobility. As a result, it combines high operational performance and cost-effectiveness. Therefore, making it ideal for handling weights of 20 to 50kg.

YK1200XG Main Features

High Speed

The YK1200XG, with an arm length of 1,200mm and a maximum payload of 50kg. It achieves one of the industry’s fastest standard cycle times for SCARA robots. In addition, Yamaha Motor also emphasizes tact time in practical applications.

By reviewing the reduction ratio and the maximum motor rotation speed, Yamaha Motor has significantly increased the maximum speed compared to previous models.

Additionally, the direct connection of the end rotational axis to the reducer ensures an overwhelmingly higher R-axis allowable inertia moment than typical structures that use reducers and belts, enabling high-speed operation even with offset workpieces.

Internal Structure Realizing High Rigidity

The ZR-axis direct coupling structure enables a completely beltless design. The beltless structure significantly reduces lost motion. It can be used for long periods without maintenance, eliminating concerns about belt damage, stretching, or aging.

RCX341 Main Features

High Output with Compact Design

Based on the RCX340, the RCX341 has advanced functionality that enables high-level facility construction. Moreover, the Company has reviewed the internal structure of the controller and the inverter circuit.

While the casing size remains the same at W355mm x H195mm x D130mm, the maximum output current has been increased. This supports high-speed handling of heavy objects.

The regenerative unit has also been designed to match the controller’s height and depth at W80mm x H195mm x D130mm, considering installation within the control panel.

12 September 2024