ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Alliance to Make New Mark in IC Inspection, Metrology

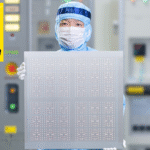

Kioxia Iwate Corporation will be evaluating the the joint inspection and metrology technology that Nagoya University startup Photo electron Soul Inc. and the Nagoya University Amano-Honda Laboratory jointly developed. Specifically, the technology will be for advanced semiconductor manufacturing.

During the critical field test, Kioxia Iwate will evaluate and verify the benefits of adopting this advanced technology to improve overall manufacturing yield by enhancing defect detection and root-cause analysis within live inspection and metrology processes.

Innovative Inspection, Metrology

3D flash memory is a sophisticated device characterized by a memory cell stacked structure. Kioxia has been developing advanced inspection and metrology techniques that tackle the manufacturing challenges posed by increasing layers and higher integration. The two key technologies (photocathode e-Beam inspection and metrology) under evaluation by Kioxia enable critical functions like non-contact electrical inspection, defect detection, and profile measurement in deep regions of high-aspect-ratio structures, which are difficult to achieve with traditional methods.

These functions are unique to GaN-based photocathode e-Beam technology, including DSeB (Digital Selective e-Beaming) and YCeB (Yield Controlled e-Beaming). They allow innovative inspection and metrology through selective e-Beam radiation and real-time control of beam intensity, thus preventing any beam misalignment.

“This evaluation provides a great opportunity for us to prove that our inspection and metrology technology is unmatched. No other inspection tool supplier has yet commercialized it, and it is ready for production in a semiconductor manufacturing environment,” said Takayuki Suzuki, CEO of PeS. “We are confident that this will become a core technology for Kioxia, enabling them to significantly enhance their advanced inspection and metrology capabilities and outperform rival NAND flash producers in Korea and the US.”

03 September 2025