ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Solder Method Fosters Carbon-Neutral Mounting

For a carbon-neutral mounting, Senju Metal Industry Co., Ltd. (SMIC) has developed a new solder method that uses low-temperature solder. The company eyes to extensively promote the newly developed method and products to the mounting industry.

Tomohide Hasegawa, Representative Director and Executive & Operating Officer at SMIC noted customers’ growing interest in carbon neutrality. “Solders with low melting points improve solder processes in various levels. (These include) streamlined mounting and power efficient soldering bath. These measures contribute to carbon neutrality.”

“SMIC gives strong emphasis on the superiority of low-temperature solders. We have developed the manufacturing method, solder bath, and solder products for DIP method flow soldering. This is compatible with low-temperature solders. We will propose this method and related products widely to players who have an eye on carbon neutrality.”

Environment-Friendly Portfolio

Previously, mounters employed solder alloys that use tin (Sn) and lead (Pb) as base materials. The use of Pb has immense impact with the environment. Because of this, the Japan Electronics and Information Technology Industries Association (JEITA) endorsed in year 2000 the use in Japan of SAC305 standard. The standard promotes tin (Sn)-silver (Ag)-copper (Cu) as alloy base materials. As such, home electric appliances and audio-video (A/V) manufacturers widely adopt the SAC305 standard.

In 2001, SMIC released the M705 solder product compliant with the SAC305 standard. Since then, the company has expanded its portfolio, including low-silver and silver-less products to cope with rising silver prices. The company also values high-reliability solder products that employ multi-composition in accordance with application. In addition, the company produces both flow and reflow soldering systems and offers jet soldering and stationary solder baths.

At the same time, the company has already brought to market low-temperature solders. They are the Sn-bismuth (Bi)-based L20 with a melting point of 139 ˚C and Sn-Bi-antimony (Sb)-nickel (Ni)-based L29 with a melting point of 140˚C.

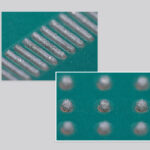

The use of Bi, indium (In), cadmium (Cd), and other elements decreases solder’s melting point to 183˚C or lower. Sn-Bi-based low-temperature solders generate a lot of dross when used in flow soldering. Dross is an oxidized solder that floats on the surface of solder bath and causes soldering defects in printed circuit boards (PCBs).

As a result, much dross adheres to PCBs, and could not guarantee reliability of mounted PCBs. This is the challenge that comes with ordinary flow soldering. Also, dross has been one of causes why using low-temperature solders for flow soldering is also an issue. Also, Sn-Bi alloys have low ductility, therefore, mass production of resin flux cored solder for rework, which is indispensable for flow soldering, has been difficult.

Carbon Neutral, New Solder Method

SMIC has tracked the path to overcome these challenges in flow soldering of low-temperature solders. First, the company succeeded in the development of a jet nozzle that reduces the generation of dross and the amount of dross that adheres to PCBs. It devised the jet stream of solder so that the jet nozzle reduces dross due to the entrapment of oxygen.

As it also reduces the risk of dross adhering to mounting boards, it ensures soldering performance higher than conventional solder (SAC305). It uses flux conventionally used for Sn-Ag-Cu alloys. The company also provides flux dedicated for low-temperature flow soldering (halogen-free rosin flux).

The company has also developed a technology to reuse the large amount of dross that generate in flow soldering inside the flow system. Low-temperature solders generate more dross compared with SAC305. Conventionally, it was necessary to recover dross stored in the solder bath once every hour. This takes time and leads to large amount of solder waste. The low-temperature flow soldering method SMIC developed enables the reuse of dross as solder in the solder bath without stopping production. This technique also reduces costs.

The company also sees prospects for mass production of 0.6 to 2.0mm low-temperature resin flux cored solders for rework. It has put a system in place to provide these technologies as general flow soldering technologies that consider customers’ manufacturing costs. Under this system, SMIC provides automatic soldering equipment and materials, such as low-temperature solder bars, fluxes, and low-temperature resin flux cored solders, to the manufacturing site.

Hasegawa said, “I hope that the proposal of our company’s low-temperature soldering is incorporated as one of environmental strategies in the electronics manufacturing industry.”