ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Intel Tracks Chip Tech in New Roadmap Update

Intel Chief Executive Officer Lip-Bu Tan took the stage April 29 (Calif., U.S. time) for the first ever Intel Foundry Direct Connect as he outlined the company’s progress in core processes and advanced packaging technologies.

During his speech, Tan drew the company’s priorities and drives for the next phase of its foundry strategy. Specifically, Tan announced that manufacturers are already engaged with its customers for the testing of the latest 14A process (1.4nm) technology.

“Intel is committed to building a world-class foundry that serves the growing need for leading-edge process technology, advanced packaging and manufacturing,” said Tan.

In addition, Tan said, “Our No. 1 job is to listen to our customers and earn their trust by creating solutions to enable their success. The work we are doing to drive an engineering-first culture across Intel while strengthening our partnerships throughout the foundry ecosystem will help us to advance our strategy, improve our execution and win in the market long term.”

Intel’s 14A, 18A Process Nodes

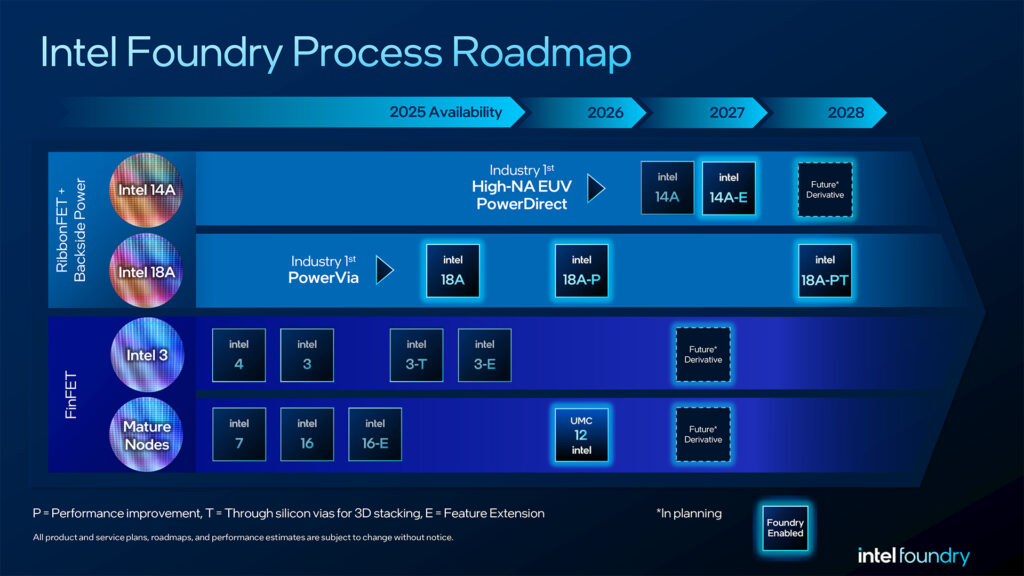

Intel first announced its 18A node in 2021 and currently, Tan said this process node, equivalent to 1.8nm, has already entered risk production, marking its first low-volume production. The 18A node will have high volume production towards the end of this year.

The 18A was the latest advancement in Intel Foundry process technology, featuring RibbonFET gate-all-around (GAA) transistors and industry-first PowerVia backside-power delivery network. Specifically, the PowerVia provides optimized power routing on the back of the chip to improve performance and density. On the other hand, the RibbonFET offers better transistor density and faster transistor switching in a smaller area.

Tan announced at Intel Foundry Direct Connect event that the 18A will have two variants. First is the 18A-P, designed to deliver enhanced performance to a broader set of foundry customers and early wafers are on fab now. On the other hand, the second variant, Intel18A-PT, can be connected to top die using Foveros Direct 3D with hybrid bonding interconnect pitch that is less than 5mm. Specifically, Tan said 18A-PT is designed for AI and HPC customers building next-generation 3DIC designs.

Naga Chandrasekaran, Intel Foundry chief technology and operations officer, admitted that the R&D focus has been with 18A for the past two years because it “is facing ups and downs”. However, with new technologies, Intel continues to make progress with production likely to happen towards later part of 2025.

Meanwhile, Intel’s 14A is the next-generation 18A and its first low-volume production is around 2027. Intel 14A will feature PowerDirect direct contact power delivery, building on the PowerVia backside power delivery technology in Intel 18A.

Intel said it will be the industry’s first High Numerical Aperture (High NA) EUV, enabling cost-effective printing of smaller process features.

What will make 14A even more special is it will have Turbo Cells, Intel’s boosted cell technology that will further enhance speed when paired with RibbonFET 2. Accordingly, Turbo Cells allows designers to optimize a mix of more performant cells and more power-efficient cells within a design block. Thus, enabling a more tailored balance between power, performance, and area for target applications.

Other Announcements

Tan also announced that the company’s Fab 52 in Arizona, United States, has successfully marked its first wafer processed through the facility. Thus, demonstrating progress in domestic manufacturing of leading-edge Intel 18A wafers.

Accordingly, Intel 18A volume production will begin in Intel’s Oregon fabs as Arizona manufacturing ramps later this year. Tan emphasized all research, development, and wafer production of Intel 18A and Intel 14A will all happen in the United States.

30 April 2025