ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Productronica India: FUJI Smart Factory Concept

At productronica India 2021, which will take place from December 16 to 18 at Bengaluru International Exhibition Centre (BIEC) in Bangalore, India, FUJI Corporation will highlight its cutting-edge solutions and platforms that will change the landscape of smart factory.

NXTR Electronic Component Mounter

1. Zero placement defects

Maintains stable, high-quality placement using a newly developed sensing technology, which monitors the status of the machine in real time and controls the stress on parts and panels at the same time.

2. Zero machine operators

The newly developed Smart Loader completely automates part supply and changeover for next production according to the production schedule. This prevents short stops from part supply errors and similar issues that are caused by delays and mistakes during supply work.

3. Zero machine stops

NXTR continues the complete modularity concept the NXT has employed. Heads and other units can be exchanged without tools, making it possible to perform maintenance offl ine. Predictive maintenance is made possible through self-diagnosis, preventing sudden machine stops from affecting the production plan.

NXTR PM Solder Printing Machine

1. A high productivity rate can be maintained because solder cups for supplying solder paste can be set and cleaning paper can be exchanged during production.

2. Dual lane production is supported, so that a highly efficient dual lane production line can be formed in minimal space when used together with the NXTR electronic component mounter.

3. The printer is loaded with a new algorithm that supports determining the appropriate printing conditions to ensure that a stable amount of solder is transferred from the fi rst panel.

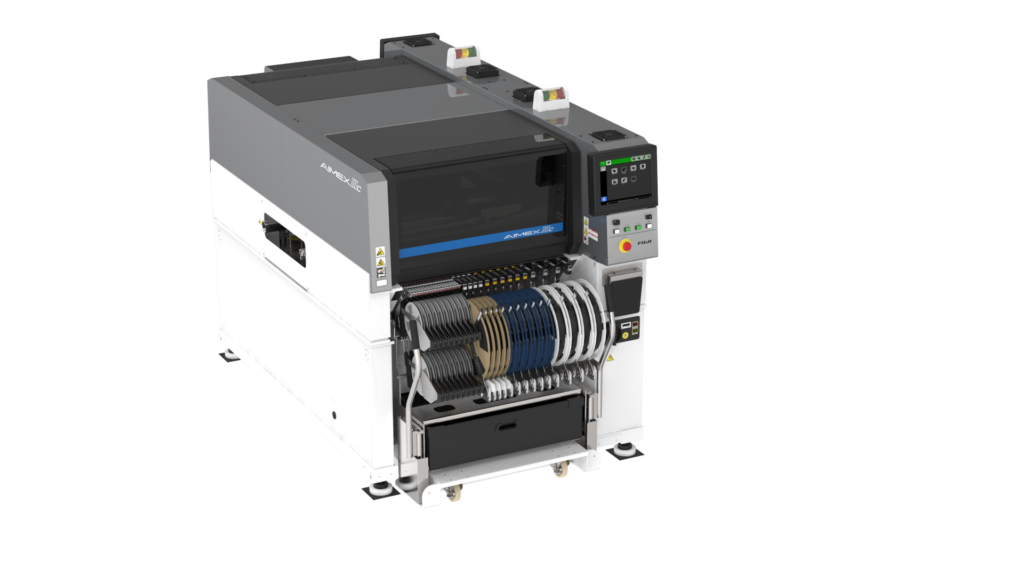

AIMEX IIIc FUJI Flexible Placement Platform

The placement platform suits compact high-mix production. The flexible placement machine supports high-mix, on demand production.

1. Can load a huge quantity of parts

The machine can set up to 130 reel parts. This reduces the number of times part changeover needs to be performed. It also fully supports large parts by being able to load tray parts on both sides.

2. Flexibility to place a wide range of parts

Places a wide variety of parts from 03015 up to 70×70mm in one machine with the DynaHead. It changes to the optimum tool and nozzles in one action.

3. Smoothly ramp up production

Automatic part data creation and on-machine editing using a large touchscreen panel supports ramping up new production and quick responses to sudden changes for programs.

4. Easy to introduce, compact design

Effectively uses fl oor space with the compact machine size of 280×346×656mm (L1×W2×H1).

