ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Canon ITS Launches AI Inspection Platform

Canon IT Solutions Inc. has launched an artificial intelligence (AI) inspection platform Visual Insight Station. It specializes on visual inspection and non-destructive inspection in the manufacturing process.

AI Replaces Manual Inspection

In recent years, the performance of industrial cameras has improved, and practical use of AI has advanced. Under these circumstances, major companies have been implementing operational reforms to reduce labor costs and improve production efficiency. In the manufacturing industry, manual visual inspection is being replaced with AI.

AI Inspection Platform

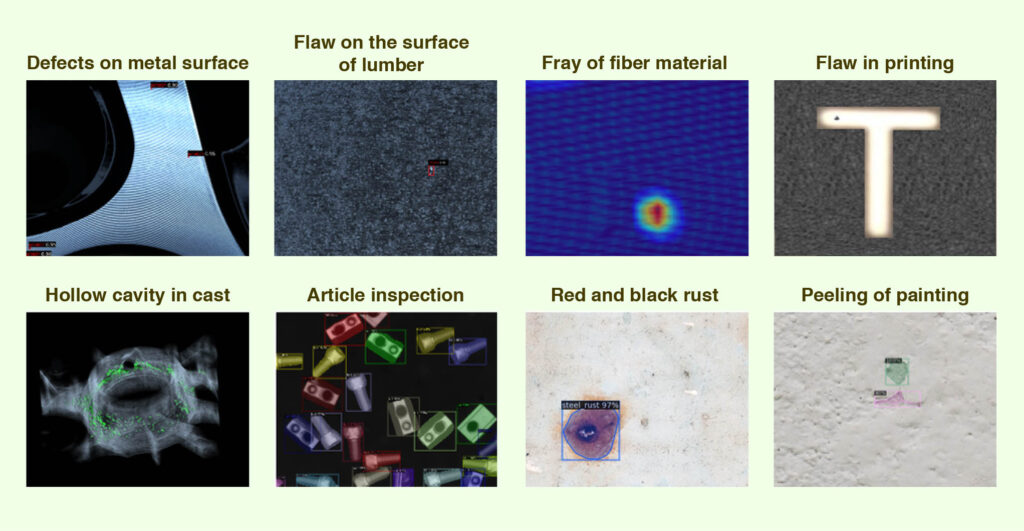

Meanwhile, inspection targets vary in terms of shape, material, size, and defects. This process makes recognition accuracy difficult using existing pre-learnt AI models. Therefore, it is effective to construct a shooting environment that meet the characteristics of an inspection target. Also, introducing a dedicated AI model, which uses images shot under the environment, is also an effective method.

To solve these issues faced by the manufacturing industry, Canon IT Solutions (Canon ITS) has started offering Visual Insight Station, an AI inspection platform, which provides one-stop support to manufacturers from the development of AI inspection system to operation. It is done based on findings and know-how of AI (deep learning) the company has accumulated through many proof of concepts (PoCs).

The platform automates visual inspection to detect minute defects on the surface of an object taken by a high-resolution camera. It also performs non-destructive inspection to detect minute defects inside the object from the image generated by computerized tomography (CT) system using AI.

Using the platform as the core of users’ AI inspection system and by combining it with imaging devices, such as a camera and lighting, a flexible AI inspection system that matches the user’s operation can be built.

Users can perform additional learning and maintenance of AI after the introduction of the system. Advancing the AI model adding inspection targets and allowing it to accommodate changes of the inspection environment is possible. These capabilities enable the maintenance of AI’s recognition rate at high level. They also contribute to improved inspection accuracy and productivity in the manufacturing industry.

Provide One-Stop Solutions

Canon ITS has provided AI and image processing solutions that combine its software development technology, image processing technology it has nurtured in the development of Canon products, and image recognition technology using AI to various manufacturing sites. The company intends to continue providing one-stop solutions optimum to users’ needs. It leverages manufacturing (monodzukuri) expertise and advanced technologies it has nurtured in research and development over many years.