ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

FUJI to Soar Next-Gen Mounting in AI Era

FUJI Corporation has been in the forefront of developing equipment technology for mounting next-generation ultra-small electronic components. Recently, the company has succeeded in mounting *016008M (0.16×0.08mm) components on a board, an industry first, using its NXTR electronic component mounting robot.

In recent years, the shift to “edge AI” has been accelerating. The industry is moving towards an era where all kinds of devices, such as smartphones, wearable devices, and even medical and healthcare devices, autonomously analyze information.

With this trend, the number of mounting points of electronic components is increasing further as more electronic devices become more sophisticated. Moreover, further miniaturization and density of electronic components has become indispensable and has become a crucial technical issue.

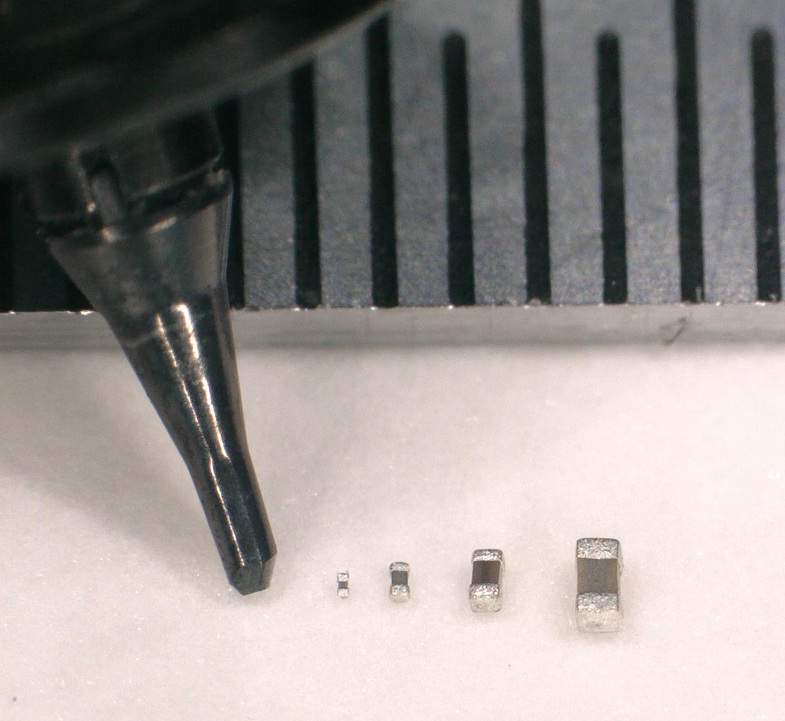

Size Comparison of 016008M Components and Practical Components 0201M (0.25×0.125mm), which has been considered the smallest standard among the electronic components currently in practical use, will eventually reach its limit in pursuing further density in the pursuit of more electronic functions in a limited board space.

Therefore, the industry is developing 016008M parts, which is the next generation standard. For 016008M components, the mounting area is approximately halved compared to the 0201M size, allowing for higher-density circuit design.

First 4 Key Control Technology

FUJI has provided high-speed, high-precision mounting machines that achieve stable handling of extremely small parts. By further evolving the following four key control technologies, the company has realized the world’s first board mounting of 016008M components.

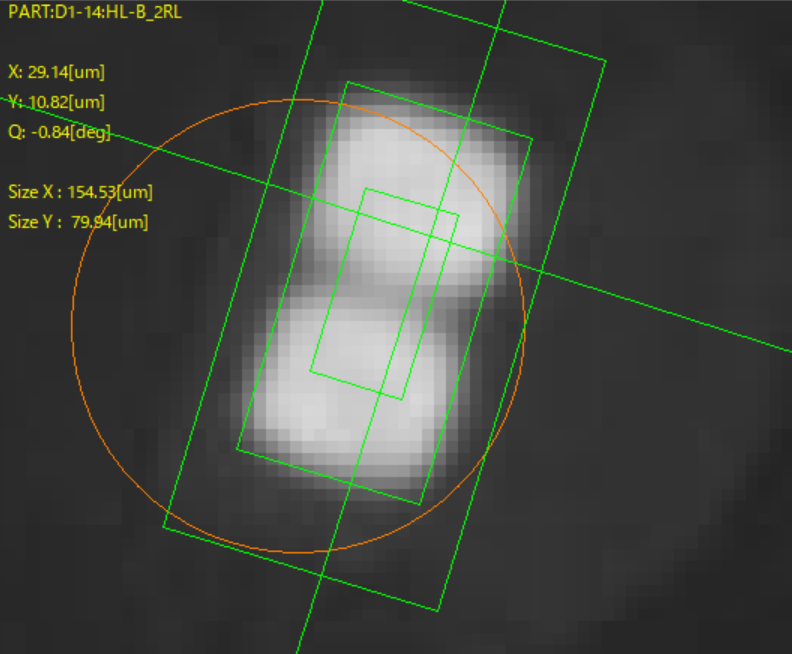

1. Component Handling Posture Recognition Detects the tilt and posture of extremely small parts in real time to achieve optimal handling.

2. High-precision part pick-up control Suppresses the effects of adsorption misalignment and static electricity, and realizes stable part pick-up.

3. Loading Superfine Control Precise load control that allows loading at a pressure that does not damage the smallest parts.

4. Ultra-high-precision onboard positioning control Nano-level position correction achieves the industry’s highest level of mounting accuracy.

Total Solution for Next-Generation Ultra Small Parts

016008M Mounting of components up and below requires a high degree of optimization of the entire assembly process, not just the assembly process, including board design, solder material, stencil mask, reflow, and inspection.

FUJI is deepening cooperation with partner companies not only to develop equipment technology for mounting robots, but also to build a total process solution that includes these production materials and auxiliary materials, and will lead the competition for the miniaturization of electronic components to a new stage for the full-fledged arrival of the edge AI era.

16 January 2026