SmartFAB Multi-Purpose Automated Fabrication Machine

A machine that automates insertion of electronic components which would usually be performed manually for high productivity, high quality, and labor savings.

1. Value added production

A wide variety of tools such as nozzles and chucks are equipped inside the machine as standard. Parts with various shapes can be supported by automatically exchanging these tools during production. By exchanging units designed based on the module concept, it is possible to load large odd-form parts to be inserted, solder using a selective soldering unit, and even assemble power modules, for actual value added production.

2. Support for a wide variety of parts

A wide range of units are available. Many different supply types such as radial feeders, axial feeders, trays, sticks, and loose parts are supported. A wide range of part sizes can also be supported, from 1608 (0603″) to 190×190mm, with heights up to 110mm and weighs up to 200g.

NXT III, FUJI’s Scalable Placement Platform

1. Real Modularity

The platform freely combines and rearranges units easily due to complete modularization. It makes the optimum configuration that matches production needs and keeps production going by performing offline maintenance through exchanging units.

2. High speed, high accuracy

In the increasing pursuit for accuracy and speed, we have achieved a high-speed throughput up to 42,000cph (productivity priority mode) and a high accuracy of ±0.015mm (heightened accuracy mode) for high density placements.

3. State-of-the-art placements

NXTIII achieves high-accuracy placement of ±0.025mm at 35,000cph is possible even for the next generation of 0201mm (008004″) parts. PoP placement and die placement can be supported by loading a dip flux unit.

4. Cost performance

Always ensures a stable amount of solder by using the automatic solder supply function. A unit for directly setting solder cups is also available, and the cost of maintenance and the operation time can be reduced by eliminating needless filling work.

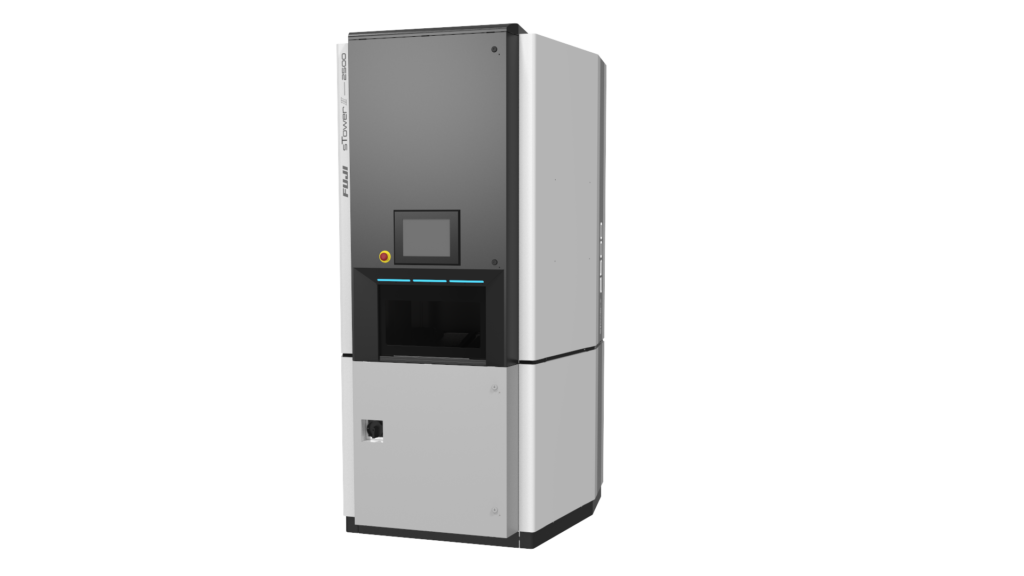

sTower II Automated Warehouse

The three models of sTower II are suited to different installation locations and offer different storage capacities.

1. By checking out the required parts automatically based on work orders, the amount of work required for part picking and management is reduced.

2. The quantity of parts contained in stored reels is kept and the occurrence of unnecessary partial reels is reduced with thorough first-in first-out management.

3. It is possible to manage the temperature and humidity as an option.

4. These slim towers are designed to fit in seamlessly at the line side.