ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Asahi Kasei, Aquafil Ally on New 3D Printing Material

Asahi Kasei Corporation, a Japanese technology company, recently signed a memorandum of understanding (MOU) with Aquafil S.p.A., an Italian manufacturer of polyamide 6 (PA6). Primarily, the two companies agreed to develop a novel material for 3D printing (3DP) applications utilizing Aquafil’s ECONYL® Polymer chemically recycled PA6 and Asahi Kasei’s cellulose nanofiber (CNF), with the support of ITOCHU Corporation, which has made a capital investment in Aquafil.

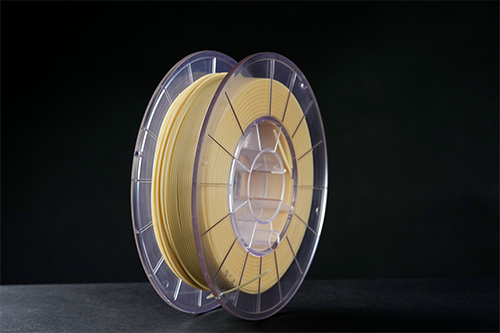

Particularly, the pellets or filaments of this compound achieve superior formability and strength. These make them suitable for use in automotive and aeronautical applications.

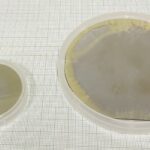

Particularly, ECONYL® Polymer is a chemically recycled PA6 derived from post and pre-consumer waste. Utilizing polyamide waste such as used fishing nets, old carpets, industrial waste and so on, the material is first depolymerized into monomers, and then re-polymerized into ECONYL® Polymer chips.

Meanwhile, Asahi Kasei’s CNF is made from cotton linter. It features high heat resistance and network-forming ability. Furthermore, CNF has superior material recyclability compared to glass fiber. Particularly, the new CNF/ECONYL® Polymer compound features excellent formability and strength, especially in 3DP usage. Asahi Kasei sees great potential in high-performance applications mainly in the automotive and aeronautical fields.

Asahi Kasei plans to begin trial sales of filament of the new compound material in countries in the European Union, in the United States, and in Japan in Q3 2025. The new material will be showcased at the upcoming Fakuma (15-19 October, Germany), Sustainable Material Expo (29-31 October, Japan), and Formnext (19-22 November, Germany).

-10 October 2024-