ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Rexxam Bolsters Production in Thailand, India

Rexxam Co., Ltd. has been strengthening its global production system with expansion of the Thai and Indian factories. The company’s new Thai Factory, which started its operation in 2020, is adding a new factory building. Moreover, the company will start production at an Indian joint venture this year.

Business Activities

Rexxam has been deploying diverse manufacturing businesses. This includes printed circuit board assembly (PCBA) automated optical inspection (AOI) systems, electronic manufacturing services (EMS), and semiconductor-related equipment.

The company’s EMS business covers a wide range of equipment from air conditioning systems to consumer electronics, factory automation (FA) equipment, automotive electronics, and medical equipment.

In 2020, total sales of the company dropped about 10 percent from the previous year mainly caused by the COVID-19 pandemic. “However, we made a V-shaped recovery in sales in 2021, posting a new record,” says Hiroyuki Sumida, Vice-President, Rexxam Co., Ltd.

In another front, global supply shortages of electronic components since the beginning of 2021 prevented the company from churning out enough products. “Thus, unfilled orders have been increasing day by day,” says Sumida.

New Factory Buildings

At Rexxam Thailand, new factory buildings (A building and B building with a total floor area of 10,000sq.m.) were completed in April 2020. It started operations with three lines and 260 workers. At present, four lines are being operated in Thailand by 300 workers. Now, the company is adding another factory building with a total floor area of 10,000sq.m to meet increasing orders.

Moreover, the company will re-start production activities of a joint venture with Dixon (India) at the beginning of 2022.

Japan Production

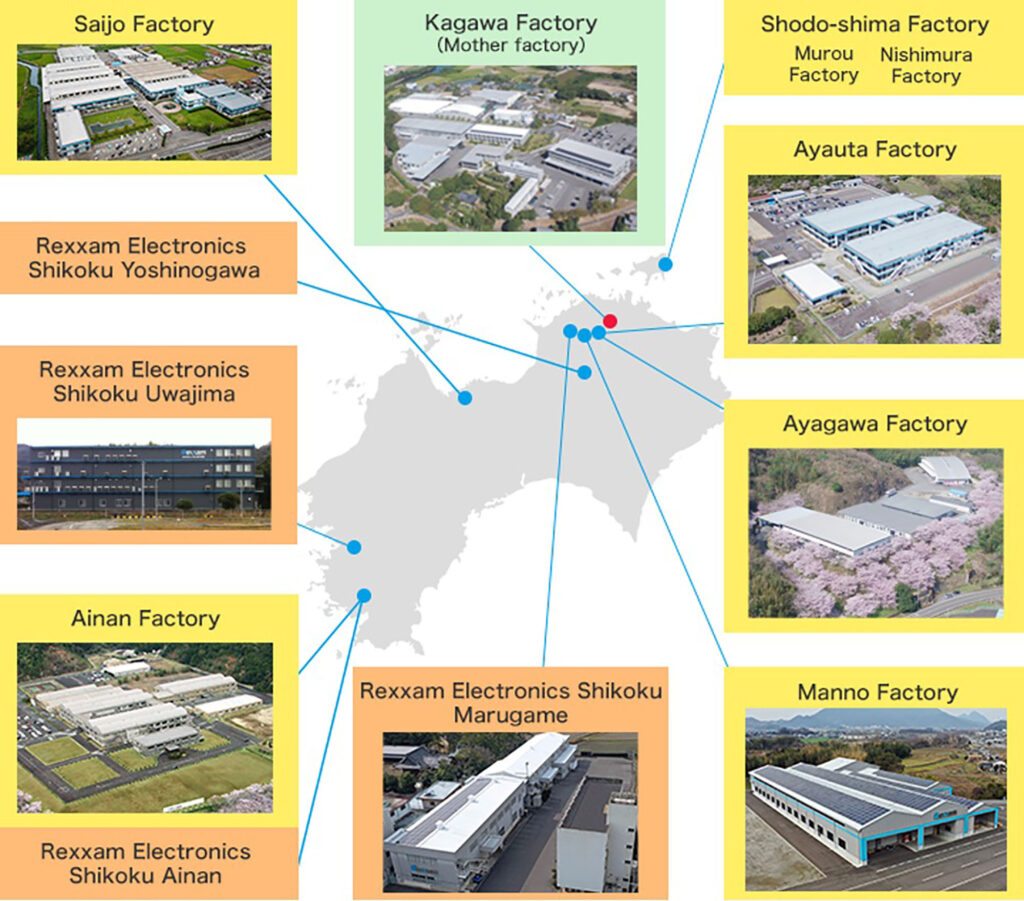

In Japan, Rexxam manufactures boards/application products for various microcontrollers; ophthalmic testing equipment, lens meters, bioanalyzer equipment, PCBA AOI systems, wafer transfer robots, hot and cold water generators for semiconductor equipment; and chemical indirect temperature controllers. The company manufactures them at its Kagawa Factory in Shikoku.

Rexxam has been converging its mounting division to Saijo Factory to enhance the efficient use of equipment and human resources. The company has also been actively investing in plants and equipment, putting in place a system for further increase in production.

Aside from these two factories, eight other factories are operating in Shikoku.

Operations Outside of Japan

Overseas, the Japanese company has the following subsidiaries: ShenZhen Shinelong Electronics Industrial Co., Ltd.; Rexxam Electronics (Suzhou) Co., Ltd.; Rexxam Thailand Co., Ltd. in Thailand; Dixon (India) Co., Ltd., an Indian partner company; and Rexxam Czech s.r.o. in Europe as production bases. These overseas bases deploy production activities targeting globally expanding Japanese companies.

Rexxam has installed the most advanced mounters that support minute surface mount components, in particular, multilayer ceramic capacitors (MLCCs) in the mounting lines of ShenZhen Shinelong Electronics Industrial and Rexxam Electronics (Suzhou), to support high-density mounting boards.