ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yokogawa’s Omega Simulation Launches new Digital Twin

Omega Simulation Co., Ltd., a subsidiary of Yokogawa Electric Corporation, has revamped its OmegaLand plant operation simulation environment as the OmegaLand V4 dynamic digital twin platform. At the same time, it has also released the first version, V4.1.

Development Background

The plant operation environment has grown more complex in recent years due to intensified market competition, equipment aging, labor shortages, cybersecurity risks, stricter regulations, and supply chain changes.

As industries enter a period of major transformation, expectations are rising that the use of AI and other advanced technologies will lead to autonomous operations.

However, this will require the clear identification of issues and a phased transition in which risks are evaluated and optimization is performed. In turn, informed decisions will need to be made on the introduction of new technology.

OmegaLand V4 Concept

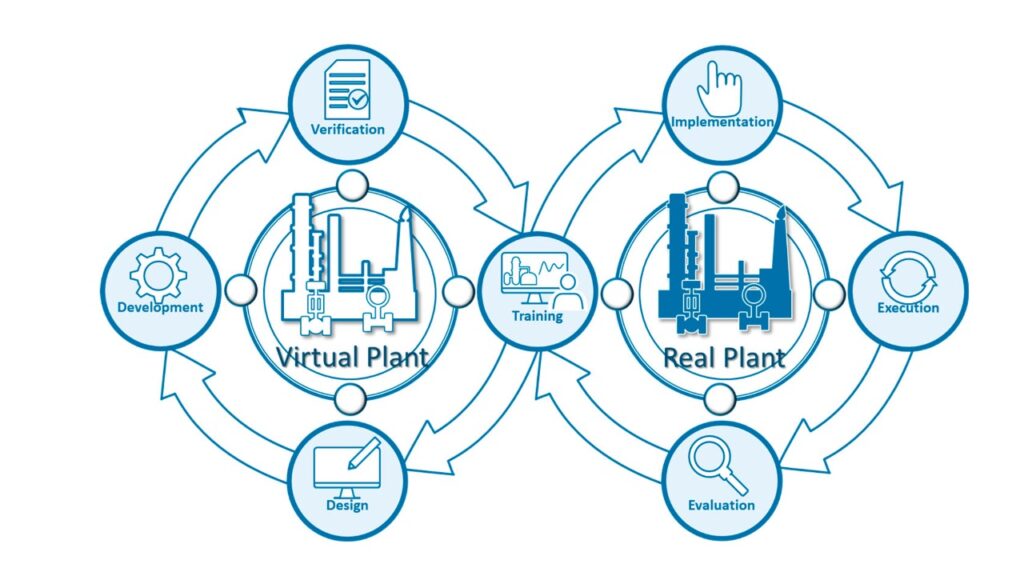

OmegaLand V4 is designed as a dynamic digital twin platform that maximizes the return on investment in building dynamic models and supports the autonomous operation of plants.

By strengthening integration with Yokogawa’s CENTUM VP control system, dynamic simulation technology – traditionally used offline – can now be consistently applied not only to operator training but also to the development, verification, implementation, and evaluation of AI models and other advanced control solutions that contribute to the autonomous operations of plants.

Furthermore, even as operational autonomy advances and human intervention decreases, the platform will provide a framework that combines operational risk assessment with a dynamic simulator. Therefore, enabling verification of hazardous scenarios and the formulation of countermeasures.

Main Features of OmegaLand V4.1

In line with the OmegaLand V4 concept, basic functionality and integration with control systems have been strengthened as follows:

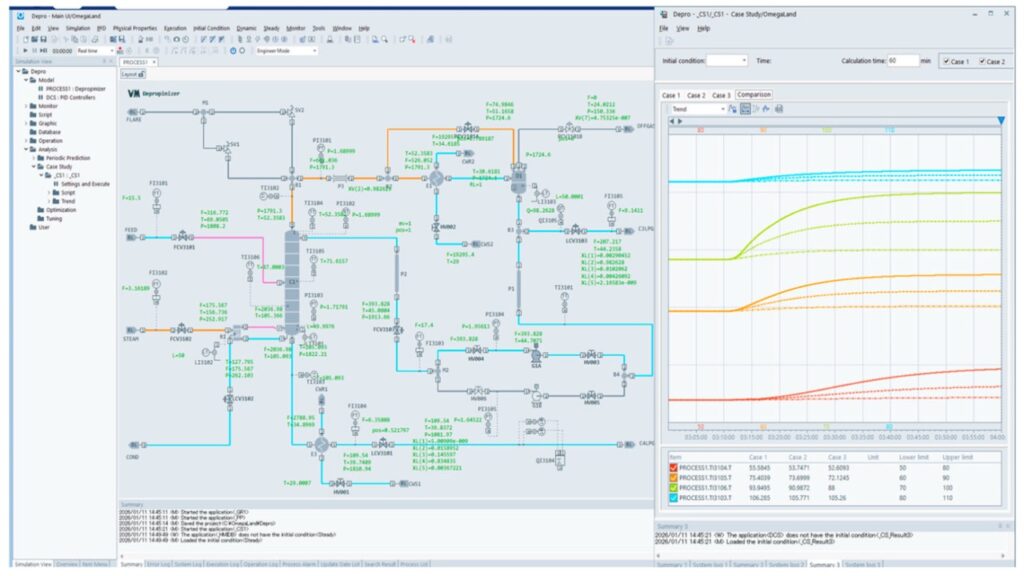

Enhanced case study functionality

A case study function has been enhanced that allows users to test “what if” scenarios in a virtual plant environment. For such purposes, as saving energy and improving efficiency, users can register up to ten scenarios and simultaneously compare up to three test cases to evaluate changes in operating conditions or control procedures. Thereby, improving testing efficiency and reducing costs.

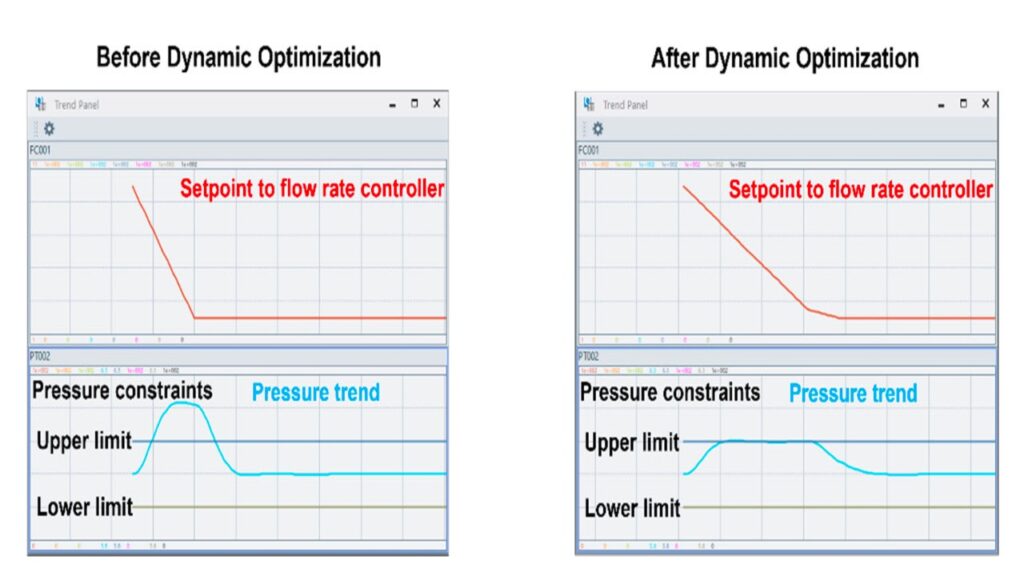

Optimization function for efficient, adaptive operations

Based on conditions such as plant operation control values and product specifications, a function is provided that helps eliminate waste in the use of raw materials and energy by identifying optimal operating conditions.

Also, when changes are made in operating conditions, it presents patterns that can reduce the load on equipment and ensure safe and efficient transitions. Rather than optimization at a single point in time (static optimization), sustained optimal operation (dynamic optimization) is achieved by flexibly responding to load fluctuations and changes in the external environment.

Enhanced integration with CENTUM VP

OmegaLand Plant Tracker, which visualizes the status of a plant by giving online and real-time access to information such as changes in plant operations and operator inputs, has been added as a new solution.

In addition, the simultaneous synchronization of simulations with Centum VP improves the accuracy of the simulation environment employed to conduct operator training, risk assessment, and pre-operational reviews.

Note: This material has been provided by Omega Simulation/Yokogawa Electric