ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

DIC and Unitika's New PPS Film Suits mmWave PCBs

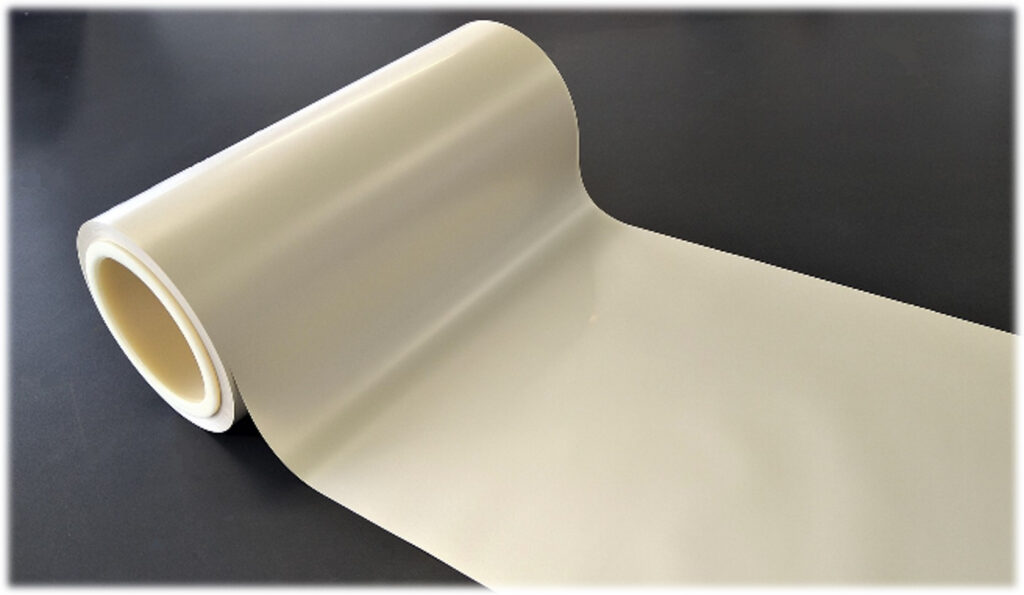

DIC Corporation has developed a new specialty polyphenylene sulfide (PPS) film in collaboration with Japanese firm Unitika Ltd. that suppresses transmission loss at high frequencies. Particularly, this product’s low dielectric properties make it suitable for use in a key for millimeter-wave printed circuit boards (PCBs) compatible with next-generation communications devices and for millimeter-wave radar. Also, this new PPS film has already been evaluated by a number of electronics materials manufacturers. Preparations are currently being made to commence commercial production.

Mainly, conventional high-frequency flexible PCBs used in smartphones and small electronic devices are fabricated by bonding layers of liquid crystal polymer (LCP) film and copper foil. Particularly, LCP creates in an uneven film–copper foil adhesive interface, a cause of higher transmission loss. Next-generation communication devices use the millimeter-wave frequency band (30 to 300GHz). Thus, they require materials with low dielectric properties, which minimize transmission loss.

This time, the specialty PPS film developed by DIC and Unitika combines the former’s proprietary PPS polymerization and compounding technologies with Unitika’s film manufacturing technologies. This new film maintains the low moisture absorption, as well as the flame and chemical resistance, of PPS resin. At the same time, it delivers outstanding low dielectric properties, dimensional stability, reflow resistance and uniformity of thickness required for high-frequency PCBs.

Also, this product demonstrates stable dielectric properties in high-temperature environments and at a wide range of frequencies (10 to 1,000GHz). This performance feature is difficult to achieve with LCP or other common films. As a result, it is expected to be adopted for a wide variety of applications, from smartphones to automobiles.

Moreover, this new film boasts excellent adhesiveness with different materials. This means it is compatible with a broad range of flexible copper clad laminate (FCCL) processing methods. Among them, include sputtering and plating, as well as lamination with an adhesive. The sputtering and plating method delivers a smooth adhesive interface that achieves lower transmission loss than commonly used films, including LCP or fluoropolymers.

The DIC Group is contributing to digitalization by developing functional materials that anticipate emerging needs in the development of infrastructure for next-generation communications. Ths include 5G/6G, and generative AI, which are expected to see accelerated demand in the years ahead.

-10 October 2024-