ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

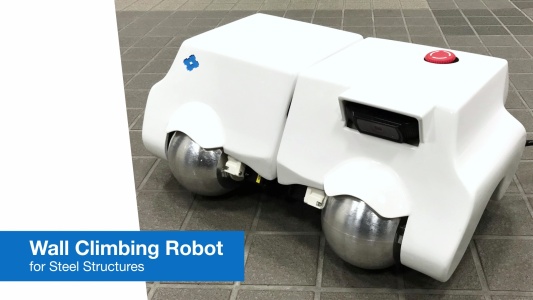

Sumitomo’s Latest Robot Features Magnetic Adhesion

Sumitomo Heavy Industries, Ltd. has developed a novel robot capable of traveling over curved steel walls by magnetic adhesion. The achievement is part of a robot development project at its Technology Research Center. Specifically, the project aims to automate various manufacturing tasks at industrial sites. The development was achieved under Challenge Program*1 launched in FY2018.

Wheeled robots with magnetic adhesion are well known in manufacturing and maintenance of large steel structures like ships and industrial facilities. Most conventional wall climbing robots are designed for flat surfaces. To adapt such robots to curved surfaces, it is necessary to make the robot smaller than the curvature of the surface. On the other hand, one can design the robot to fit a particular surface shape and traveling direction. Thus. these robots are limited in the range of surfaces they can travel on, the tasks they can perform, and the types of tools they can mount.

Magnetic Adhesion Technology

Particularly in this project, Sumitomo invented a novel spherical wheel containing a magnet that can be rotated around two axes. Using this design, it has developed a robot that can adapt and travel over curved surfaces, which were not possible with conventional robots. In addition to traveling over curved walls, the new robot can also easily attach and detach from walls by changing the magnetic force direction. Additionally, it can climb over corners without the need of any complicated controls.

In manufacturing of large steel structures, tasks like welding at heights and on curved surfaces are difficult to automate. They also require advanced skills. The newly developed robot can be used for such tasks. Moreover, it can reduce the physical burden on workers, thereby creating safer and smarter next generation manufacturing sites.

This new technology is based on a mechanism presented at IEEE ICRA*2 2020. Since then, the company has improved the robot design and performance, such as magnetic adhesion force.

At present, Sumitomo is developing practical applications of the robot in inspection, cutting, and arc welding at manufacturing sites.

The company will continue fostering the spirit of challenge in its employees. It will contribute towards development of a sustainable society by creating new technologies.